Compressor

A technology of a compressor and a compression mechanism, applied in the field of compressors, can solve the problems affecting the energy efficiency and high power of the compressor, and achieve the effects of improving adaptability, improving performance, improving heating capacity and energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

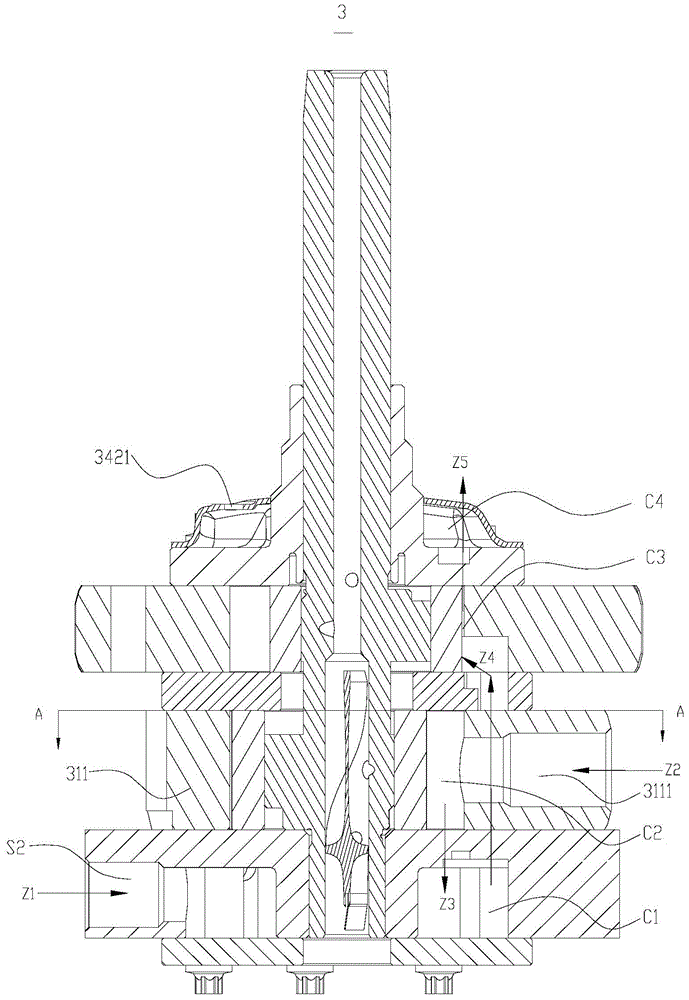

[0087] refer to Figure 4 and Figure 5 The injection port S5 is formed on the first cylinder 311, and an injection channel S4 communicating with the injection port S5 is further formed on the first cylinder 311, and the injection valve 6 is a valve assembly arranged on the injection channel S4. refer to image 3 , the injection channel S4 can penetrate the first cylinder 311 along the radial direction of the first cylinder 311, and the outer end of the injection channel S4 penetrates the outer peripheral surface of the first cylinder 311, and the inner end of the injection channel S4 penetrates to the first compression chamber C2, the valve The assembly may include an injection valve seat, a lift limiter 61 and a one-way valve plate 62 installed on the injection valve seat, wherein a perforation that does not block the injection channel S4 is formed on the injection valve seat, and the lift limiter 61 It can be fixed on the side of the injection valve seat adjacent to the f...

Embodiment 2

[0091] The injection port S5 is formed on the diaphragm assembly 35 and / or the first bearing assembly 33, the injection port S5 is configured to be opened and closed by the first piston 314 during the rotation of the first piston 314, and the injection valve 6 is the first piston 314. That is to say, the injection port S5 can be opened or closed during the rolling process of the first piston 314 to realize injection or blocking of the second-pressure refrigerant.

[0092] For example in Image 6In an example, the injection port S5 may be formed on the baffle assembly 35 (and / or the first bearing assembly 33) and communicate with the first compression on the first cylinder 311, the baffle assembly 35 (and / or the first bearing assembly 33) is further formed with an injection channel S4, one end of the injection channel S4 communicates with the injection port S5, and the other end of the injection channel S4 penetrates the outer peripheral surface of the partition plate assembly...

Embodiment 3

[0095] refer to Image 6 The baffle assembly 35 and / or the first bearing assembly 33 are formed with the injection port S5 and the injection channel S4 communicating with the injection port S5, that is to say, the injection port S5 and the injection channel S4 can both be formed on the baffle assembly 35 , the injection port S5 and the injection channel S4 can also be formed on the first bearing assembly 33, the injection port S5 and the injection channel S4 can also be formed on the separator assembly 35 and both are formed on the first bearing assembly 33 at the same time, the injection The valve 6 includes a valve assembly arranged on the injection channel S4, wherein the valve assembly is the same as the valve assembly in the first embodiment above, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com