Compensable rocker arm sealing device

A sealing device and compensation technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of no compensation for the sealing direction of the sealing strip, expansion and aging of the sealing strip and the sealing frame, so as to improve the sealing effect and reduce the Effects of friction loss and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

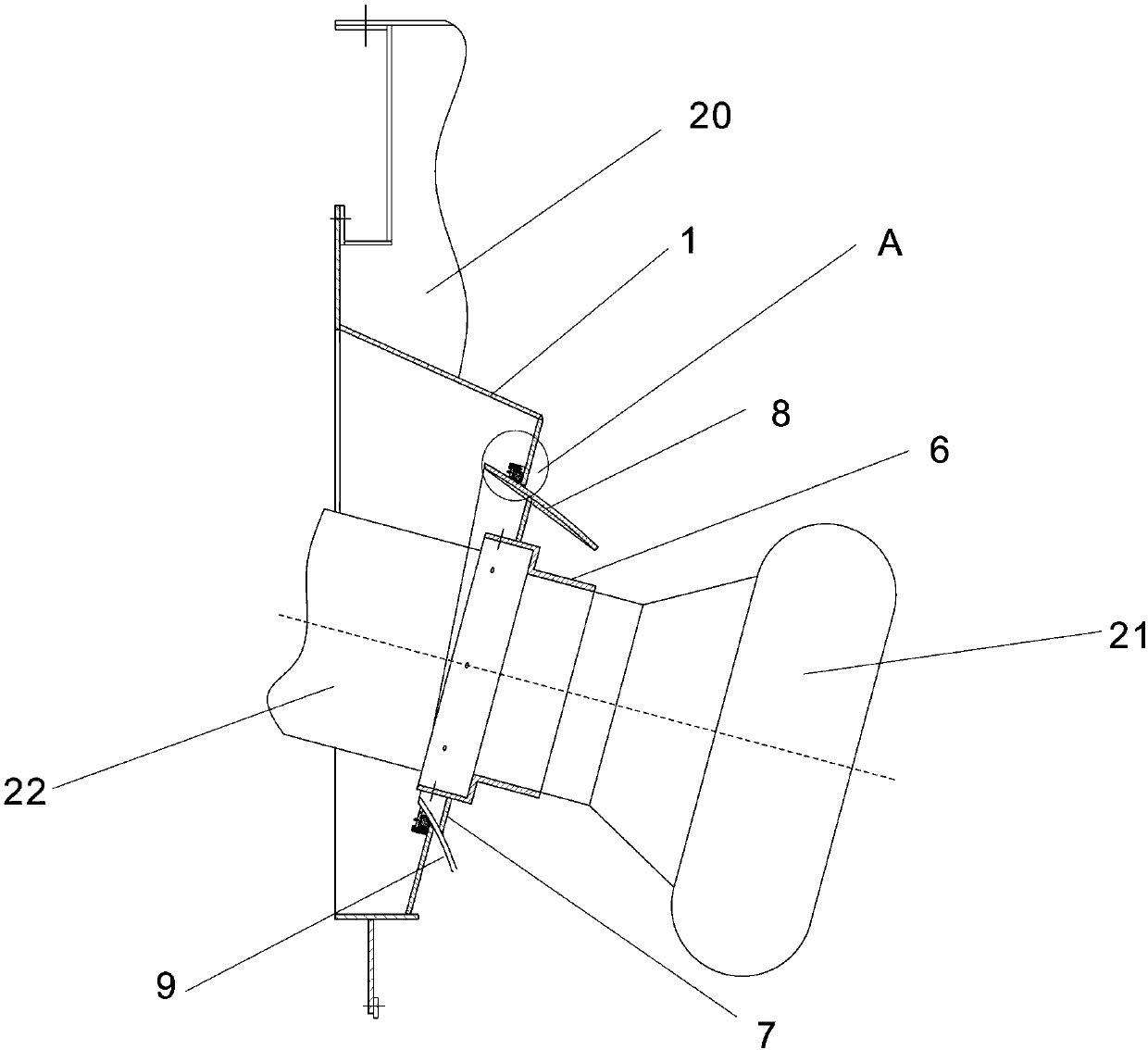

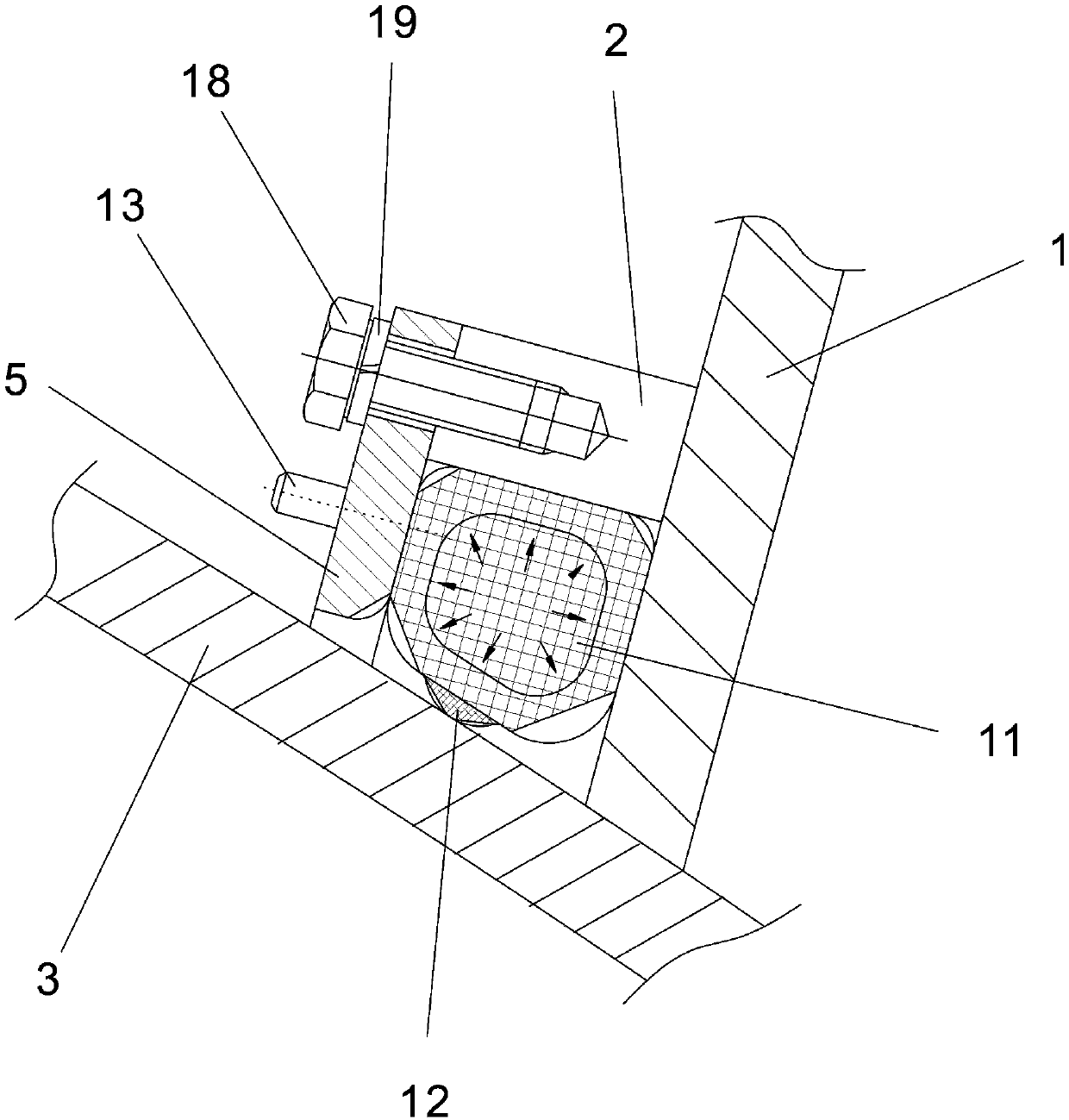

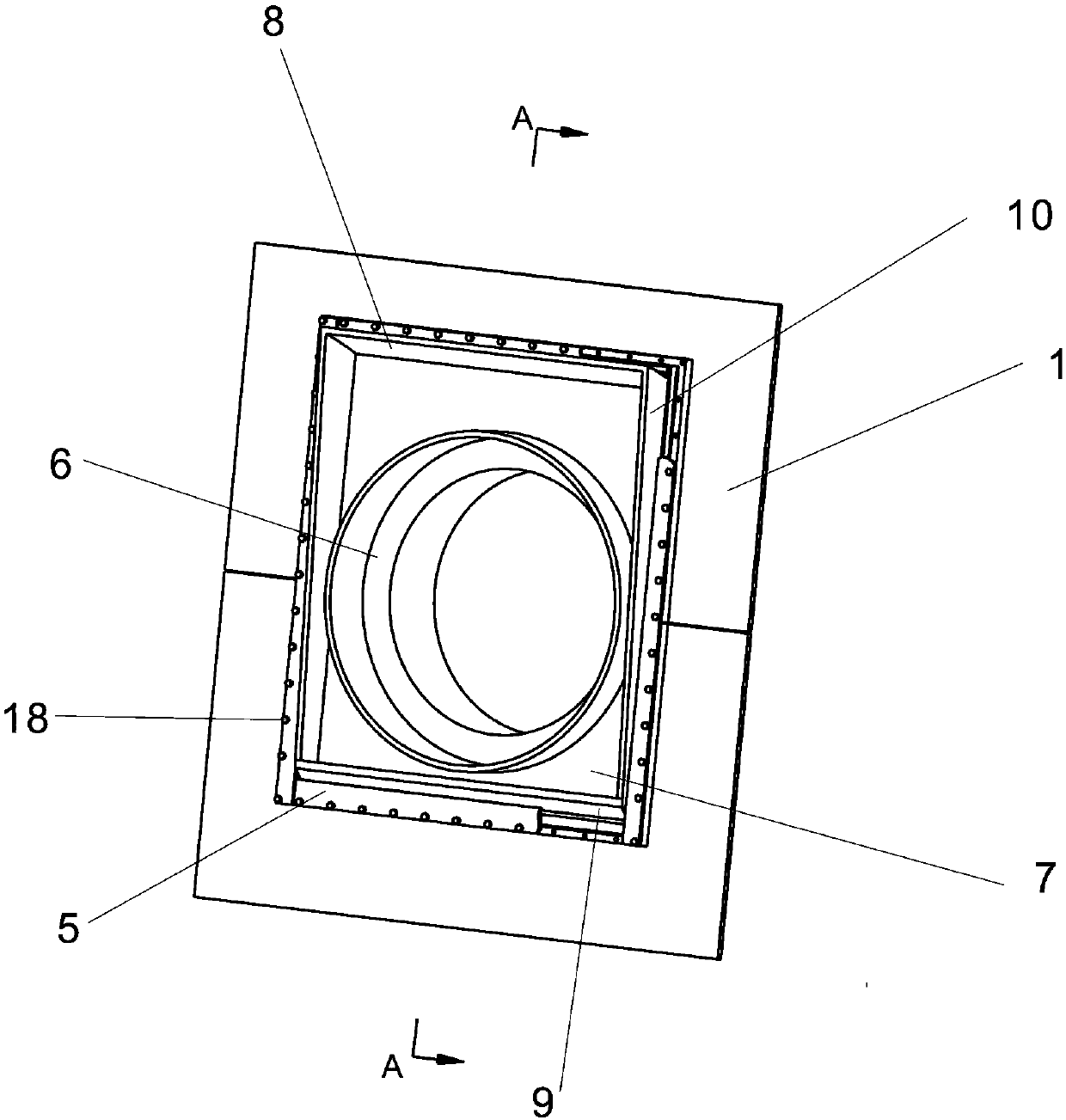

[0049] Embodiment 1 of the present invention discloses a compensable rocker arm sealing device, which is installed on the middle casing 20, and a rocker arm 21 and a grinding roller 22 are installed inside, and the rocker arm 21 is driven by the rocker arm shaft (not shown), including Grinding roller door 1, sealing seat 2, sealing frame 3, sealing air bag 4 and pressure plate 5;

[0050] The center of the grinding roller door 1 is provided with a cavity structure, the grinding roller door 1 is connected to the middle shell 20, and one side of the grinding roller door 1 protrudes outward from the ring-shaped sealing seat 2;

[0051] The sealing seat 2 is arranged concentrically with the cavity;

[0052] The sealing frame 3 is inserted into the cavity structure, and is in contact with the grinding roller door 1, and the sealing frame 3 is inserted with a rocker arm 21 and a grinding roller 22;

[0053] A sealing air bag 4 is installed between the roller door 1, the sealing sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com