Efficient T-ingot band saw sawing equipment based on energy conservation and environmental protection

An energy-saving, environmentally friendly and high-efficiency technology, which is applied in metal sawing equipment, metal processing equipment, sawing machine devices, etc., can solve the problems of increasing band saw blade breakage, reducing the service life of the band saw blade, and unable to change the toughness of the band saw cutting section. Reduced risk of breakage and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

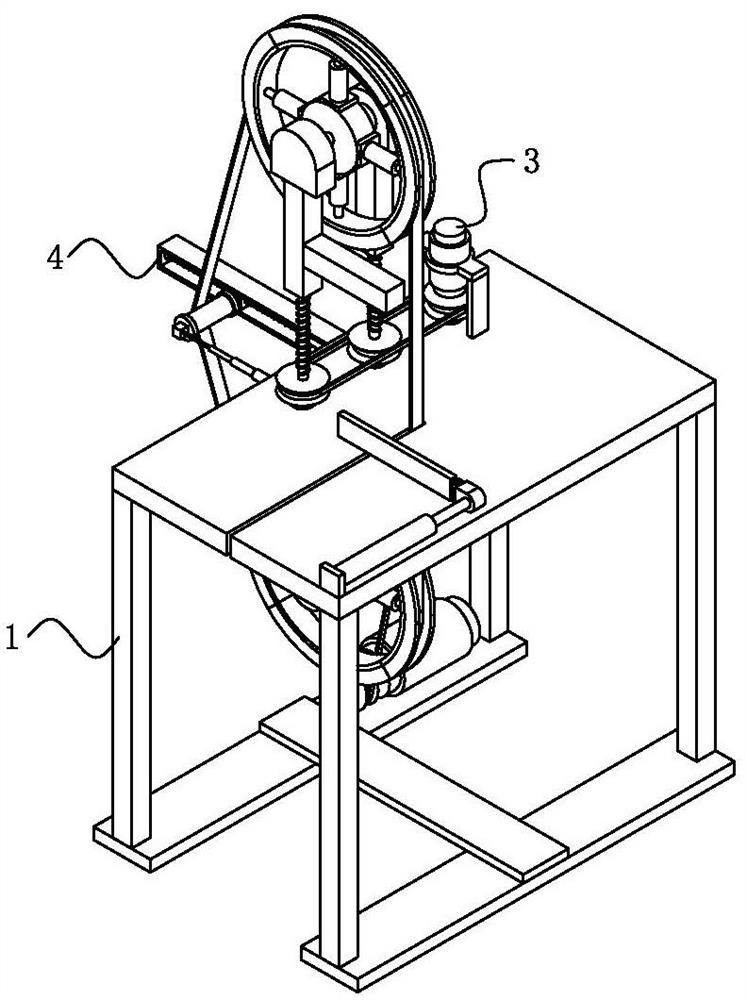

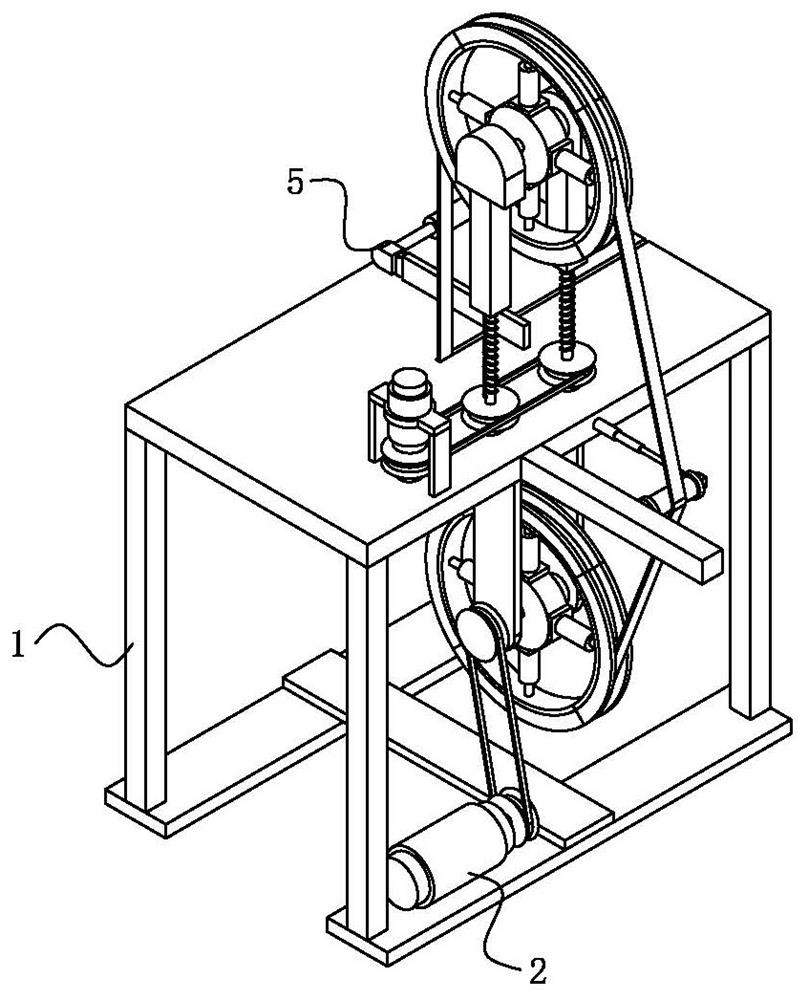

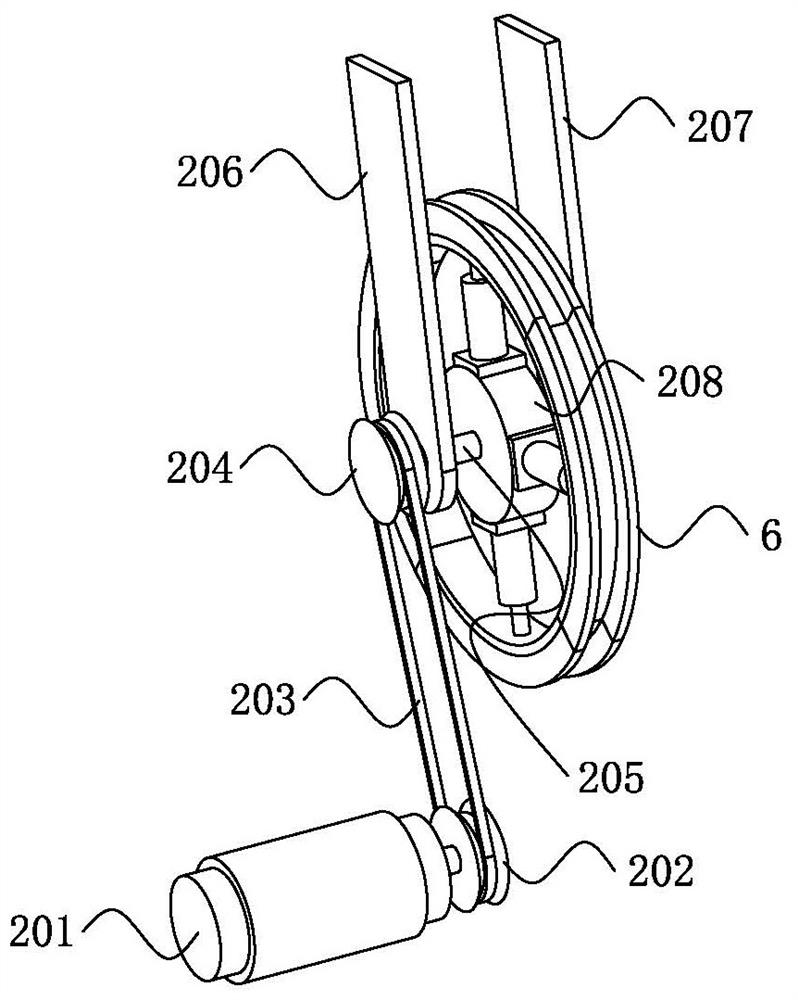

[0035] see Figure 1-8 As shown, the present invention is a high-efficiency T-spindle band sawing equipment based on energy saving and environmental protection. The hoisting plate B207, the hoisting plate A206 and the hoisting plate B207 are relatively arranged, and the top ends are all welded on the bottom of the workbench 1, and the lower saw wheel 208 is installed between the hoisting plate A206 and the hoisting plate B207, behind the upper surface of the workbench 1 A lifting assembly 3 is provided on one side of the end, a pressure regulating assembly 4 is provided at the rear of the outer wall of one side of the workbench 1, and a pusher assembly 5 is provided at the corner of the front end side of the upper surface of the workbench 1, and the pusher assembly 5 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com