Insertion sealing equipment and use method

A technology for inserting seals and equipment, which is applied in drilling equipment, sealing/package, earthwork drilling and production, etc. It can solve the problems of reduced sealing effect, difficult operability, and failure of pipe strings, so as to reduce processing technology requirements and improve reliability. Improvement of operability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

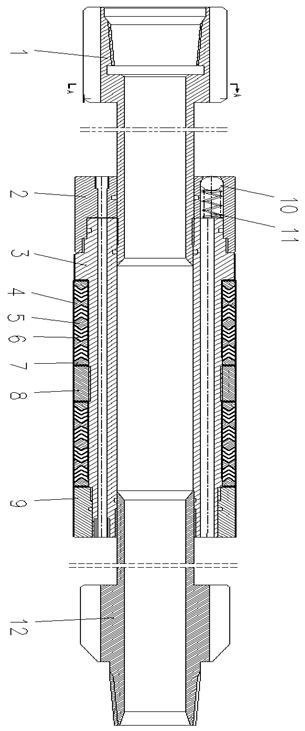

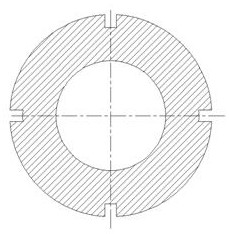

[0042] see Figure 1 to Figure 2 , the present invention provides a technical solution:

[0043] An insertion sealing device, comprising a sealing seat 3 and a sealing mechanism, the center of the sealing seat is provided with an axial through hole, and the sealing mechanism is set on the outer wall of the sealing seat;

[0044] The sealing mechanism includes an upper sealing unit, a lower sealing unit, and an adjustment ring 8 that are all set on the outside of the sealing seat; the upper sealing unit and the lower sealing unit have the same structure and are arranged symmetrically;

[0045] The inner wall of the adjusting ring is connected with the outer wall of the sealing seat by thread; the upper end surface of the adjusting ring is in contact with the bottom of the upper sealing unit, and the lower end surface of the adjusting ring is in contact with the lower sealing unit;

[0046] The upper sealing unit or the lower sealing unit includes a concave spacer ring 4, a con...

Embodiment 2

[0065] see Figure 1 to Figure 2 , the present invention provides a technical solution:

[0066] An insertion sealing device, comprising a sealing seat 3 and a sealing mechanism, the center of the sealing seat is provided with an axial through hole, and the sealing mechanism is set on the outer wall of the sealing seat;

[0067] The sealing mechanism includes an upper sealing unit, a lower sealing unit, and an adjustment ring 8 that are all set on the outside of the sealing seat; the upper sealing unit and the lower sealing unit have the same structure and are arranged symmetrically;

[0068] The inner wall of the adjusting ring is connected with the outer wall of the sealing seat by thread; the upper end surface of the adjusting ring is in contact with the bottom of the upper sealing unit, and the lower end surface of the adjusting ring is in contact with the lower sealing unit;

[0069] The upper sealing unit or the lower sealing unit includes a concave spacer ring 4, a con...

Embodiment 3

[0076] see Figure 1 to Figure 2 , the present invention provides a technical solution:

[0077] An insertion sealing device, comprising a sealing seat 3 and a sealing mechanism, the center of the sealing seat is provided with an axial through hole, and the sealing mechanism is set on the outer wall of the sealing seat;

[0078] The sealing mechanism includes an upper sealing unit, a lower sealing unit, and an adjustment ring 8 that are all set on the outside of the sealing seat; the upper sealing unit and the lower sealing unit have the same structure and are arranged symmetrically;

[0079] The inner wall of the adjusting ring is connected with the outer wall of the sealing seat by thread; the upper end surface of the adjusting ring is in contact with the bottom of the upper sealing unit, and the lower end surface of the adjusting ring is in contact with the lower sealing unit;

[0080]The upper sealing unit or the lower sealing unit includes a concave spacer ring 4, a conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com