Hose connection flange

A hose connection and flange technology, which is used in hose connection devices, flange connections, pipes/pipe joints/fittings, etc., can solve problems such as high cost, inability to solve long-term sealing, and long welding cycle for pipe joint connections. , to achieve the effect of long-term sealing, convenient operation and maintenance, and saving construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

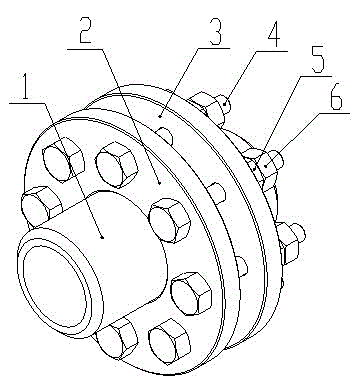

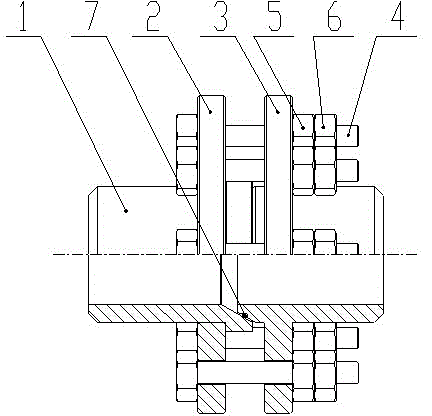

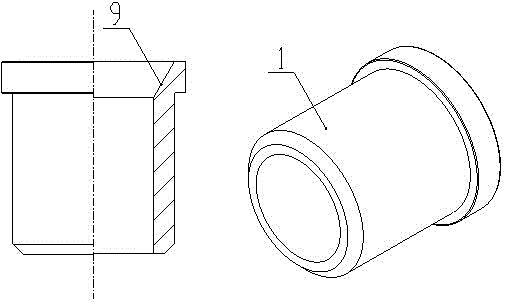

[0017] Such as Figure 1-4 As shown, the hose connection flange includes a butt seal head 1, a flange pressure plate 2, a flange body 3, and a seal ring 7. The butt seal head 1 and the flange pressure plate 2 fit together, and the butt seal head 1 and the flange body 3 The cooperation between the conical surface groove 8 and the sealing inner conical surface 9 is realized, and the sealing ring 7 is arranged between the butt joint sealing head 1 and the conical surface structure of the flange body 3, and the sealing ring 7 is continuously compressed through the locking action of the locking mechanism. Sealing ring 7 realizes sealing, and sealing ring 7 is a metal sealing ring, and its texture is softer than the cone structure.

[0018] The hose connection flange installation process is as follows:

[0019] 1. Weld the flange body 3 and the hose joint; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com