Mud turbine generator of automatic vertical drilling tool

A vertical drilling and mud turbine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems that affect the drilling efficiency of vertical drilling tools, limited battery power supply, low power supply efficiency, etc., to ensure operational timeliness , low cost, and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

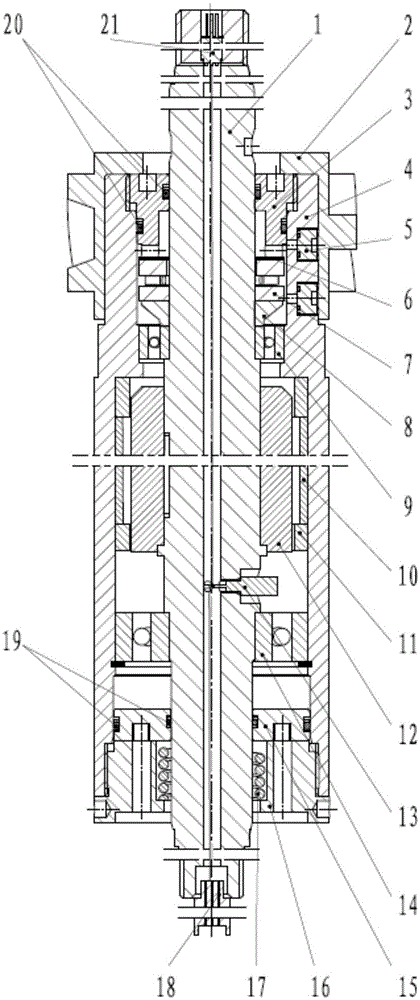

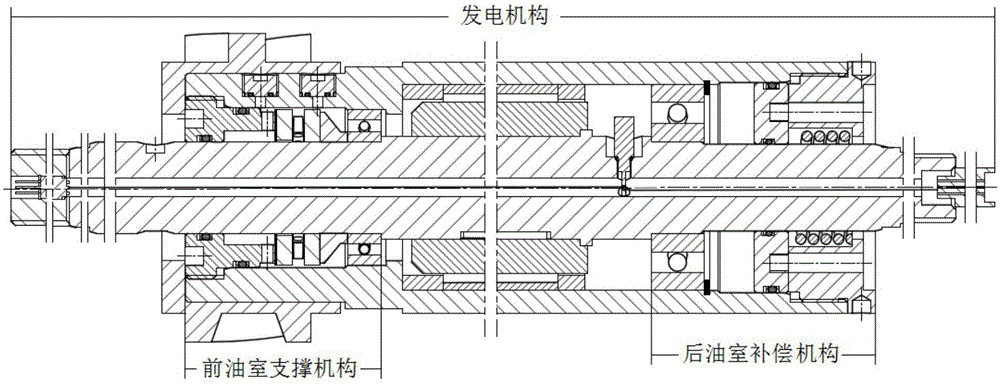

[0017] refer to figure 1 , the structure of the present invention is to include three parts: power generation mechanism, front oil chamber support mechanism and rear oil chamber compensation mechanism,

[0018] The structure of the generating mechanism is that an inner permanent magnet 12 is set on the outer circle of the middle part of the motor shaft 1 to form a generator stator; a magnet fixing frame 11 is set on the inner permanent magnet 12, and an outer permanent magnet 10 is fixed on the magnet fixing frame 11. , the external permanent magnet 10 is covered with the motor outer cylinder 4, and the outer circle of the motor outer cylinder 4 is fastened with the turbine 2 to form the generator rotor; the upper and lower ends of the motor shaft 1 are respectively equipped with four-core high-pressure seals 21 and multiple The core high-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com