Special tool for deep water test depth correction

A special tool and depth calibration technology, applied in the field of deep water testing tools, can solve the problems of pipe string safety risk, large depth calibration error, large depth error, etc., and achieve the effect of reducing risks and accidents, avoiding large errors and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

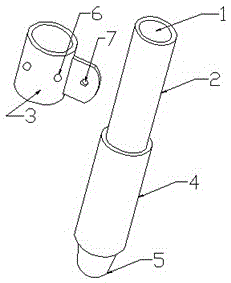

[0013] Such as figure 1 As shown, a special tool for deep water testing and depth correction described in this embodiment includes an upper airtight buckle 1 for connecting the upper pipe string of the puppet, an upper puppet body 2, an integral lifting lug 3, and a lower thickening short The joint body 4 and the lower gas-tight buckle 5 used to connect the lower pipe string of the nipple, the upper nipple body 2 and the lower thickened nipple body 4 are an integrated structure, and the integral lifting lug 3 is set on the upper nipple The joint body 2 is locked by the top screw 6, the upper airtight buckle 1 and the lower airtight buckle 5 are used to connect the upper and lower pipe strings of the pup joint, and play a sealing role.

[0014] Wherein, in this embodiment, the inner diameter of the upper sub-section body 2 and the lower thickened sub-section body 4 are the same, the outer diameter of the lower thickened sub-joint body 4 is larger than the outer diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com