Cleaning tool for optical connector

A technology for optical connectors and cleaning tools, which is applied in the field of optical connector cleaning tools, can solve the problems of complex cleaning work of cleaning tools, and achieve the effects of simple structure, simplified operation, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

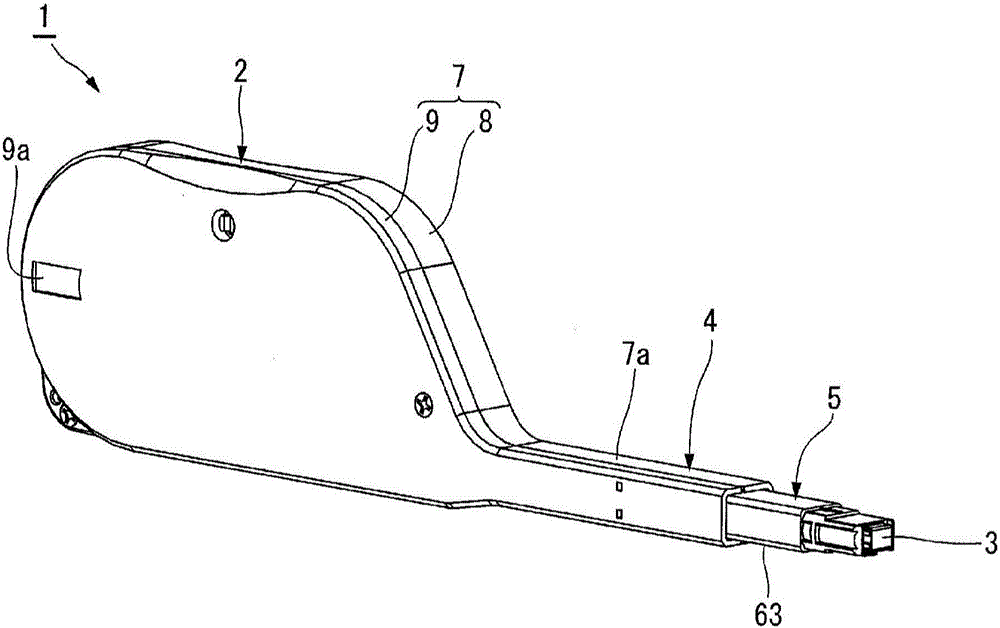

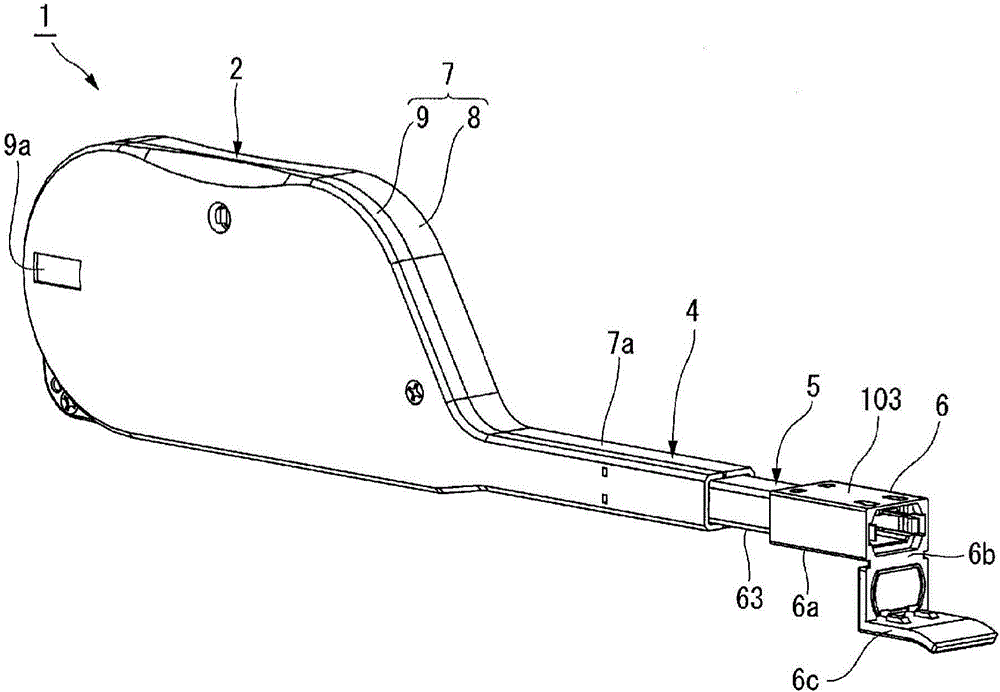

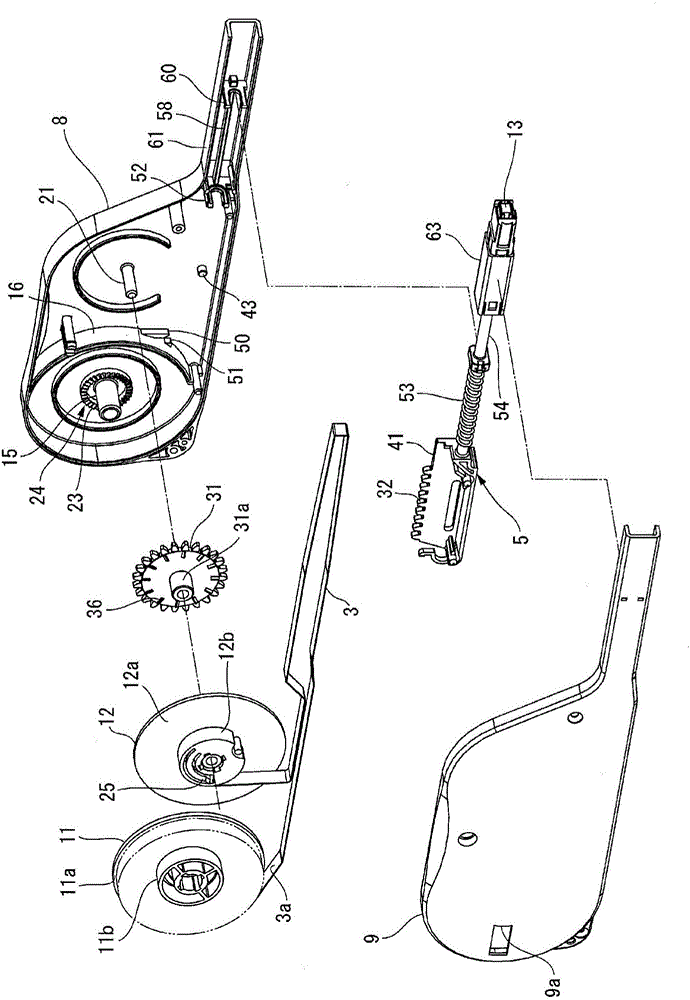

[0050] The following will refer to Figures 1 to 26 An embodiment of the optical connector cleaning tool according to the present invention will be described.

[0051] Such as figure 1 The optical connector cleaning tool 1 shown consists of a figure 1 The left handle 2. A user (not shown) holds handle 2 in his or her hand, and will figure 1 The cleaning cloth 3 with the exposed end on the right side is pressed against the connection end surface of the optical connector plug (not shown), thereby cleaning the connection end surface. In this embodiment, the direction toward the optical connector plug will be referred to as forward (towards figure 1to the lower right of the ), and the opposite direction will be called backward. Also, when explaining respective components to be described below, a member positioned forward as described above will be referred to as a front portion or a front side, and a member positioned backward will be referred to as a rear portion or a rear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com