Water turbine fault prognosis method based on on-line monitoring

A technology of fault diagnosis and water turbine, which is applied in the fields of hydroelectric power generation, mechanical equipment, engine components, etc. It can solve the problems that traditional diagnosis methods cannot carry out online diagnosis, and achieve the effect of rich content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

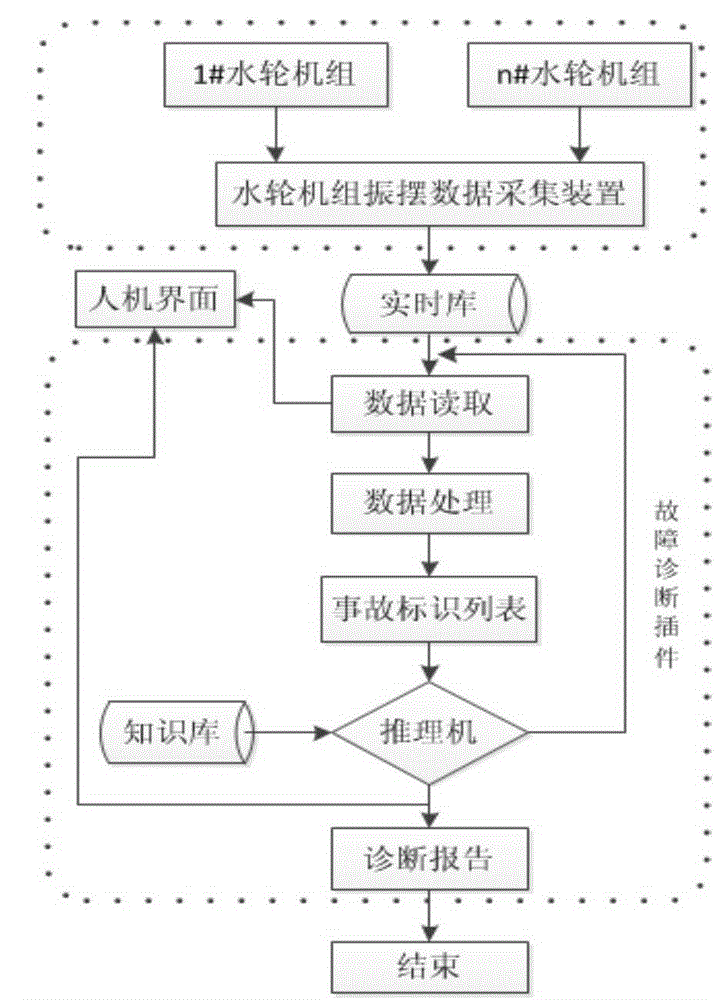

[0021] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings. figure 1 Shown is the diagnosis data collection and diagnosis flow chart.

[0022] Step 1. According to the needs of on-site application services, the vibration sample data of each monitoring channel of the hydro-generator set can be collected through the vibration monitoring device, and then the sample data generated by the vibration device can be obtained through a dedicated device and a customized driver, so as to realize various The sample data of the vibration channel is connected to the real-time database, mainly: the vibration value and amplitude of the upper frame of the turbine in the X and Y directions, the swing value and amplitude of the upper guide in the X and Y directions, and the swing of the water guide in the X and Y directions Value and amplitude; and collect other relevant data: speed, unit load, unit load rejection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com