Screed heating system of paver, heating method and paver

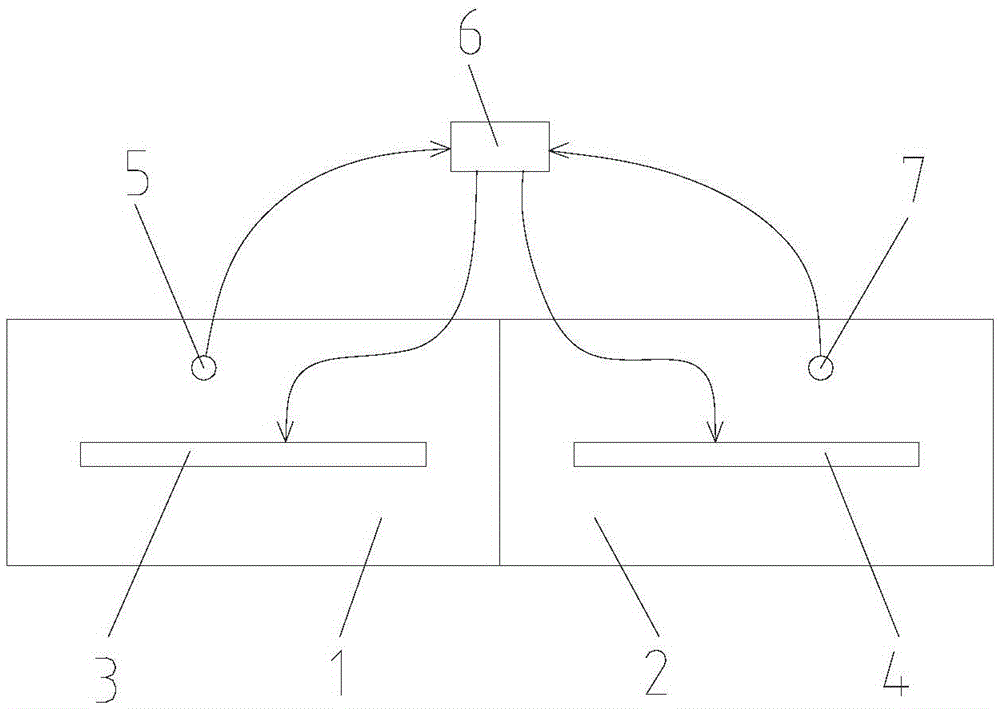

A heating system and screed technology, applied in roads, road repairs, roads, etc., can solve the problem of unreliable control of the heating temperature of sub-section screeds, and achieve the effect of precise temperature control and good paving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

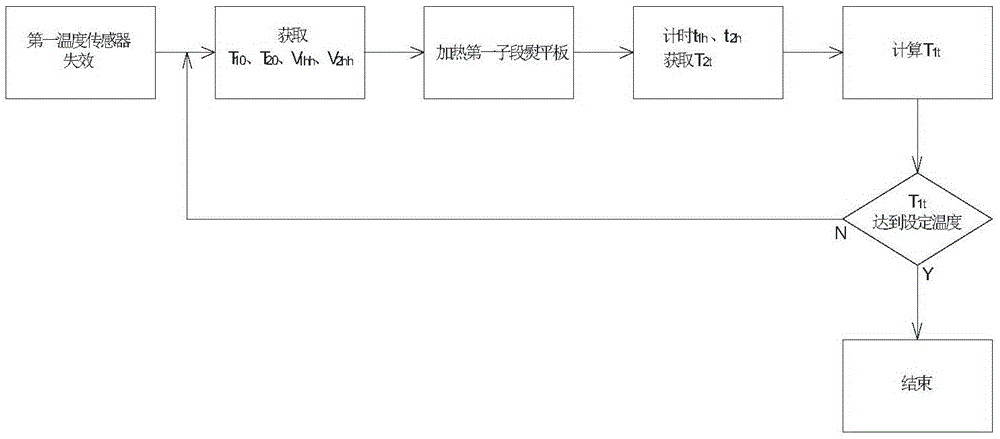

Embodiment 1

[0046] When the heating system of the screed is heated by one-time heating, when one of the temperature sensors (assumed in this embodiment, the first temperature sensor 5) fails and cannot work normally, the heating controller 6 will The temperature of screed 2 in the second subsection, the heating time of screed 1 in the first subsection and the heating time of screed 2 in the second subsection, and the historical heating speed of screed 1 in the first subsection and the screed in the second subsection 2 to calculate the nominal temperature of the screed 1 in the first subsection, and control the first heating element 3 to heat the screed 1 in the first subsection according to the nominal temperature of the screed 1 in the first subsection.

[0047] The calculation method of the nominal temperature of the first sub-section screed 1 is as follows:

[0048] T 1t =T 10 +(V 1hh ⅹV 2th / V 2hh )xt 1h ;

[0049] V 2th =(T 2t -T 20 ) / t 2h ;

[0050] Among them, T 1t Ind...

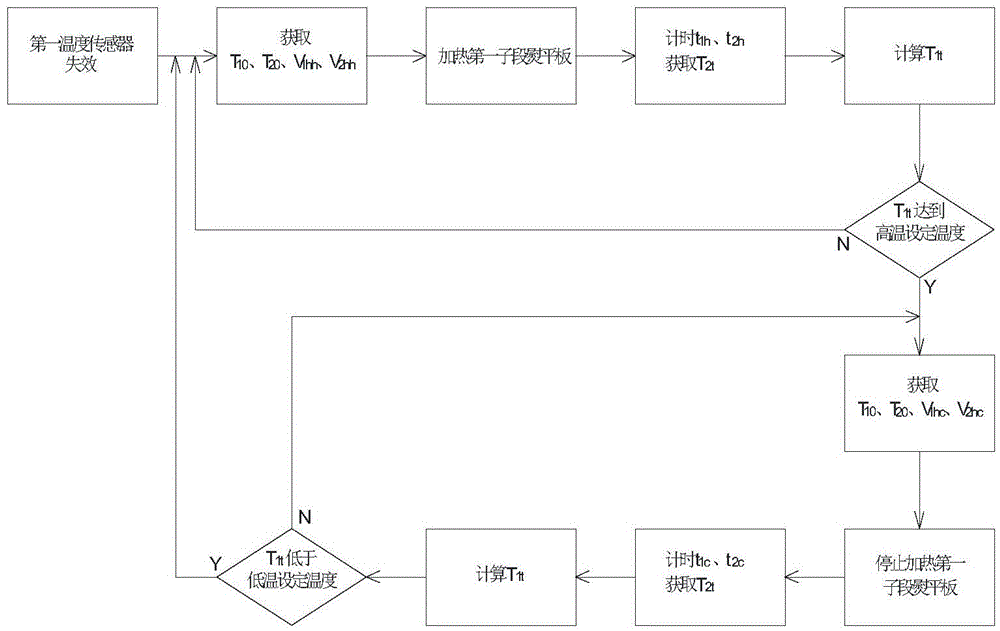

Embodiment 2

[0053] When the heating system of the screed is heated by a circulation heating method, if the first temperature sensor 5 fails during the cooling process, the heating controller 6 will also control the screeds of the first subsection 1 and the second subsection screed 2 The cooling time is counted, and the cooling rate of the first subsection screed 1 and the historical cooling rate of the second subsection screed 2 are obtained to calculate the nominal temperature of the first subsection screed 1, and according to the first subsection screed The nominal temperature of the screed 1 is used to control the heating of the first subsection screed 1 by the first heating element 3 .

[0054] The calculation method of the nominal temperature of the first sub-section screed 1 is as follows:

[0055] T 1t =T 10 +(V 1hc ⅹV 2tc / V 2hc )xt 1c ;

[0056] V 2tc =(T 2t -T 20 ) / t 2c ;

[0057] Among them, T 1t Indicates the nominal temperature of the first subsection screed 1, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com