High temperature T-type damper

A high-temperature, damper technology, applied in multi-port valves, valve devices, engine components, etc., can solve the problems of troublesome valve body insulation, overheating of the actuator, and difficulty in fully opening the valve plate, avoiding metal contact heat conduction, ensuring Stability of work, effect of reducing heat conduction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

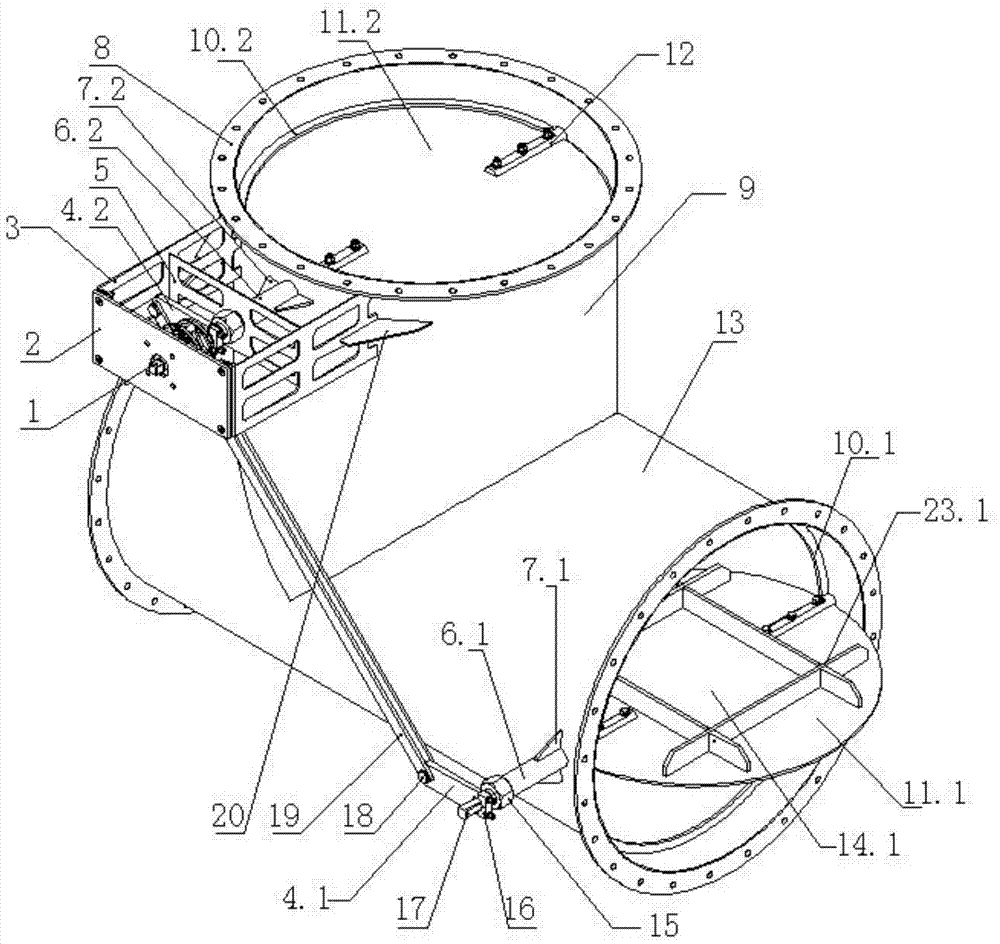

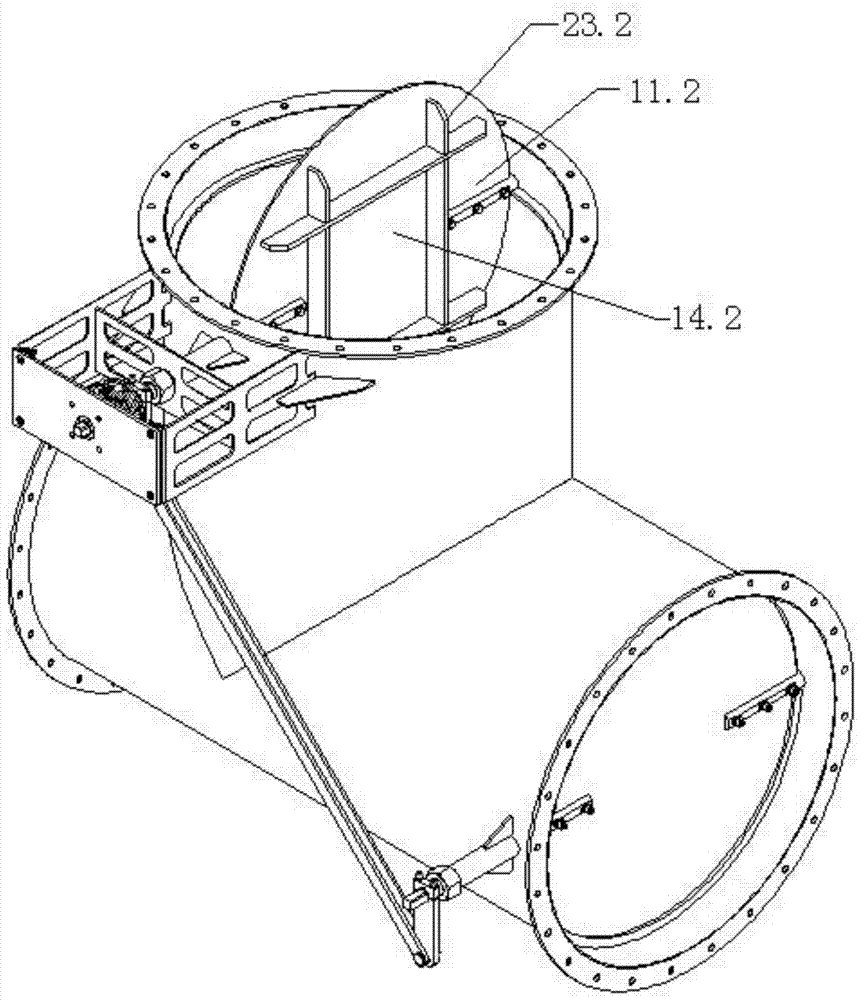

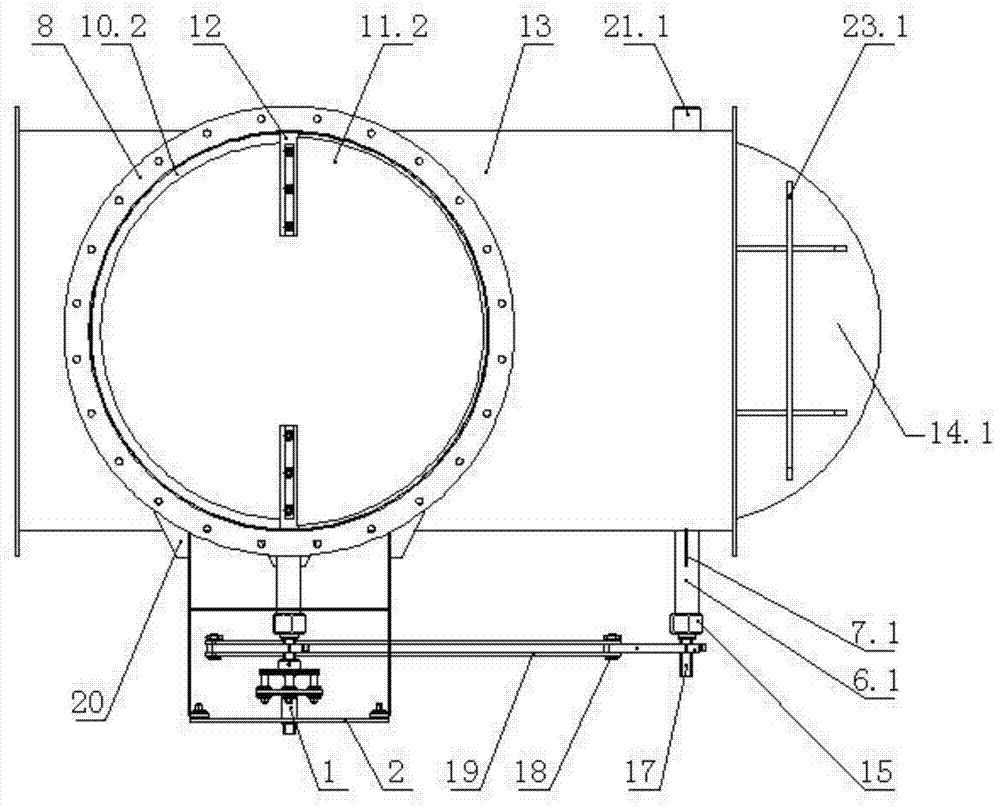

[0021] Attached below Figure 1-6 The present invention is described further:

[0022] The high-temperature T-type air valve includes a horizontal valve body 13 and a vertical valve body 9 connected in a T-shape, flanges 8 are connected to both ends of the horizontal valve body 13 and the upper end of the vertical valve body 9, and the bracket 3 passes through the positioning plate 20 Fixedly connected to the outer wall of the vertical valve body 9, the bracket fixing plate 5 is installed in the bracket 3, and the countersunk screw 25 passes through the actuator fixing plate 2, the heat-insulating mica ring b24.2 fixed in the bracket 3 and the bracket 3 The heat-insulating mica pads 22.2 on both sides make the actuator fixed plate 2 and the support 3 fixed and heat-insulated, and the heat-insulating transmission mechanism 1 is located in the support 3;

[0023] The heat-insulating transmission mechanism 1 includes a main shaft connection sleeve 26, the main shaft connection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com