A kind of sludge composting experimental equipment and method

A kind of experimental equipment and sludge technology, applied in the direction of sewage/sludge fertilizer, organic fertilizer preparation, organic fertilizer, etc., to achieve the effect of improving operating efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

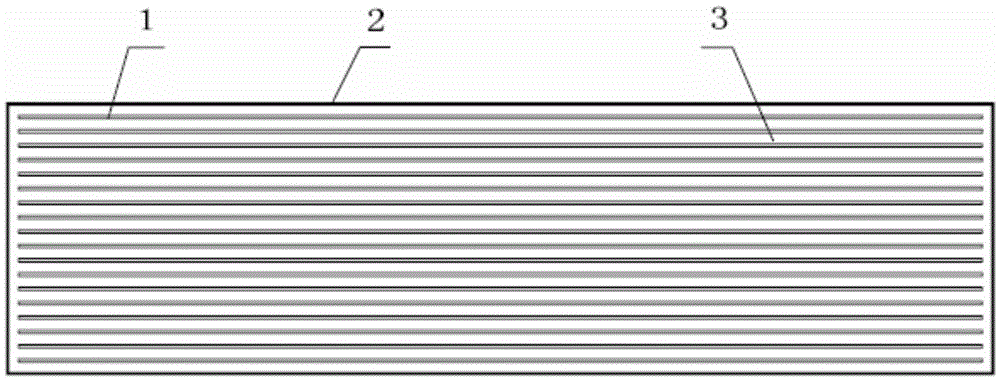

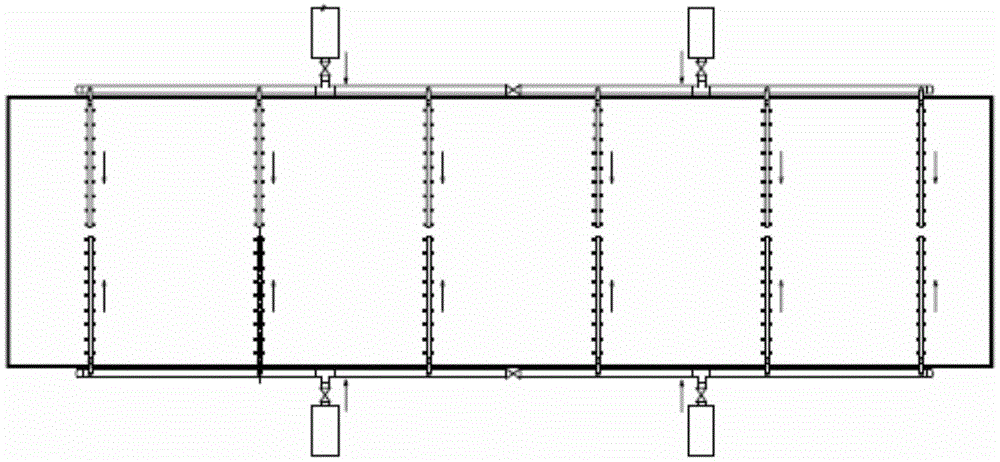

[0045] 1. The principle and purpose of the experiment: 1) Keep the completed facilities undamaged to the greatest extent. On this basis, according to our company's experience and some excellent aspects of similar projects, some key links should be properly adjusted and improved on site, such as a For the gas distribution system of the aerobic fermentation tank, in order to prevent the uneven distribution of gas from affecting the fermentation effect, according to the original design, the layout of the oxygenated gas distribution in the fermentation tank was refined, optimized and improved, and strive to use the The entire sludge aerobic fermentation pile is evenly filled with oxygen; 2) In addition to meeting the oxygen supply, the fan should also be able to adjust the temperature of the fermentation tank by adjusting the blast volume in time, so the specification of the blower should be determined through further experiments; 3 ) Verify the operation mode and structure of some...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com