Gas Specific Heat Capacity Ratio Measuring Method and System

A technology of specific heat capacity ratio and measurement method, applied in the field of measurement, can solve the problems of inability to correct the influence of temperature and humidity environment, difficult simultaneous measurement of pressure and volume, low experimental measurement accuracy, etc., so as to reduce instrument cost, improve compliance, and improve experimental The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

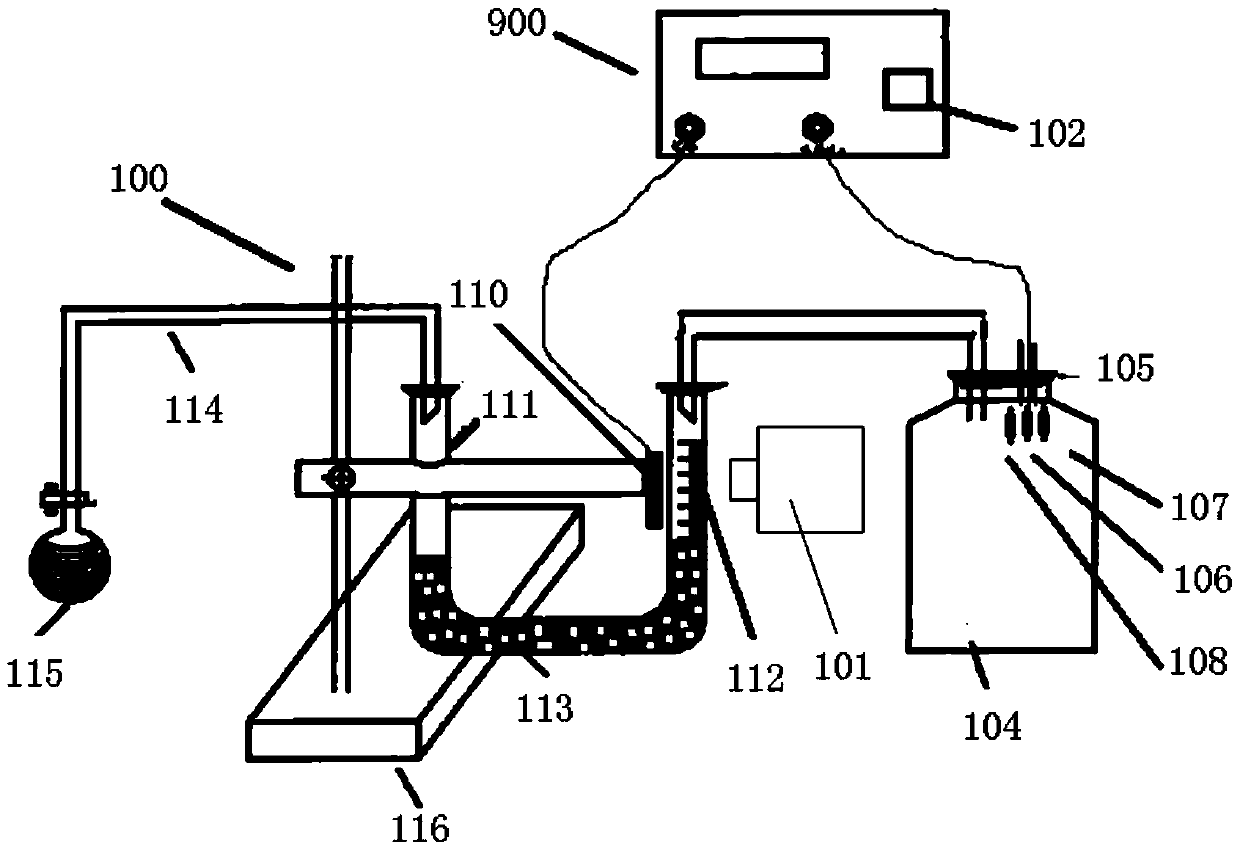

[0041] figure 1 Shown is a structural schematic diagram of an embodiment of a gas specific heat capacity ratio measurement system of the present invention. The gas specific heat capacity ratio measuring system comprises: a gas specific heat capacity ratio measuring device (100), a controller (900); the gas specific heat capacity ratio measuring device (100) includes a barometer (102), a flask (104), a flask stopper ( 105), differential pressure gauge (106), U-shaped tube (111), scale (112), water column (113), glass thin tube (114), air bag (115), support (116); wherein, U-shaped tube Be equal-diameter (R=1.598cm) cylindrical U-shaped tube, water column (113) is the non-transparent liquid that tap water and dyestuff mix, and air bag (115) is the hand-held inflatable ball that has deflation valve, and flask (104) is gas Glass flask (effective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com