Construction method for fireproof material of throat part of grate cooler

A technology of refractory materials and construction methods, applied in the direction of lining repair, etc., can solve the problem of increasing the service life of refractory materials in the throat of grate coolers, and achieve the effects of small engineering volume, simple technology, and reduced damage speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

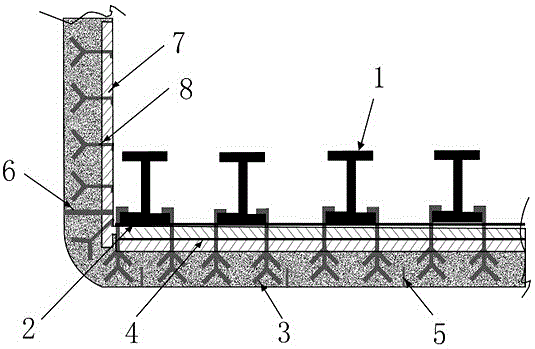

[0023] Example 1, such as figure 1 , 2 Shown, a kind of grate cooler throat refractory construction method is characterized in that: it comprises the following steps to complete; steel structure installation → Anchor installation → Calcium silicate board installation → Treatment of the interface between old and new castables → Formwork and expansion joints → pouring → Formwork removal and maintenance;

[0024] Said steel structure installation:

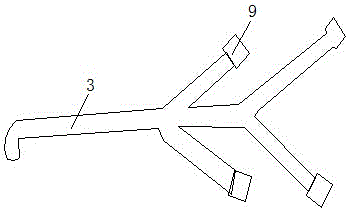

[0025] The steel structure includes: shaped steel 1, steel plate 2, first anchor 3, double-layer calcium silicate board 4, expansion joint plate 5, brick support plate 6, second anchor 7, and single-layer calcium silicate board 8.

[0026] Lateral Grate Cooler Throat

[0027] The top of the throat of the horizontal grate cooler adopts H250 type steel 1 with a spacing of about 450mm to ensure that the spacing between anchor pieces is 250mm; the lower part of the steel plate 1 is fully welded with 8-12mm thick steel plates 2; S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com