Piezoelectric array spray head and spraying equipment including the same

A piezoelectric array and nozzle technology, applied in the field of piezoelectric ceramics, can solve the problems of low physical resolution, narrow application range, and inability to adjust, and achieve the effect of high physical resolution, wide application range, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a detailed description will be given below in conjunction with the drawings and specific embodiments.

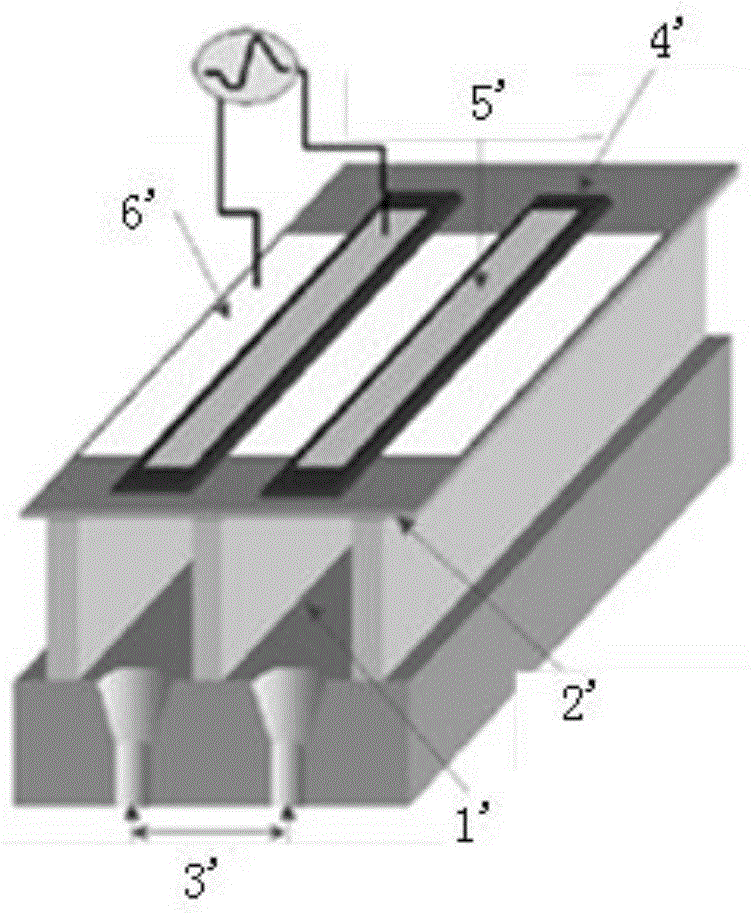

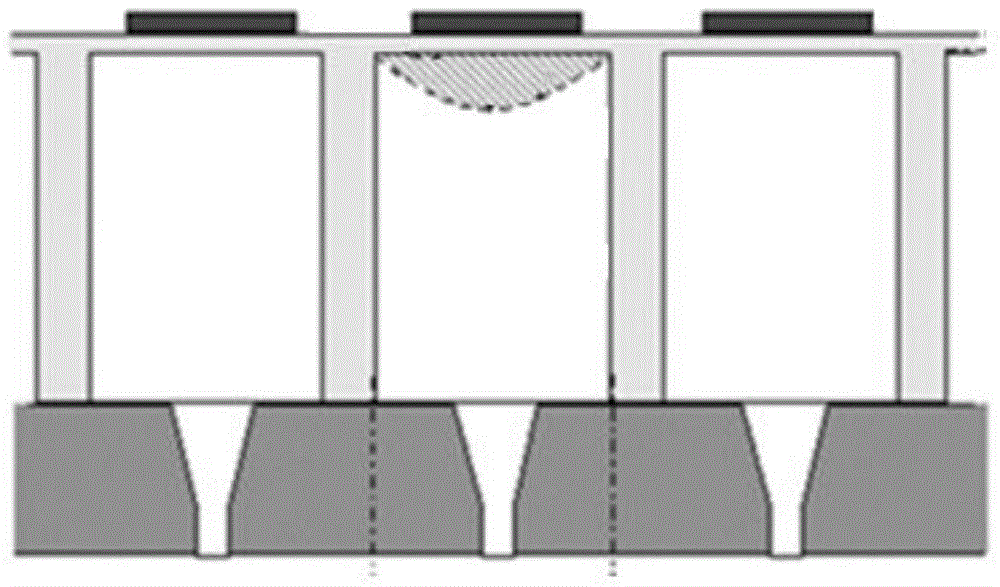

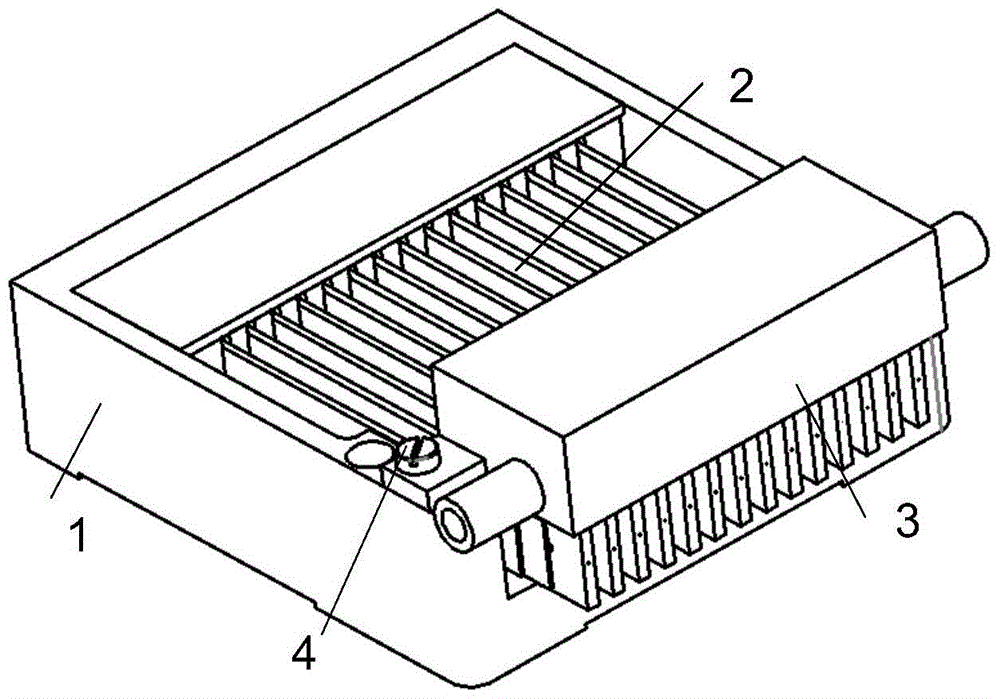

[0037] In one aspect, the present invention provides a piezoelectric array nozzle, such as Figure 3 to Figure 7 As shown, the nozzle power part 2 and the nozzle ink part 3 are included, and the nozzle ink part 3 includes a plurality of sheet-shaped and parallel inkjet chambers 32;

[0038] Each ink jet cavity 32 is provided with an ink inlet 324, an ink outlet 325, and a nozzle 326. The nozzle 326 is located on an end surface of the ink jet cavity 32 parallel to the thickness direction. The ink jet cavity 32 is perpendicular to the thickness direction. The two side walls are flexible side walls 322;

[0039] The nozzle power part 2 adopts a piezoelectric ceramic cantilever beam 23, one end of the piezoelectric ceramic cantilever beam 23 is fixed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com