Preparation method of conductive nanocomposite material

A technology of conductive nano and composite materials, which is applied in the field of preparation of nanocomposite materials, can solve the problems of poor dispersion of nanoparticles and achieve the effects of strong structure retention, excellent mechanical properties, good continuity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific implementation mode one: the preparation method of a kind of conductive nanocomposite material of this implementation mode is specifically carried out according to the following steps:

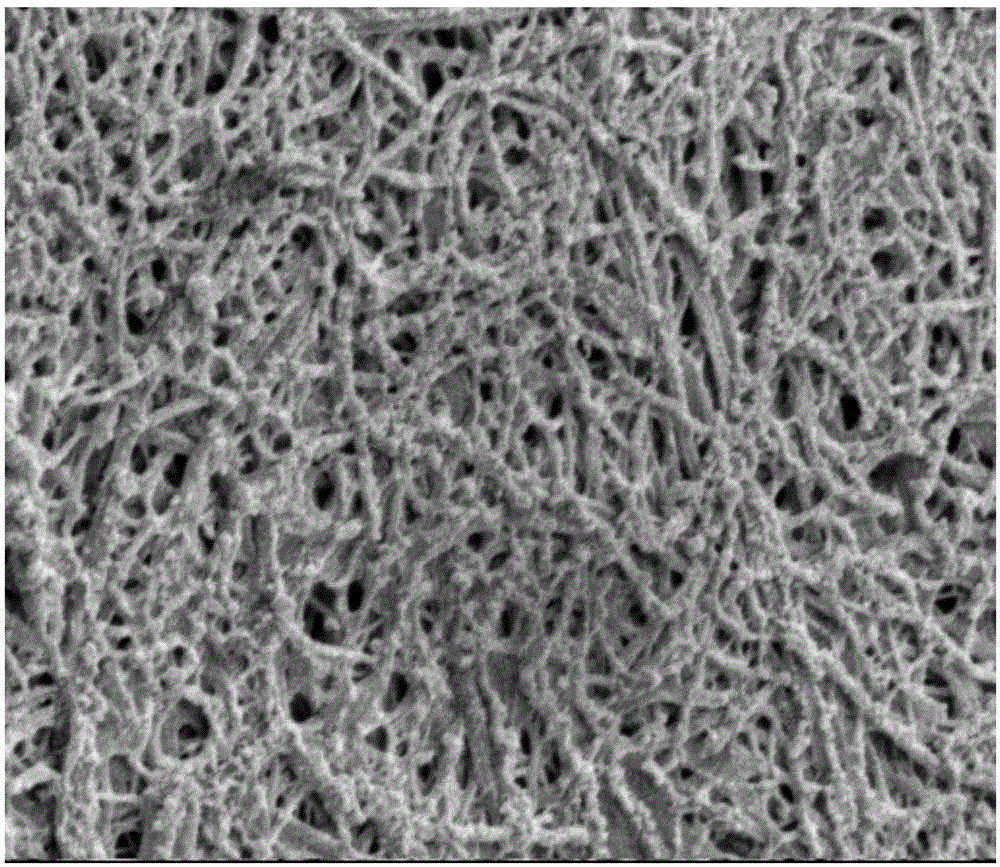

[0021] 1. Coating the polymer nanofiber dispersion to form a film, then blending and molding, and then preparing a polymer porous membrane material by etching or polymer electrospinning;

[0022] 2. Load the charged polymer onto the surface of the polymer porous membrane material prepared in step 1, control the loading amount of the charged polymer to reach a mass concentration of more than 0.15%, and then use solvent rinsing to remove the free charged polymer, blow Dry;

[0023] 3. Adsorb conductive nanoparticles to the surface of the charged polymer porous membrane material treated in step 2 by wetting, control the adsorption amount to reach a mass concentration of more than 20%, and then use solvent rinsing to remove free conductive nanoparticles Particles, blow dry; wherei...

specific Embodiment approach 2

[0026] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the preparation method of polymer nanofibers in the polymer nanofiber dispersion in step 1 is specifically carried out according to the following steps:

[0027] A. The polymer spinning stock solution with a mass concentration of 8% to 18% is used to prepare polymer primary fibers; the method for preparing polymer primary fibers is to pass the polymer spinning stock solution through a spinneret and enter a coagulation bath for solidification for 1 to 300 seconds;

[0028] B. Immerse the as-spun polymer fiber obtained in step A in the solvent in the reactor, control the temperature at 20-350° C., pressure at 1-100 atm, and ultrasonic treatment for 1-5000 h; the solvent is sulfuric acid, hydrochloric acid, methanol, ethanol, Pyridine, petroleum ether, tetrahydrofuran, carbon tetrachloride, dichloroethane, trichloroethane, dimethyl sulfoxide, triethylamine, aniline, water, phenol, ethylene glycol,...

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, the polymer nanofiber dispersion liquid is a mixed solution in which poly-p-phenylenebenzimidazole nanofibers are dispersed in ethanol / sodium hydroxide solution , wherein by mass parts poly-p-phenylenebenzimidazole nanofiber is 1 part, ethanol is 99 parts, and sodium hydroxide is 1 part. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com