Surface harmonic surface exposure machine

A surface aerator and harmonic technology, applied in the field of surface aerator, can solve the problems of difficult oxygen transmission, blockage of aeration pipe, low efficiency of aeration and dissolved oxygen of cutting impellers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] What is to be processed in this embodiment is an area of 6300m 2 , the plane shape is nearly circular, relatively regular, and the pond with an average water depth of 2m uses a single surface harmonic surface aerator for oxygenation treatment.

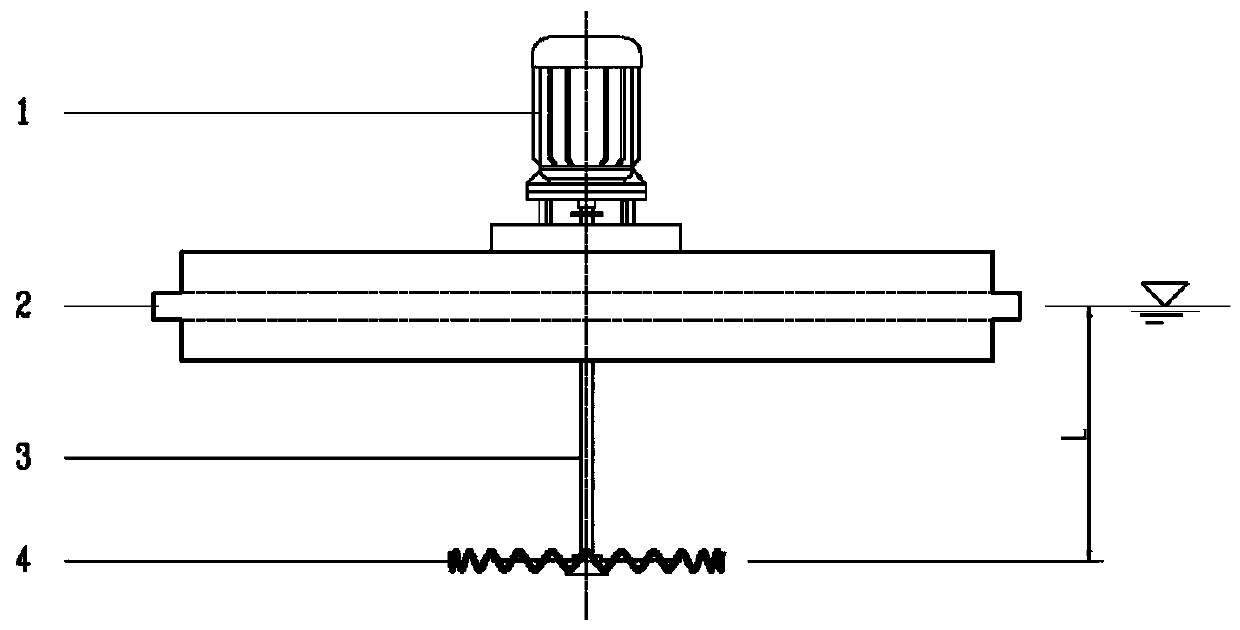

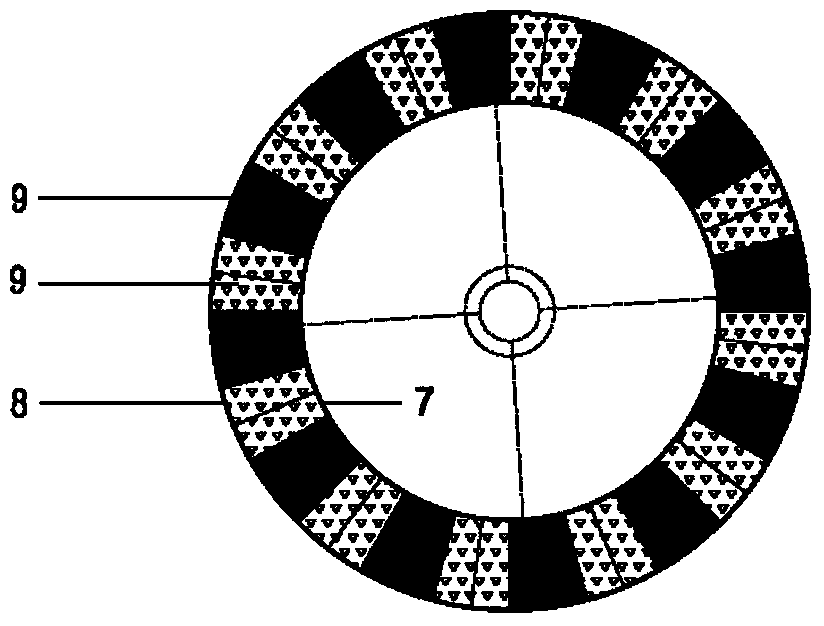

[0041] Referring to the accompanying drawings, the curved surface harmonic surface exposure machine used in this embodiment includes a motor 1 fixed on the top of the buoy 2, and a blade 4 linked with the motor 1 through a connecting rod 3. The blade 4 is arranged coaxially with the connecting rod 3 The ring, which regularly fluctuates up and down along the circumference, is in the shape of a sine wave.

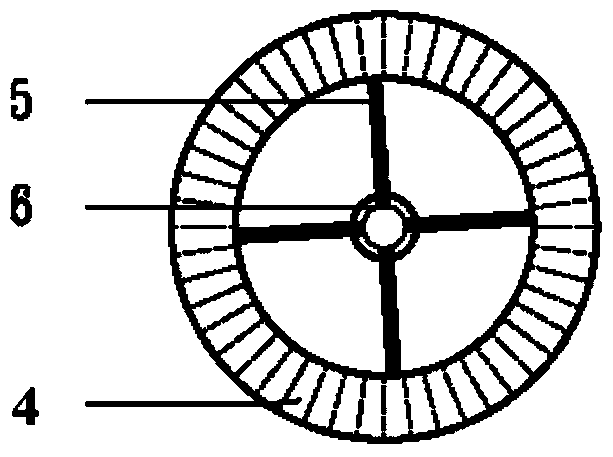

[0042] The bottom of the connecting rod 3 is provided with a fixed sleeve 6, and the blade 4 is installed on the periphery of the fixed sleeve 6 through a bracket 5. The bracket 5 is four spokes connected between the fixed sleeve 6 and the blade 4.

[0043] The connecting rod 3 extends to below the buoy 2, and the length of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com