Oil-immersed high-power non-inductive resistor

A non-inductive resistance, high-power technology, applied in the field of power devices, can solve the problems of poor resistance to short-term impact current and large area occupied by high-power non-inductive resistors, so as to improve the insulation strength and increase the resistance to short-term impact Performance, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

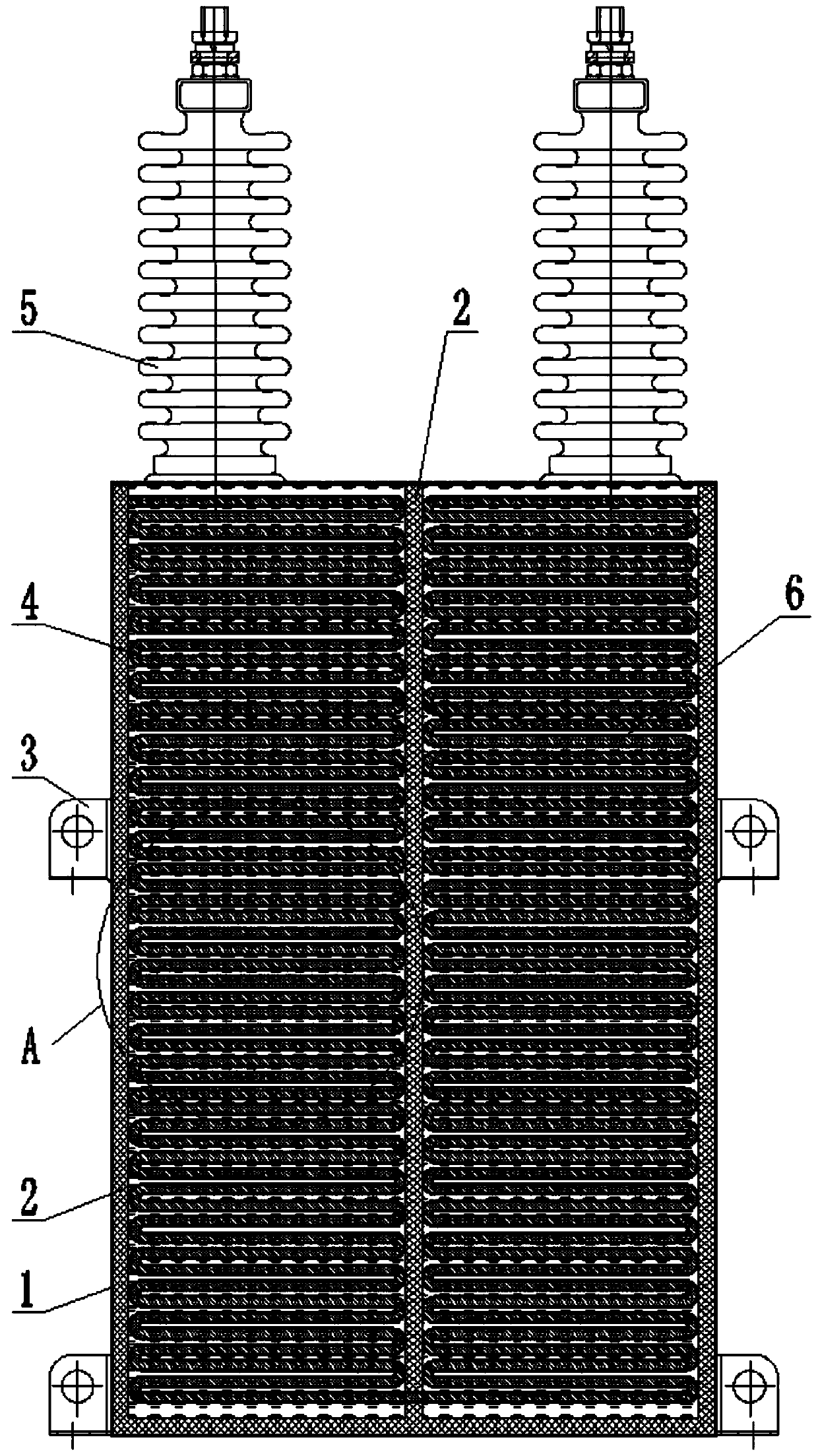

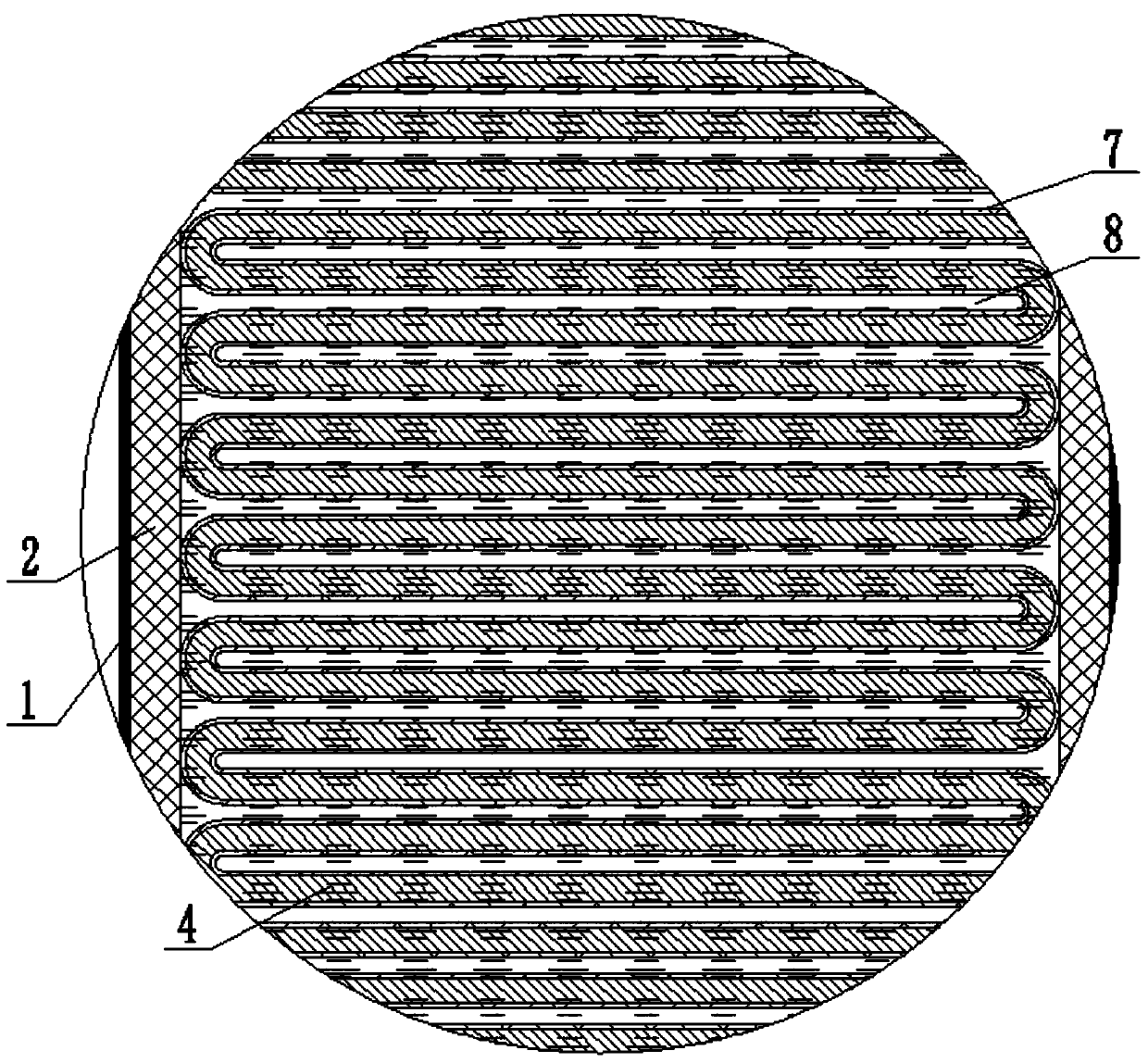

[0017] As shown in the figure, the oil-immersed high-power non-inductive resistor includes a resistance element made of nickel-chromium alloy, and the resistance element is packaged in a stainless steel shell 1. An electrical laminate 2 is provided and the electrical laminate 2 in the middle divides the stainless steel casing 1 into an inlet chamber and an outlet chamber. Composed of resistance unit II6, the resistance unit I4 and resistance unit II6 are closely arranged in a continuous S-shape along the length direction and the direction of the arrangement is opposite. In order to facilitate the passage of resistance elements, the stainless steel shell 1 is separated into the The bottom of the electrical laminate 2 entering the chamber and leading out the chamber is provided with a through hole corresponding to the resistance element, and the resistance unit I4 and the resistance unit II6 are respectively formed by a plurality of resistance segments arranged in an S shape conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com