Steel bell socket arc shearing culvert for jacking construction

A socket interface, steel technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as uneconomical investment in civil construction and pipeline installation, urban traffic congestion, etc., and achieve safe and reliable culvert quality and internal space. The effect of reducing the cost of civil construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

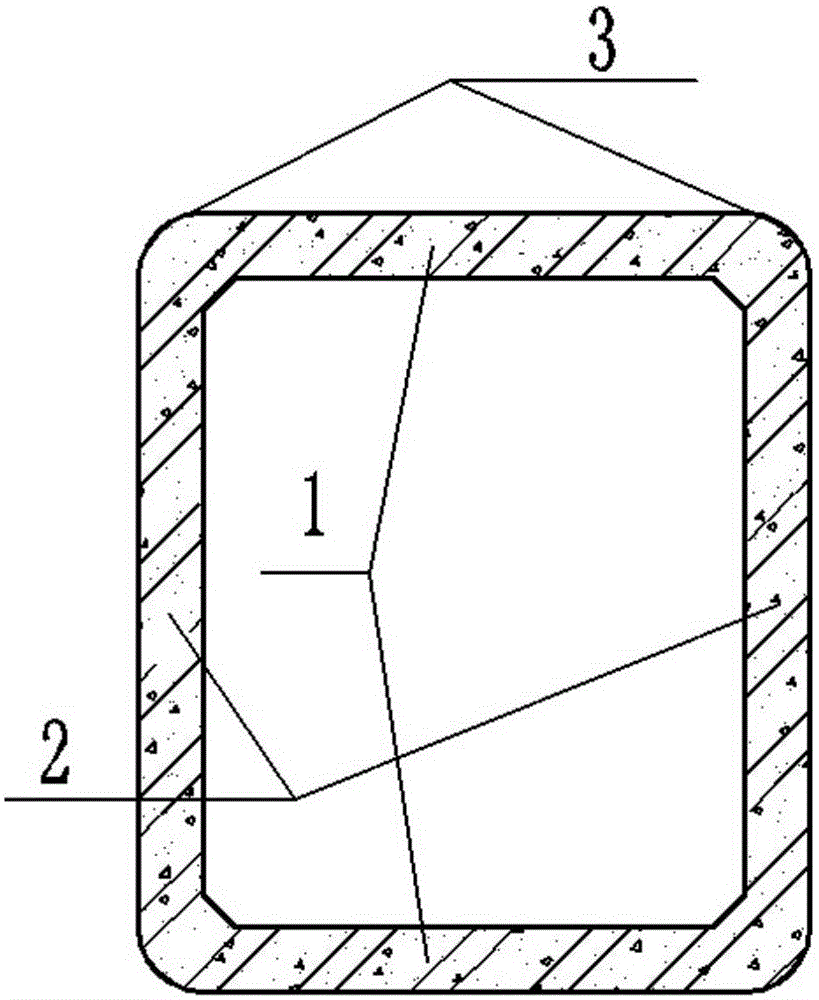

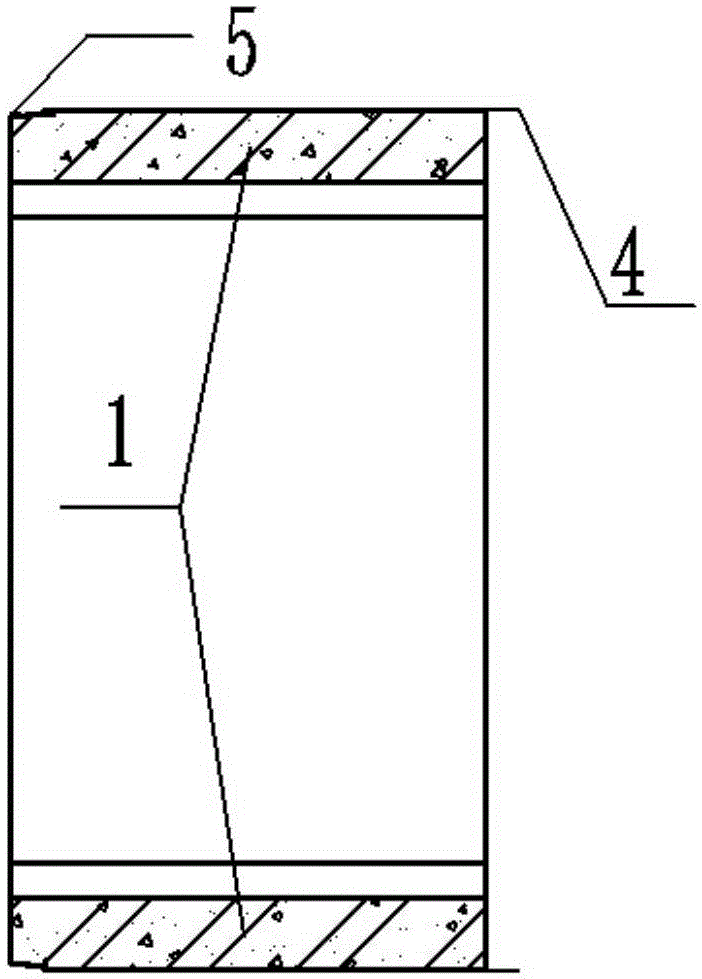

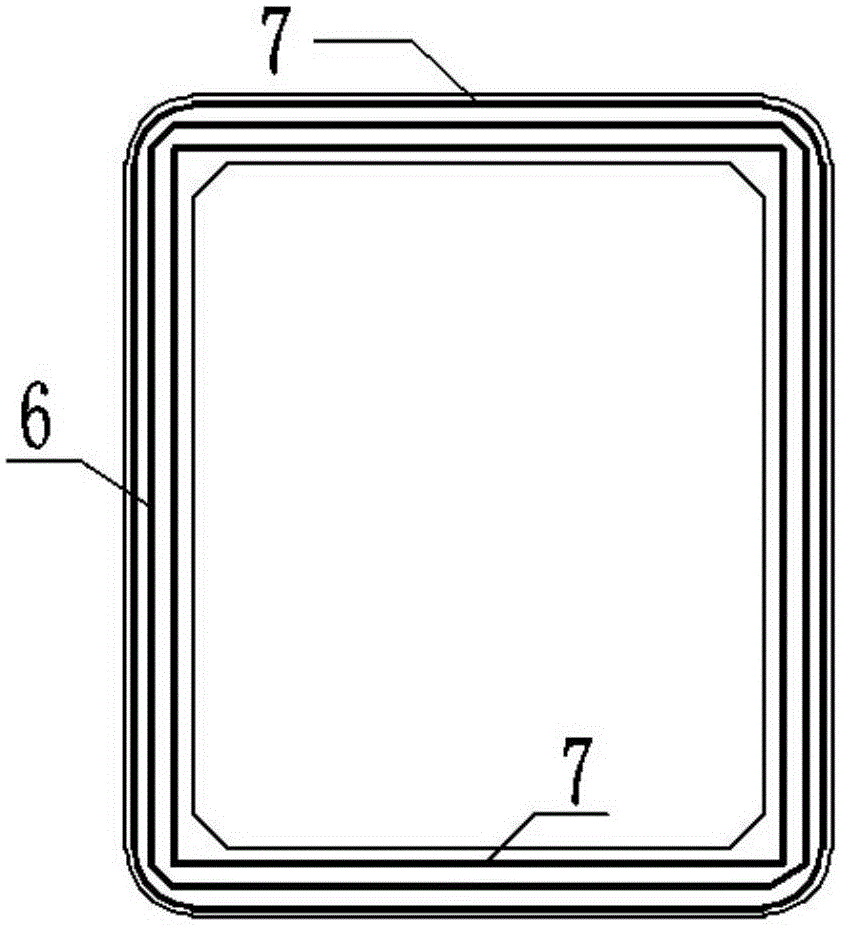

[0027] A kind of steel socket interface shear arc culvert for jacking construction, such as Figure 1 to Figure 6 As shown, it includes: top plate 1, side plate 2, arc corner 3, steel socket 4, steel socket 5, impervious steel plate 6, longitudinal reinforcement 7, apron 8, structural reinforcement in node area 9, distribution reinforcement 10 etc., where:

[0028] The top plate 1 and the side plate 2 are two pieces, which are integrally poured with high-strength concrete, the thickness of the top plate 1 is less than or equal to the thickness of the side plate 2, and the width of the top plate 1 is greater than or equal to the height of the side plate 2;

[0029] An impervious steel plate 6 is embedded in the main body of the shear arc culvert composed of the top plate 1 and the side plate 2, and the thickness of the impermeable steel plate 6 is greater than or equal to 1.5 mm;

[0030] Longitudinal bars 7 are arranged in the main body of the shear arc culvert composed of hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com