A flow-limiting hermetic exhaust valve for aerostats and its position-limiting control method

A technology for exhaust valves and aerostats, which is applied in the field of aviation aerostats, can solve the problems of high assembly accuracy, no pre-tightening force on the valve cover, and inability to ensure airtightness, etc., so as to improve product reliability and increase Good air tightness and product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

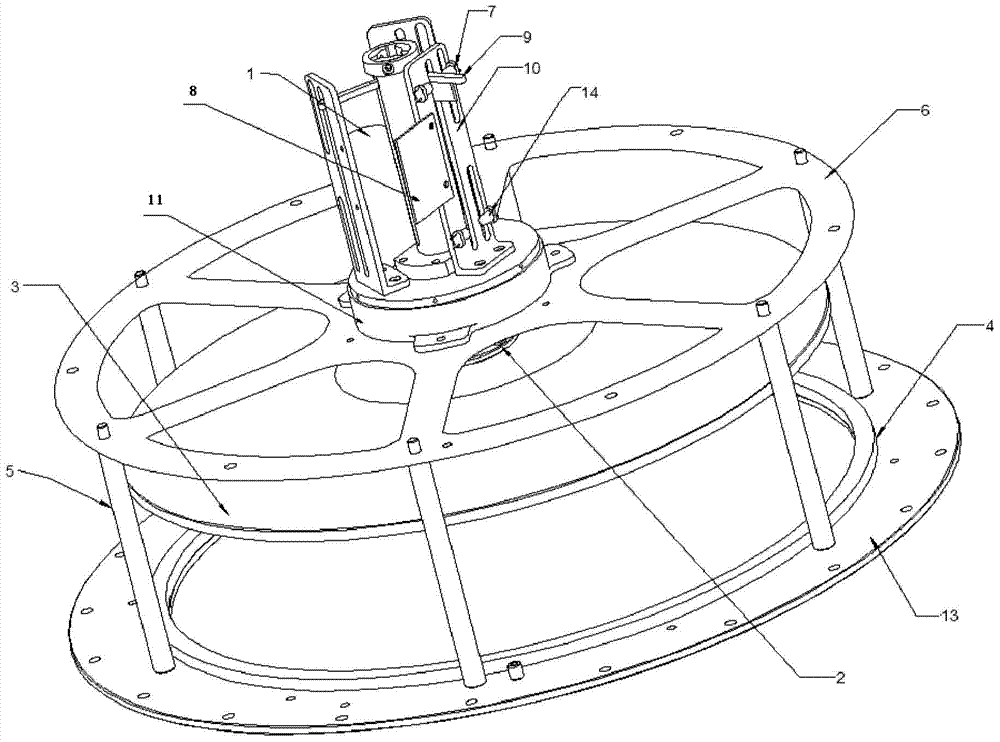

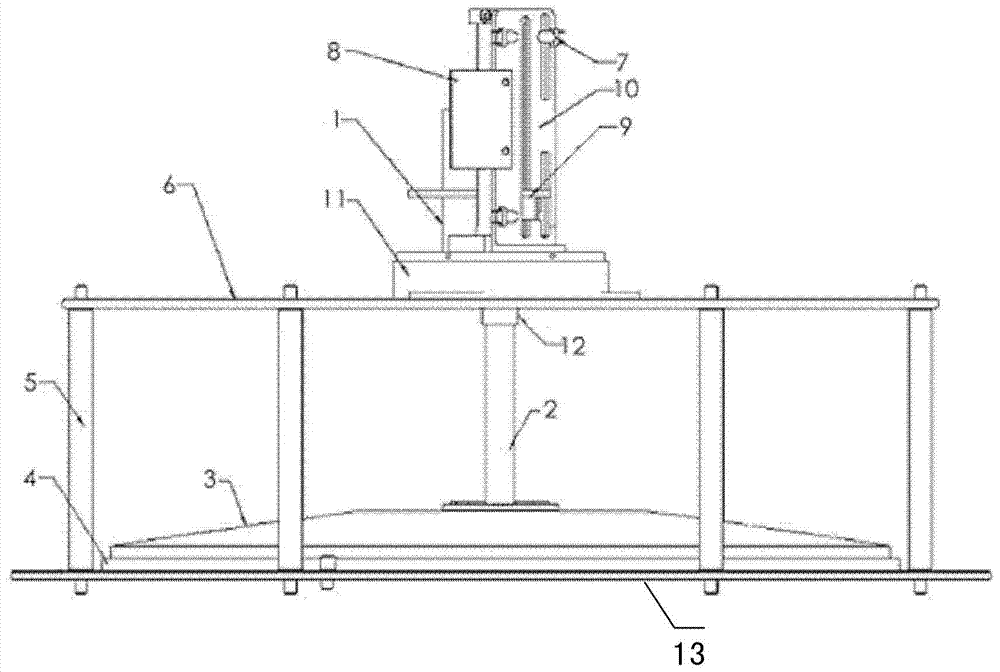

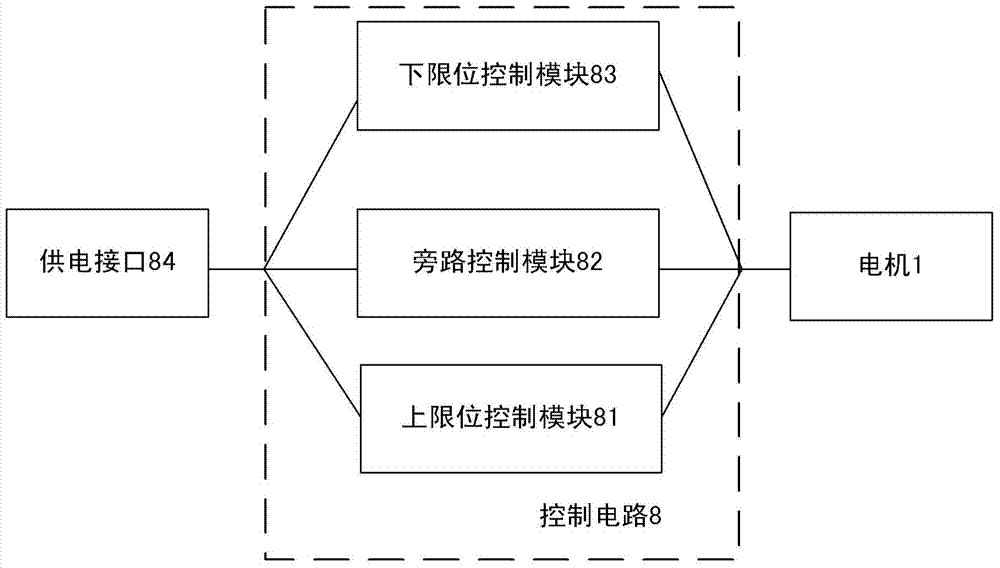

[0021] Embodiment 1: Ideally, there should be a certain pre-tightening force after the valve cover 3 is closed to ensure the airtightness of the exhaust valve, which is especially important for the helium exhaust valve of the main air bag of the aerostat. The valve cover 3 covers the sealing ring 4 and the valve port of the valve body 13; the control circuit 8 is connected to the motor 1, and is used to control the rotation of the motor 1 and limit the current of the motor 1 to automatically cut off the power supply of the motor 1; the motor 1 is connected to the valve cover 3, It is used to control the lifting and moving down of the valve cover 3 along the lead screw; the upper limit element 7 is connected to the control circuit 8; the stop block 9 is fixedly connected to the lead screw 2; when the motor 1 rotates, the stop block 9 moves up and down along the lead screw 2 , the gear block 9 is in contact with the upper limit element 7, the upper limit element 7 cuts off the co...

Embodiment 2

[0022] Embodiment 2: The upper limit of the opening of the exhaust valve only determines the degree of opening of the valve cover 3, and a slight installation error does not affect the performance of the exhaust valve. Therefore, the current control of the lower limit of the closing of the valve cover 3 is mainly considered here. After the bonnet 3 is in contact with the sealing ring 4, the current increased due to the blocked rotation of the motor 1, and after a certain level, the power is cut off. The magnitude of the current can determine the pretightening force of the bonnet 3 closing, so through the circuit design, It can be guaranteed that all the valve covers 3 produced can be closed in place, and there is a consistent pretightening force after the valve covers 3 are closed, which is beneficial to enhance the airtightness of the exhaust valve. Thus, the present invention arranges a circle of screw holes on the outer circle of the valve body 13, and relies on the screw ho...

Embodiment 3

[0023] Embodiment 3: A plurality of columns 5 are respectively located between the base 6 and the valve body 13 and the two are connected into one body, and the plurality of columns 5 are used to support the base 6 and the valve body 13; the screw 2 is connected through the screw 2 The screw holes arranged on the flange structure of the lower end face of the valve are fixedly connected with the valve cover 3, and the lead screw 2 is used for opening and closing the valve cover to leave and cover the valve port. The upper end surface of the lead screw 2 has a threaded hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com