Torque Wrench Life Tester

A technology of life test and torque wrench, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., to achieve the effects of high work efficiency, low work intensity and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

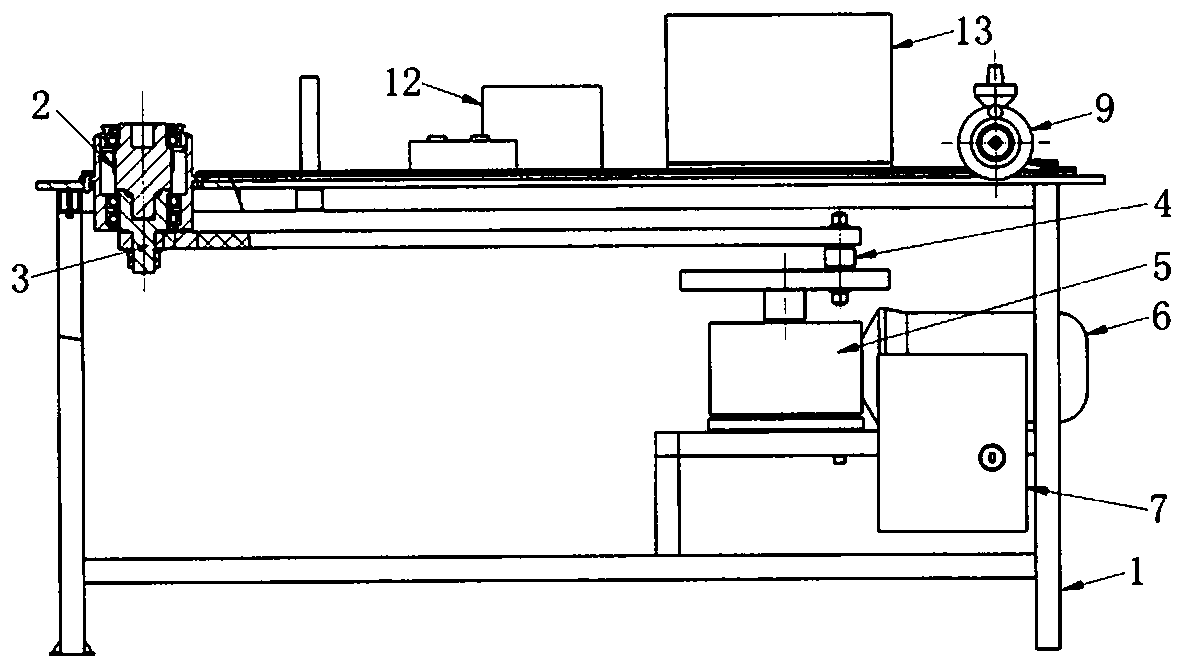

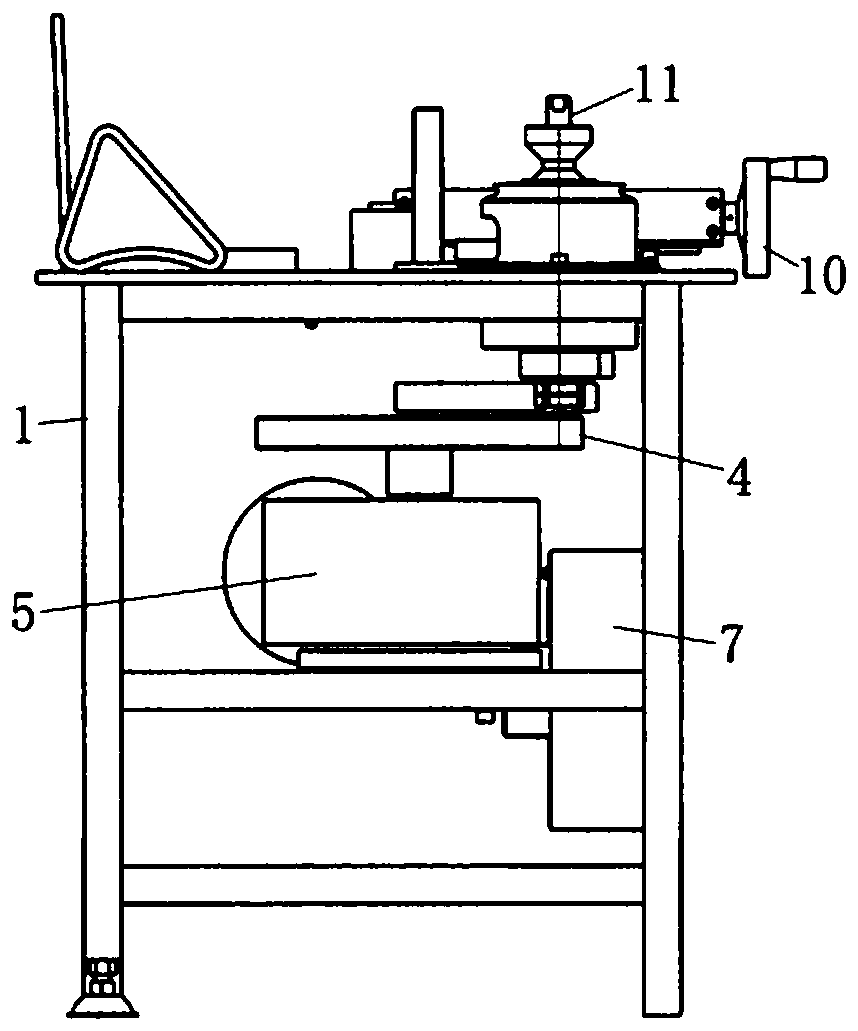

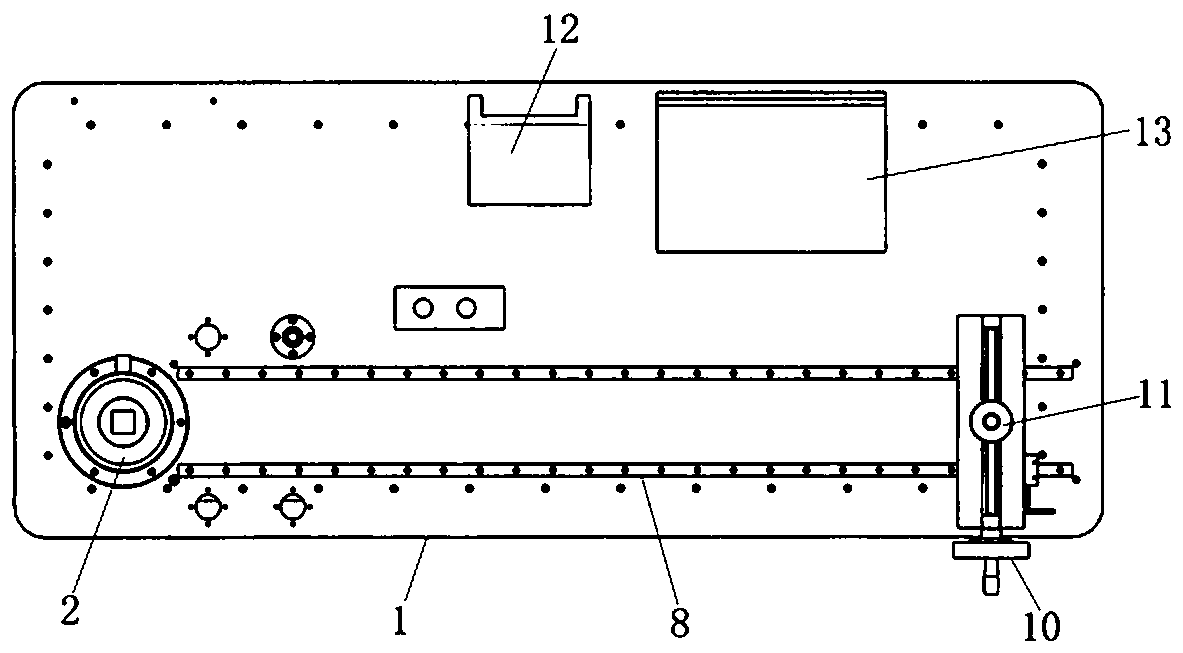

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] like Figure 1-3 As shown, a torque wrench life testing machine includes a test table 1, a torque testing mechanism, a torque loading mechanism 9 and an electric control cabinet 7. The test table 1 includes a table frame and a work surface arranged on the table frame, and the torque testing mechanism includes The torque sensor 2, the drive adapter 3, the crank linkage mechanism 4, the reduction box 5 and the motor 6, the worktable is provided with a hollow mounting frame, and the torque sensor 2 and the drive adapter 3 are all installed in the middle cavity of the mounting frame through bearings, The drive adapter 3 is located below the torque sensor 2, the convex square head at the lower end of the torque sensor 2 extends into the concave square hole on the upper end surface of the drive adapter 3, the reduction box 5 and the motor 6 are fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com