Full-automatic material collecting device of gravure color press and application method for full-automatic material collecting device

A technology of splicing device and color printing machine, which is applied in gravure rotary printing machine, printing machine, rotary printing machine and other directions, can solve the problems of increasing manpower load, low work efficiency, economic loss, etc. The effect of convenient feeding and stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

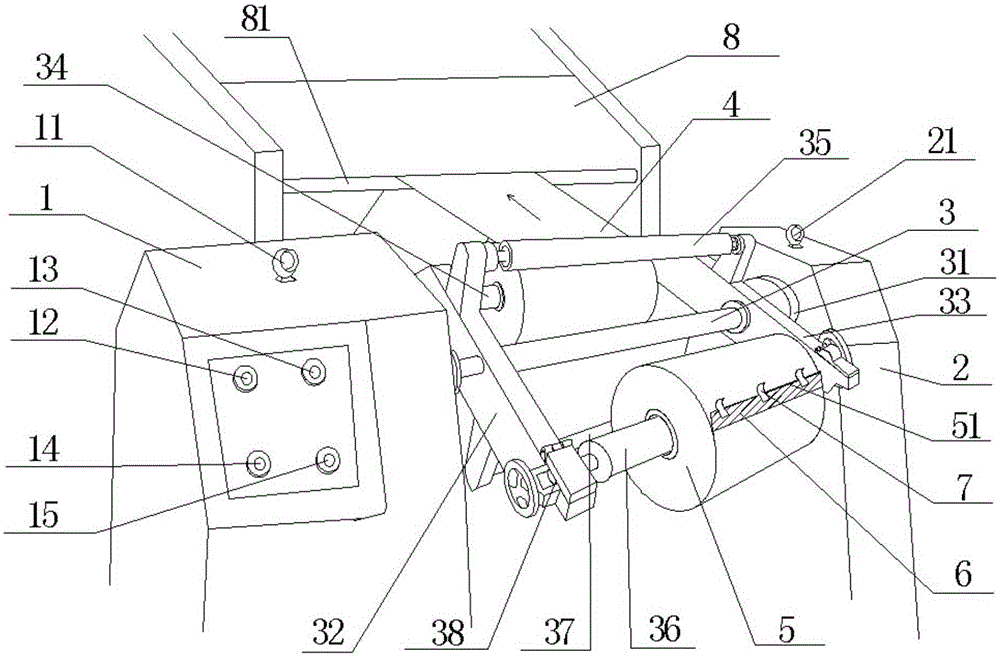

[0020] Such as figure 1 , a fully automatic material receiving device for a gravure color printing machine, comprising a left base 1, a right base 2, and a shaft 3, the shaft 3 is located between the left base 1 and the right base 2, and the shaft 3 Both ends are provided with a main rotating shaft 31 and are connected to the left base 1 and the right base 2 through the main rotating shaft 31. The shaft 3 is provided with a left rotating arm 32 and a right rotating arm 33. The left rotating arm 32, Between the two ends of the right turning arm 33, a first turning roller 34, a first auxiliary turning roller 35, a second turning roller 36, and a second auxiliary turning roller 37 are arranged, and the first turning roller 34, the second turning roller 36 Both ends are provided with a slave shaft 38 . The left side base 1 is provided with a power switch 12, a rotary switch 13 of the shaft rod 3, a rotary switch 14 of the first roller 34, and a rotary switch 15 of the second roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com