A multifunctional vibrating device

A multi-functional and equipment technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of transportation and rapid construction, the fracture of bucket teeth and knife row welds, and the inability to adapt to national defense construction, etc., to achieve convenient The effect of quick start of construction, low working noise and strong self-protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

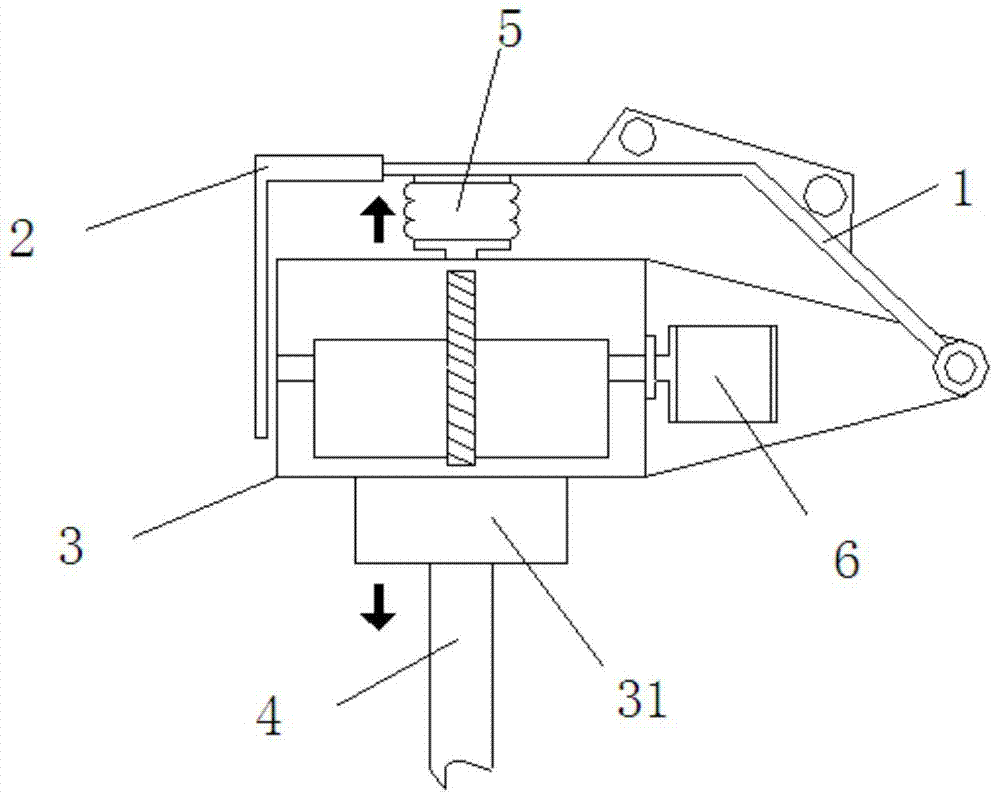

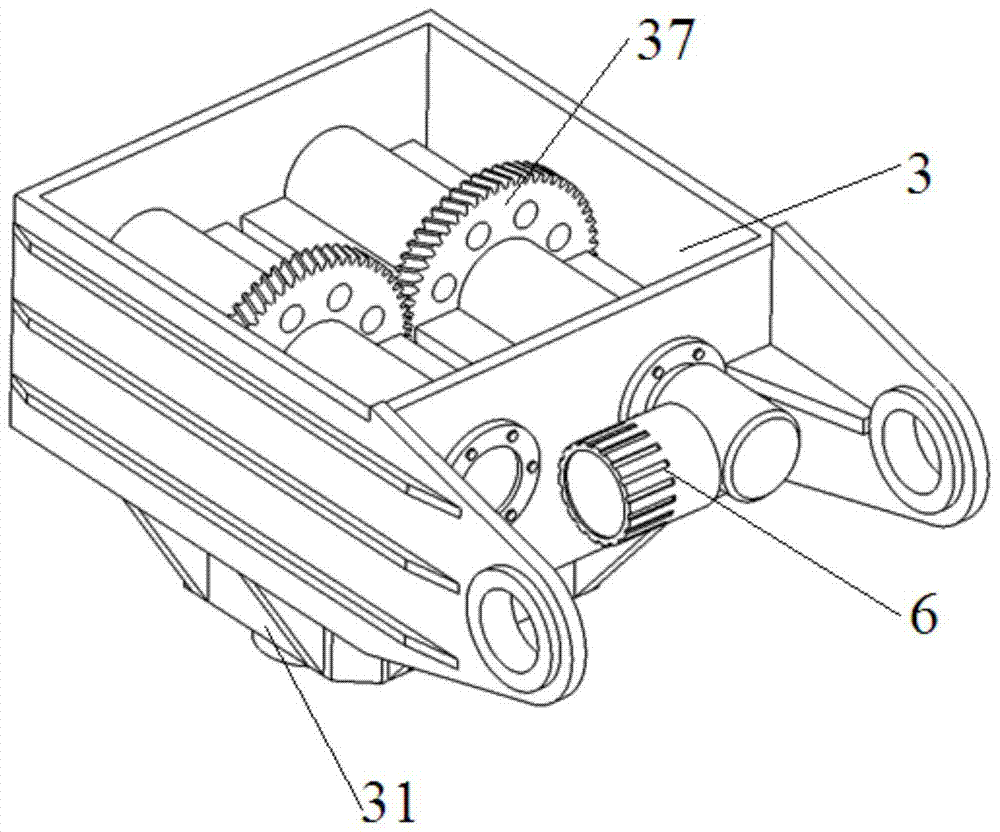

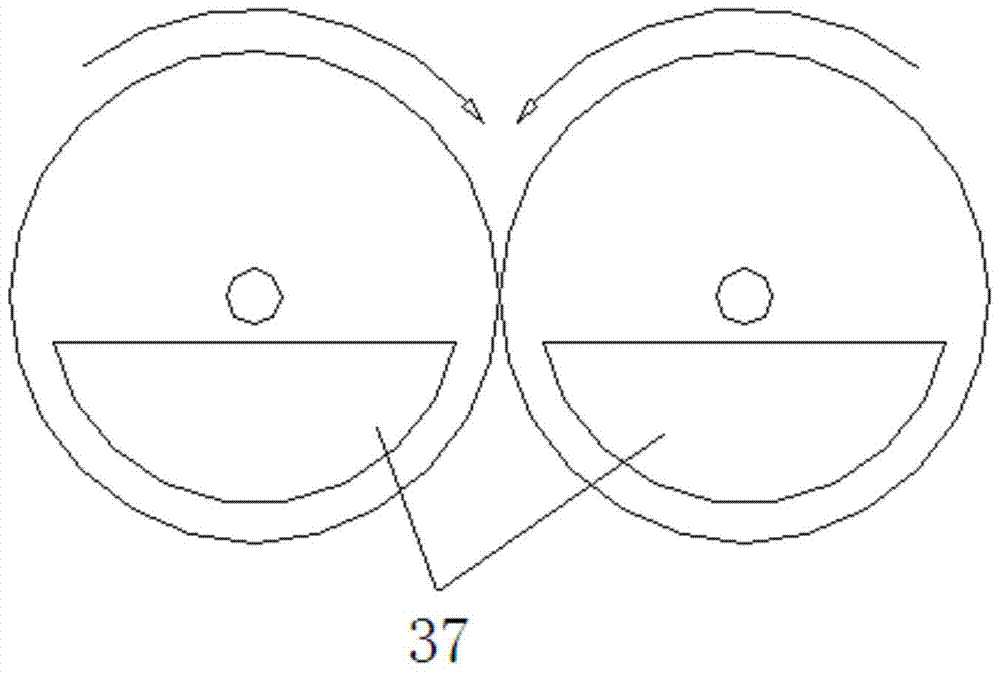

[0034] A multifunctional vibration device, such as figure 1 As shown, it includes frame 1, functional baffle 2, vibration box 3, work piece 4, nitrogen gas spring 5 and hydraulic motor 6, frame 1 covers the top of vibration box 3, and is hinged with vibration box 3, and frame 1 is used for In connection with the excavator, the nitrogen spring 5 is set between the top of the vibration box 3 and the frame 1, the work piece 4 is connected to the bottom of the vibration box 3, and the hydraulic motor 6 is connected to the side of the vibration box 3 to drive the vibration box 3 to the machine Frame 1 generates high-frequency vibration, and relies on nitrogen spring 5 for shock absorption, and the generated vibration drives work piece 4 to vibrate. The functional baffle 2 is fixedly connected to the front end of the frame 1 . This functional baffle plate 2 can also carry out work such as pavement tiling and gravel cleaning as required while protecting the normal operation of the v...

Embodiment 2

[0039] Such as Figure 7 As shown, the difference from Embodiment 1 is that in this embodiment, the work piece 4 is a flat drill rod 43, and the flat drill rod 43 can break targets such as concrete pavements or rocks.

Embodiment 3

[0041] Such as Figure 8 As shown, the difference from Embodiment 1 is that in this embodiment, the work piece 4 is a pointed drill rod 44, and the pointed drill rod 44 can break targets such as concrete pavements or rocks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com