A fixture device

A fixture and fixture table technology, applied in the field of fixtures, can solve problems affecting the quality of tobacco leaf curing, waste of production labor, uneven density, etc., and achieve the effects of facilitating production automation, preventing tobacco leaves from falling off, and simplifying the weaving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

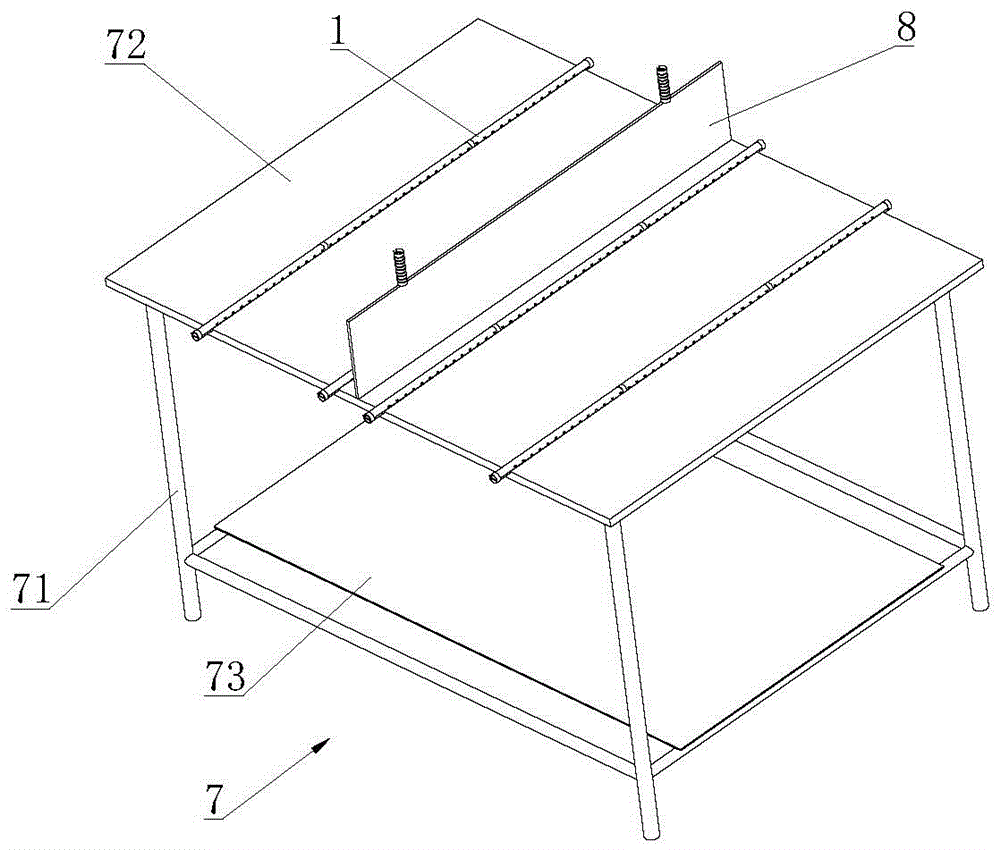

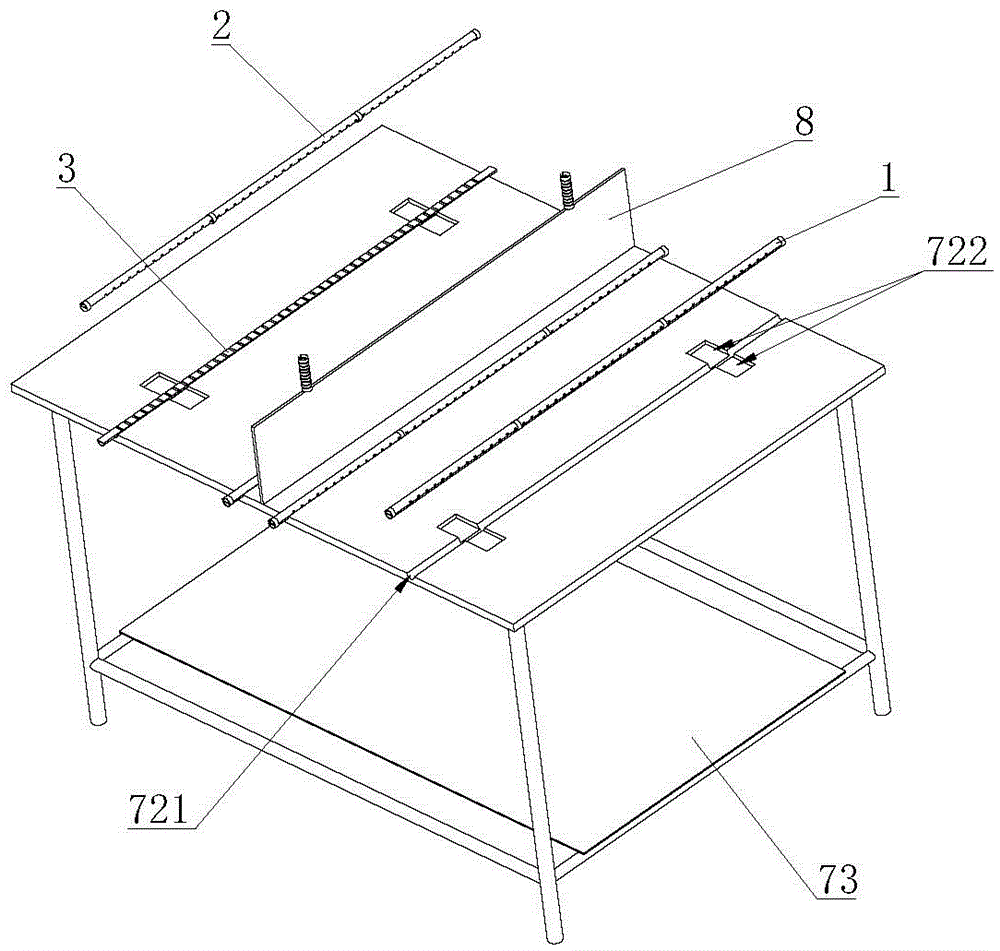

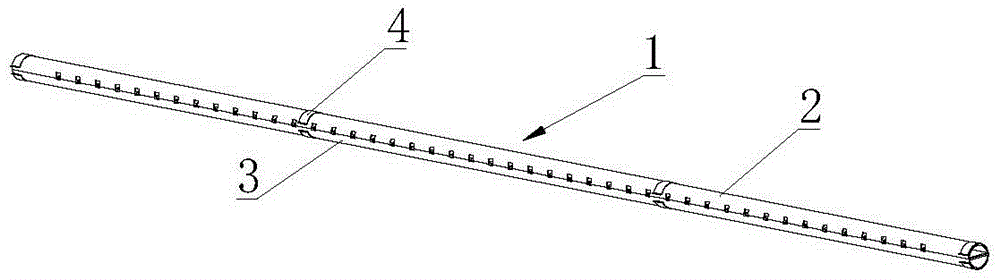

[0024] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

[0025] Such as Figure 1 to Figure 5 As shown, a fixture device includes a fixture body 1, and the fixture body 1 includes a fixture upper half 2, a fixture lower half 3, and is used for locking the fixture upper half 2 and the fixture lower half. The clamp locker of the block 3, the upper half 2 of the clamp is provided with several upper clamping grooves 21, and the lower half 3 of the clamp is provided with a lower clamping groove 31 corresponding to the upper clamping groove 21, when When clamping the material, the upper clamping groove 21 is matched with the lower clamping groove 31 .

[0026] In practical applications, the material can be tobacco leaves. Place the lower half 3 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com