High-speed magnetic suspension linear propulsion system

A propulsion system and maglev technology, applied in electric traction, electric vehicles, transportation and packaging, etc., can solve the problems of poor stability and complex control of maglev propulsion system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

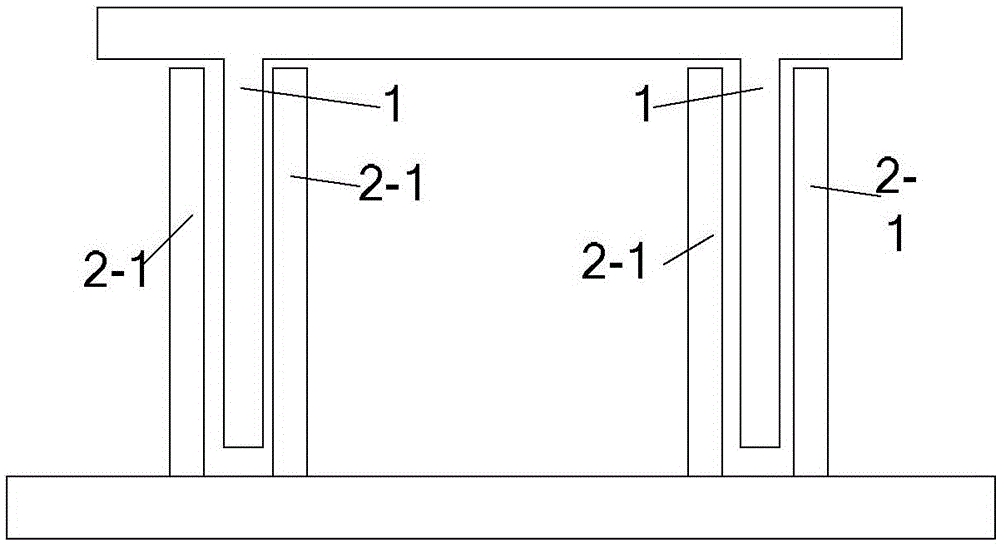

[0087] Specific Embodiment 1: This embodiment is described in conjunction with Fig. 1(a), Fig. 1(b) and Fig. 1(c), the high-speed magnetic levitation linear propulsion system described in this embodiment, the propulsion system includes a motor device, a drive control installations and auxiliary support structures;

[0088] The motor device is composed of two linear propulsion units, and each magnetic levitation linear propulsion unit is composed of a levitation guided propulsion primary and a secondary 1; each magnetic levitation linear propulsion unit is a long primary and a short secondary, and the primary is fixed, and the secondary The structure of the movement; the plane of the air gap between the primary and secondary 1 is perpendicular to the horizontal plane;

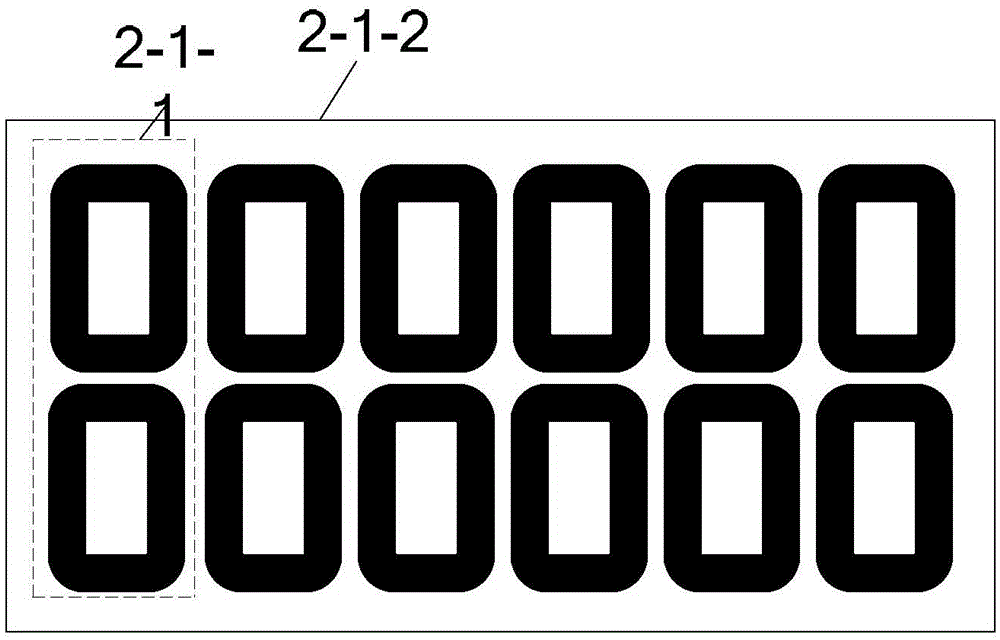

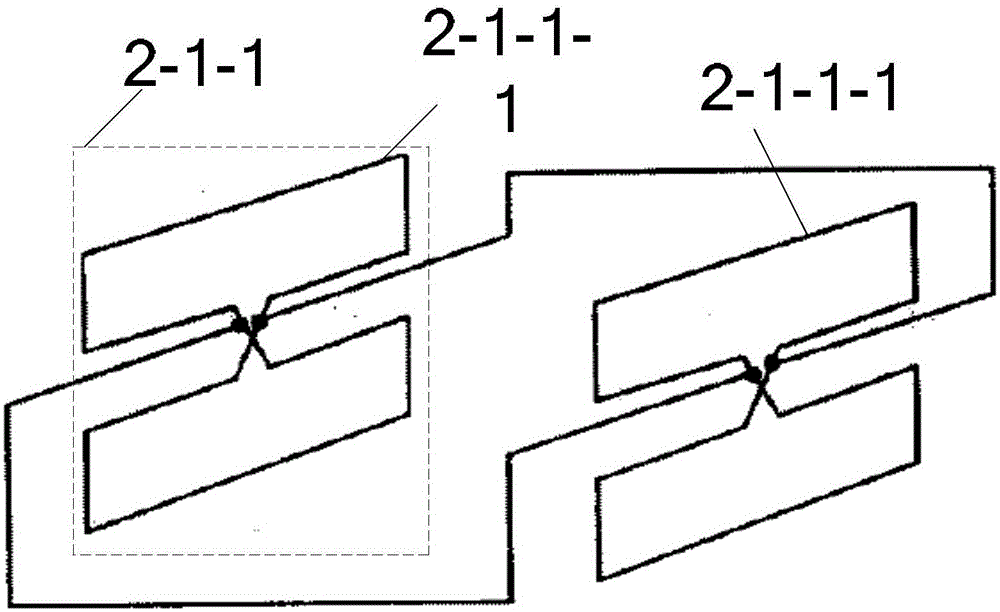

[0089] The suspension-guided propulsion primary is a bilateral structure, and the winding of each side structure 2-1 in the bilateral structure is composed of a coil group 2-1-1 and a coil substrate 2-1-2, and e...

specific Embodiment approach 2

[0096] Specific embodiment two: This embodiment is described in conjunction with Fig. 2(a) and Fig. 2(b), the high-speed maglev linear propulsion system described in this embodiment, the propulsion system includes a motor device, a drive control device and an auxiliary support structure; The motor device includes a suspension guiding primary, a propelling primary 2-2, and two secondary 1s; the motor device is a long primary, short secondary, and the primary is fixed and the secondary moves; the primary and secondary The plane where the air gap is located is perpendicular to the horizontal plane;

[0097] The primary propulsion system of the suspension guide includes a motor device, a drive control device and an auxiliary support structure;

[0098] It is a bilateral structure, and the bilateral structure is arranged symmetrically. The winding of each side structure 2-1 is composed of a coil group 2-1-1 and a coil substrate 2-1-2. Each coil group 2-1-1 is composed of two rectan...

specific Embodiment approach 3

[0108] Specific implementation mode three: combination image 3 Describe this embodiment, the high-speed maglev linear propulsion system described in this embodiment, the propulsion system includes a motor device, a drive control device and an auxiliary support structure; the motor device includes a levitation guide primary, a propulsion primary 2-2 and two Secondary 1; the motor device is a long primary, short secondary, and primary fixed, secondary movement structure; the plane where the air gap between the primary and secondary is perpendicular to the horizontal plane;

[0109] The primary propulsion system of the suspension guide includes a motor device, a drive control device and an auxiliary support structure;

[0110] It is a bilateral structure, and the bilateral structure is arranged symmetrically. The winding of each side structure 2-1 is composed of a coil group 2-1-1 and a coil substrate 2-1-2. Each coil group 2-1-1 is composed of two rectangular The coil is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com