Laminated metallic film capacitor and preparing method thereof

A metallized film, metal film technology, applied in the direction of film/thick film capacitors, multilayer capacitors, fixed capacitor electrodes, etc., can solve the problems of low mechanical strength, low dielectric constant, poor film formation, etc., to achieve low production costs , the effect of low resistivity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

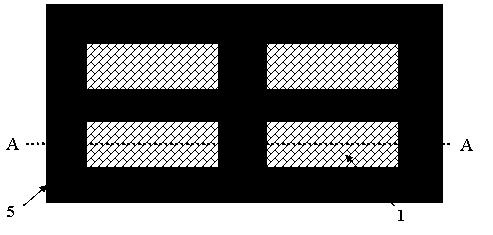

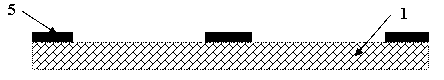

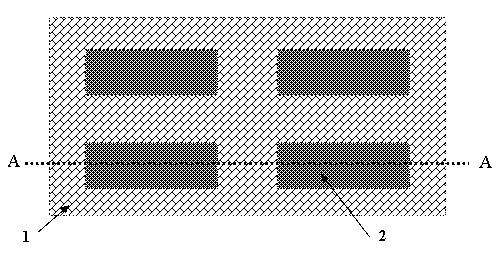

[0038] Embodiment 1 of the present invention: the structure of the laminated metallized film capacitor is as follows Figure 14 As shown, it includes an insulating substrate 1 made of alumina, and a metal thin film electrode made of tantalum is arranged on the insulating substrate 1 2 and metal thin film electrodes made of tantalum 3. On metal thin film electrodes 2 with metal thin film electrodes 3 is provided with a dielectric film 4 that completely separates them. The dielectric film 4 is made of tantalum pentoxide, and the metal film electrode 2. Metal thin film electrode 3 and the dielectric film 4 form a laminated structure, and the metal film electrode 2 with lead-out electrodes 8. On metal thin film electrodes 3 is equipped with lead-out electrodes 9; A passivation protection layer is provided outside the laminated structure.

[0039] A method for manufacturing a laminated metallized film capacitor,

[0040] Step 1. Lay a deposition mask I5 on a cl...

Embodiment 2

[0046] Embodiment 2 of the present invention: the manufacturing method of laminated metallized film capacitor,

[0047] Step 1. Lay a deposition mask I5 on a clean aluminum nitride substrate (the design of the deposition mask 5 is based on the requirements of technical parameters such as capacitor specifications, models, and capacitance values), and deposit a thickness of about 0.20 microns by magnetron sputtering. Metal thin film electrodes made of niobium metal 2; After the deposition is completed, the metal thin film electrode 2 Heat treatment at 700°C for about 30 minutes to obtain a uniform and dense metal thin film electrode 2;

[0048] Step 2. On the basis of step 1, select the metal electrode layer mask 6, and use the magnetron sputtering method to deposit a niobium pentoxide dielectric film 4 with a thickness of about 0.08 micron; ℃ heat treatment for about 30 minutes to obtain a uniform and dense dielectric film 4;

[0049] Step 3. On the basis of step 2, s...

Embodiment 3

[0053] Embodiment 3 of the present invention: the manufacturing method of laminated metallized film capacitor,

[0054] Step 1. Lay a deposition mask I5 on a clean silicon dioxide substrate (the design of the deposition mask 5 is based on the requirements of technical parameters such as capacitor specifications, models, and capacitance values), and deposit a thickness of about 0.30 microns by magnetron sputtering. Metal thin film electrodes prepared from copper-silver alloy 2; After the deposition is completed, the metal thin film electrode 2 Heat treatment at 700°C for about 30 minutes to obtain a uniform and dense metal thin film electrode 2;

[0055] Step 2. On the basis of step 1, select the metal electrode layer mask 6, and deposit an aluminum oxide dielectric film 4 with a thickness of about 0.12 microns by magnetron sputtering; after the deposition is completed, heat-treat the dielectric film 4 at 700°C About 30 minutes to obtain a uniform and dense dielectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com