Coal leveling rod

A technology of flat coal and rod body, applied in the field of flat coal rods, can solve problems such as flat coal rod sagging, achieve uniform heating, improve the effect of flat coal, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

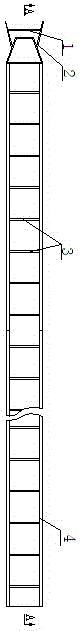

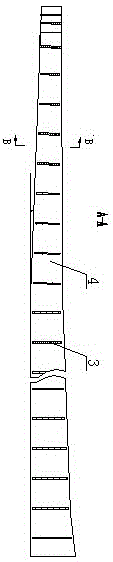

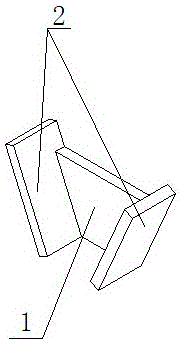

[0022] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0023] It can be seen from the accompanying drawings that a flat coal rod includes a horizontal part and an inclined part, the length of the inclined part is equal to the length of the horizontal part, and one end of the inclined part is fixedly connected with the end of the horizontal part. The other end of the inclined part is fixed with a coal scraping mechanism. The included angle between the axis of the horizontal portion and the axis of the inclined portion is 4-6°. If the angle between the axis of the horizontal part and the axis of the inclined part is greater than 6°, during the coal leveling process, as the leveling coal rod moves back and forth, it is easy to cause the coal scraping mechanism to scratch the side wall of the carbonization chamber, not only for The carboniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com