Three-dimensional scanning vibration control parametric design method for existing pump room cluster power equipment

A parametric design and vibration control technology, applied in computing, electrical and digital data processing, special data processing applications, etc., can solve the problems of wasting time and labor costs, incomplete design information, and large field spans, to speed up the progress of the project. , Accurate reproduction of parameters, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

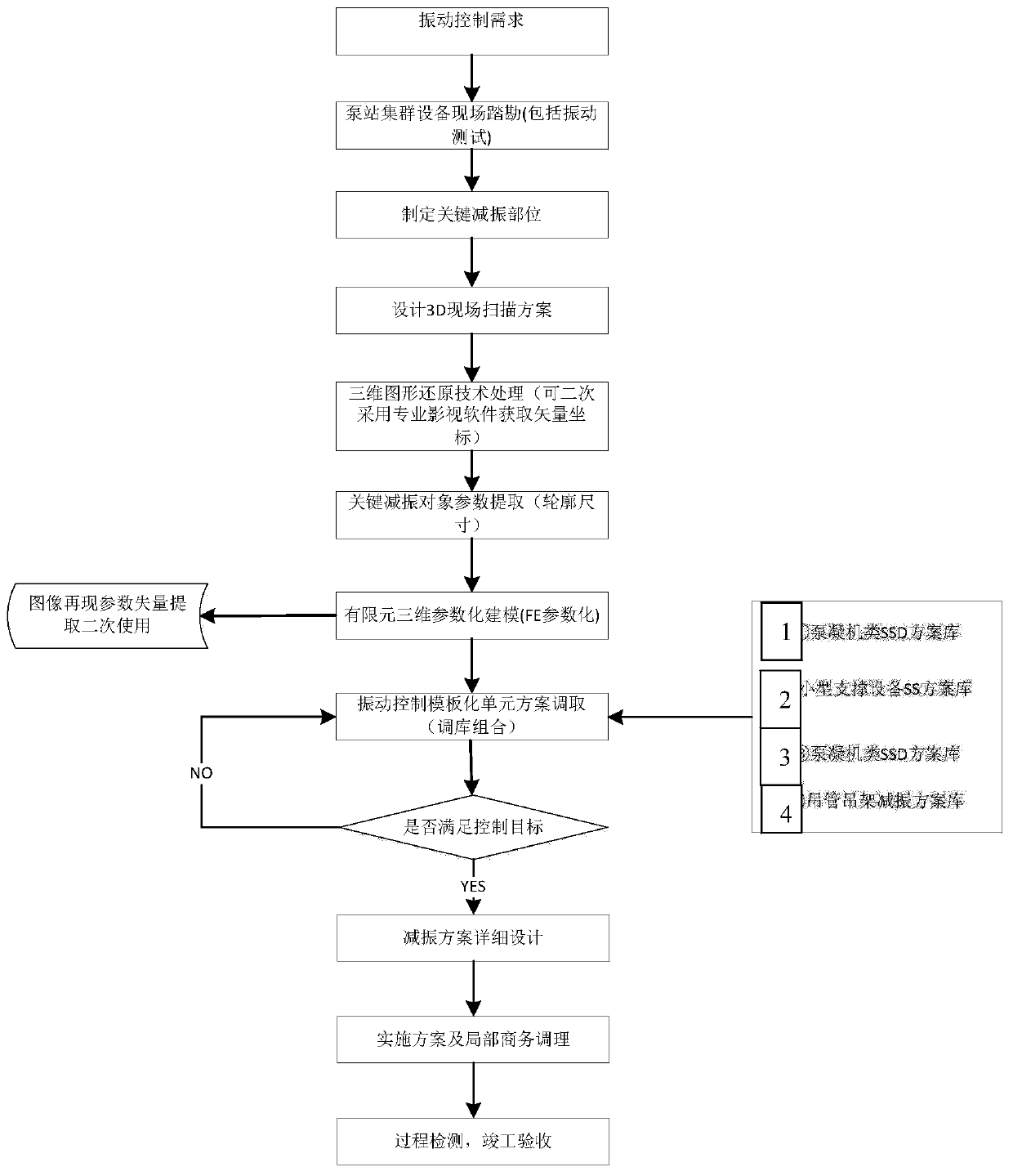

[0031] see figure 1 , a flow chart of a parametric design method for three-dimensional scanning vibration control of existing pump room cluster power equipment, including:

[0032] First put forward the vibration control requirements, and then implement the following steps:

[0033] Step 1. Preliminary data collection: According to the requirements of vibration control technology, conduct field surveys and vibration tests on the pumping station cluster equipment, formulate key vibration reduction parts and obtain data information on key vibration reduction parts;

[0034] Step 2: Design a 3D on-site scanning solution: set up multiple stations, conduct all-round 3D scanning for multiple damping parts, and continuously and automatically collect location information of spatial points and other point source information;

[0035] Step 3: Restoring the three-dimensional graphics: integrating the acquired location information of the spatial points and other point source information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com