Design Method of Shear Connectors for Steel Plate Concrete Composite Shear Wall

A technology for combining shear walls and shear connectors, applied to walls, building components, buildings, etc., can solve problems such as inability to reflect the stress state and inconsistent design methods, and achieve convenient application, prevent local buckling, and clear theoretical concepts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

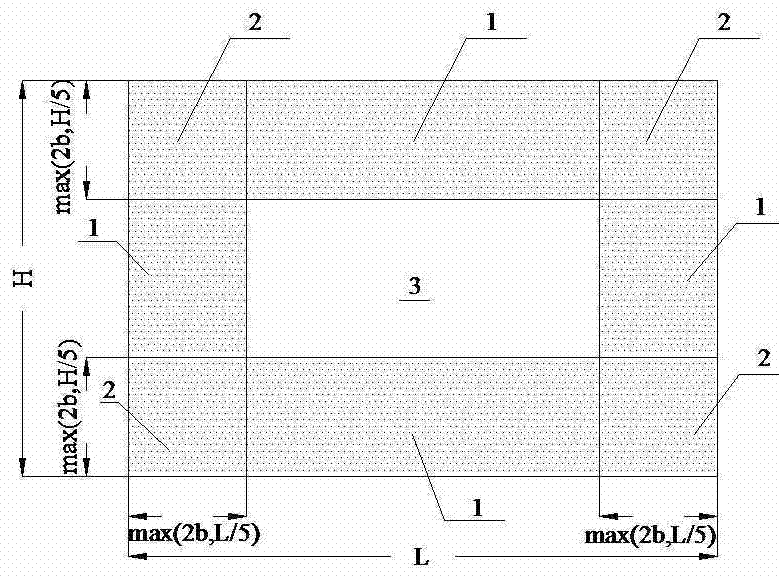

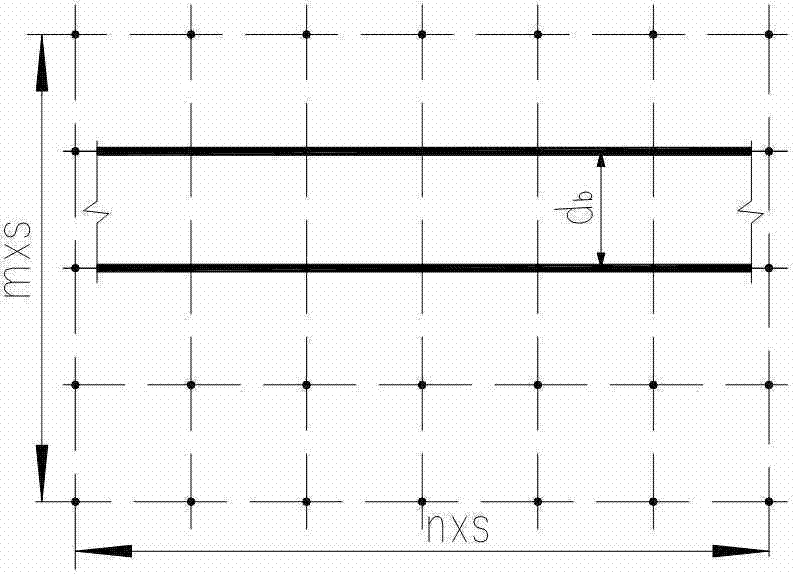

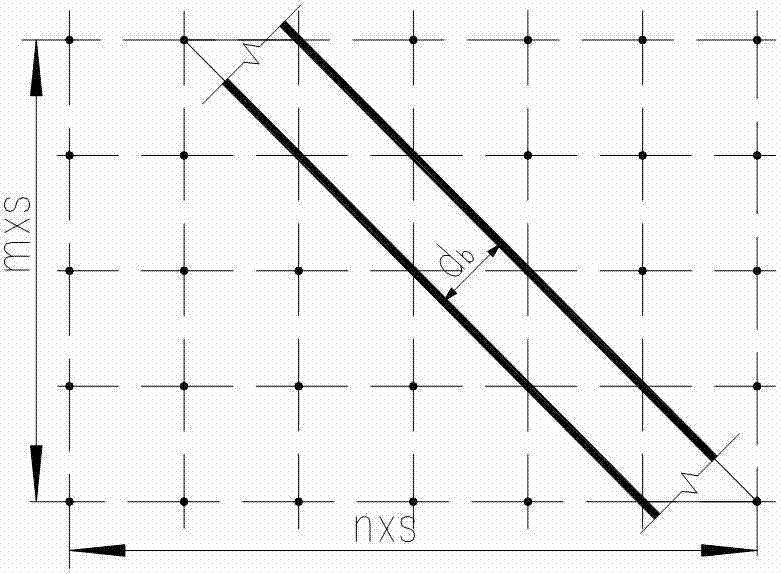

[0046] combined with figure 1 , take a certain steel plate concrete composite wall in an actual high-rise composite structure as an example to illustrate the present invention. The concrete strength grade of the wall is C60, the steel bar is HRB400, and the steel is Q345GJ steel. The wall is 13.9m long, 1.3m thick and 10.47m high. The horizontal reinforcement is 4 20@200+2 14@200, and the vertical reinforcement is 4 25@200+2 14@200. A single-layer steel plate is built in reinforced concrete with a thickness of 50mm. The connectors are studs with a diameter of 19mm. The cross-section is as large as Image 6 shown. The calculation steps are summarized in Table 2 as follows.

[0047] Table 2

[0048]

[0049] The calculation results in Table 2 take into account the structural requirements of JGJ3-2010 and GB50017-2003 not greater than 300mm and not less than 6 times the stud diameter, the final value of the stud spacing see the values in parentheses.

[0050] From th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com