Tube-shell type heat exchange unit

A technology of shell-and-tube heat exchange and shell-and-tube heat exchanger, which is applied in the field of heat exchange units and shell-and-tube heat exchange units, and can solve problems such as large throttling loss, steam-water impact, and safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A shell-and-tube heat exchange unit includes an internal system and an external structure.

[0021] The internal system includes an intelligent control center 101, a temperature measurement unit 102, a flow measurement unit 103, a volume control unit 104, and a pressure measurement unit 106. The output terminal of the intelligent control center 101 is connected to the volume control unit 104, and the The input end of the intelligent control center 101 is connected with the temperature measuring unit 102 , the pressure measuring unit 106 and the flow measuring unit 103 .

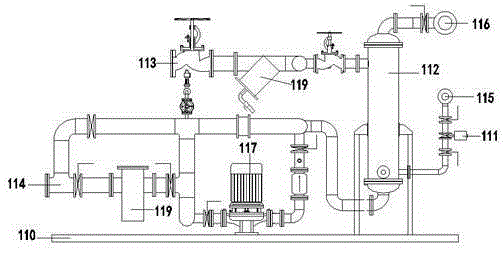

[0022] The external structure includes a base 110, an electric regulating valve 111, a shell-and-tube heat exchanger 112, a primary side inlet 113, a secondary side inlet 114, a primary side outlet 115, a secondary side outlet 116, 4 flow meters, 4 Temperature sensor, 4 pressure sensors, several valves, circulation pump 117, water supply pump 118; the shell-and-tube heat exchanger 112 includes a shell ...

Embodiment 2

[0029] A shell-and-tube heat exchange unit includes an internal system and an external structure.

[0030] The internal system includes an intelligent control center 101, a temperature measurement unit 102, a flow measurement unit 103, a volume control unit 104, a heating unit 105, and a pressure measurement unit 106. The output terminal of the intelligent control center 101 is connected to the volume control unit 104. The heating unit 105 is connected, and the input end of the intelligent control center 101 is connected to the temperature measuring unit 102, the flow measuring unit 103, and the pressure measuring unit 106.

[0031] The external structure includes a base 110, an electric regulating valve 111, two shell-and-tube heat exchangers 112, a primary side inlet 113, a secondary side inlet 114, a primary side outlet 115, a secondary side outlet 116, 4 flowmeters, 4 temperature sensors, 4 pressure sensors, several valves, 3 circulation pumps 117, 2 supplementary water pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com