A mobile silage device

A mobile, silage technology, applied in the field of animal husbandry, can solve the problems of perishable and deteriorating silage bags, high investment in conventional silage, complex facilities, etc., to save human and material resources, solve high investment, and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

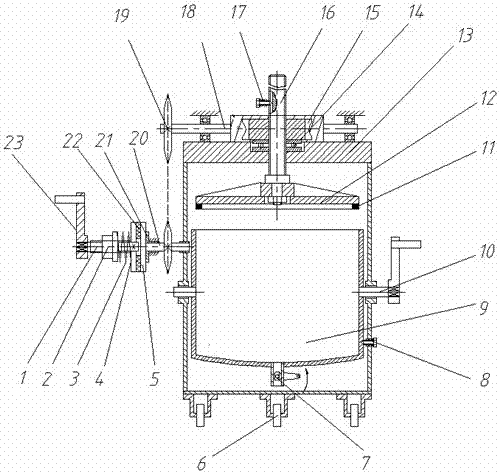

[0040] Such as figure 1 as shown,

[0041] The movable silage device of the present invention discloses a movable silage device, which is characterized in that it comprises a frame 13, a bucket body 9 with an upper opening, a sealing and pressing mechanism, an operating mechanism and a moving mechanism;

[0042] The barrel body 9 is located inside the frame 13, and a support shaft 10 is respectively set on the opposite side of the outer side of the middle part of the barrel body, and the barrel body 9 is connected to the frame 13 by the support shaft 10 rotation; 9 locking screws 8; the bottom of the staving 9 is provided with a ventilation and drainage valve;

[0043] The top of the frame 13 is provided with a sealing and pressing mechanism. The sealing and pressing mechanism includes a bung 12 arranged directly above the barrel body 9, a screw shaft 16 vertically threaded on the top of the bung 12, and a worm gear connected to the screw shaft by threads. 15. The worm shaft...

specific Embodiment 2

[0051] According to the movable silage device in embodiment 1, the device is provided with a control system comprising:

[0052] The pressing unit includes a frame 13, a barrel body 9 with an upper opening, a sealing and pressing mechanism, and an operating mechanism; the barrel body 9 is connected to the inside of the frame 13 through a support shaft 10; a ventilation and drainage valve is provided at the bottom of the barrel body 9 7. A sealing and pressing mechanism is provided on the top of the frame 13. The sealing and pressing mechanism includes a barrel cover 12 arranged directly above the barrel body 9, a screw shaft 16 vertically threaded on the top of the barrel cover 12, and a screw shaft threadedly connected to the screw shaft. Worm wheel 15, the worm shaft 18 that is threadedly connected with worm wheel 15; One end of worm shaft 18 is provided with driven sprocket; The bottom edge of bung 12 is provided with sealing ring 11; The outer diameter of bung 12 is not lar...

specific Embodiment 3

[0059] According to the control system of movable silage device in embodiment 2, the control method of this control system:

[0060] (1), the control unit controls the atomizing spray gun of the disinfection unit to spray 50-75ml of potassium permanganate solution with a concentration of 0.28%-0.32% into the barrel body 9; after completion, the barrel cover 12 goes down and covers the barrel body 9. Seal for 10-12 minutes to complete the disinfection;

[0061] (2) The control unit opens the barrel body 9 and tilts the barrel body 45°-60°; the silage is cut and put into the barrel body 9, and the control unit controls the opening of the control valve and solenoid valve of the fermentation unit, 9 Add bran and silage additives and mix it into 15-20kg silage, and make the moisture content in the silage lower than 40%; the silage includes 20-25 parts of silage, 15-20 parts of bran and 1- 1.5 parts of silage additive;

[0062] (3) Control the mixing motor to swing at a constant s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com