LCD panel and LCD module

A liquid crystal display panel and backlight module technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of low bonding reliability, increase bonding reliability, increase bonding area, and solve relative displacement Even the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

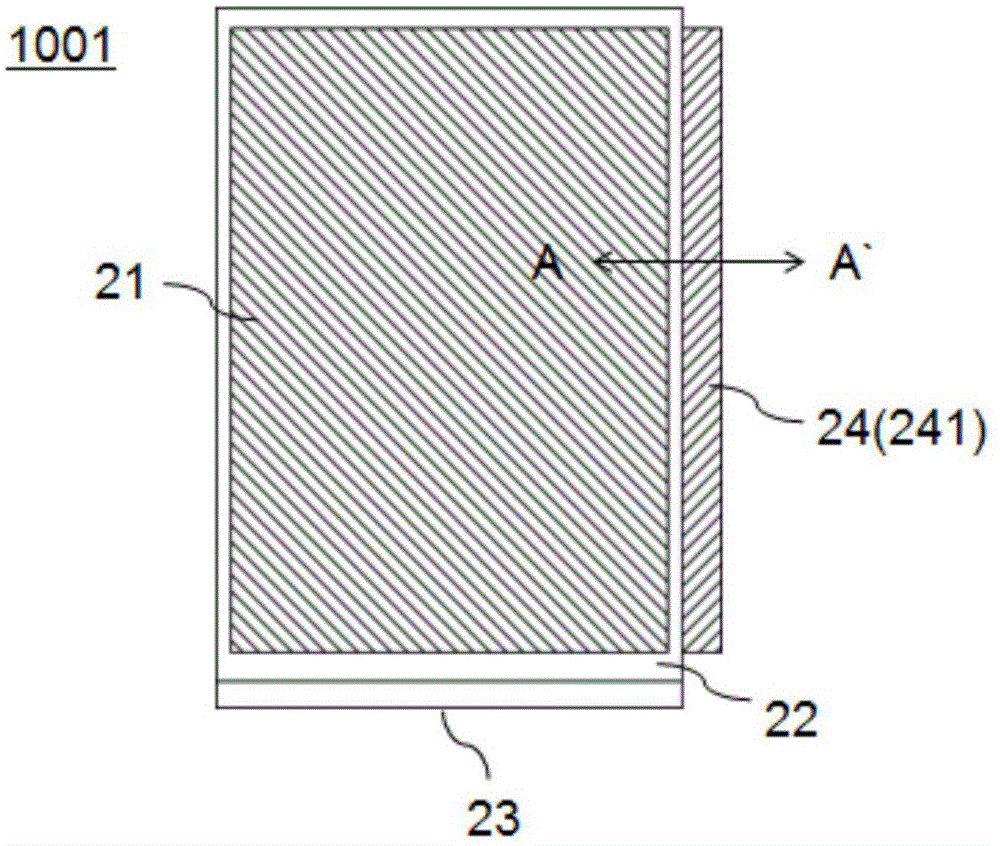

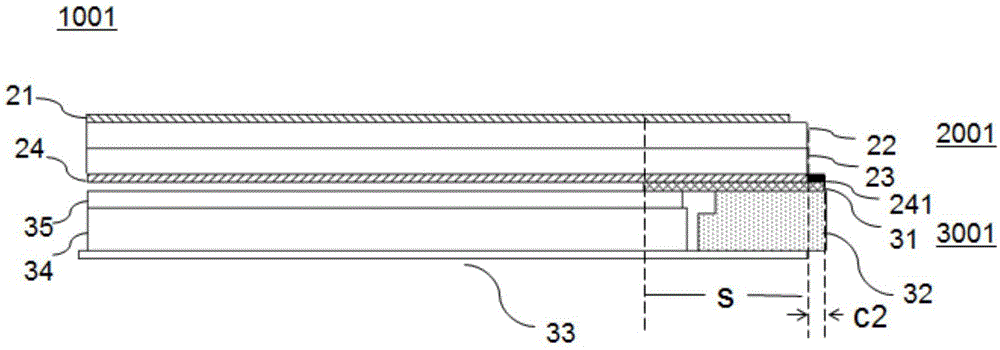

[0025] Please refer to figure 2 and image 3 , figure 2 A top view of a liquid crystal display module 1001 provided in this embodiment, image 3 for figure 2 A cross-sectional view of the liquid crystal display module 1001 along the line A-A'. The liquid crystal display module 1001 includes a backlight module 3001, a liquid crystal display panel 2001 and external components (not shown in the figure). The external component may be a glass cover plate or a touch screen, and is disposed on the liquid crystal display panel 1001 .

[0026] The liquid crystal display panel 2001 includes a first polarizer 21 , a first substrate 22 , a second substrate 23 and a second polarizer 24 . The backlight module 3001 includes an optical film 35 , a light guide plate 34 , a reflection sheet 33 , a plastic frame 32 and a light-shielding tape 31 . The plastic frame 32 is sleeved on the side edges of the light guide plate 34 and the optical film 35 . The optical film 35 includes a diffus...

Embodiment 2

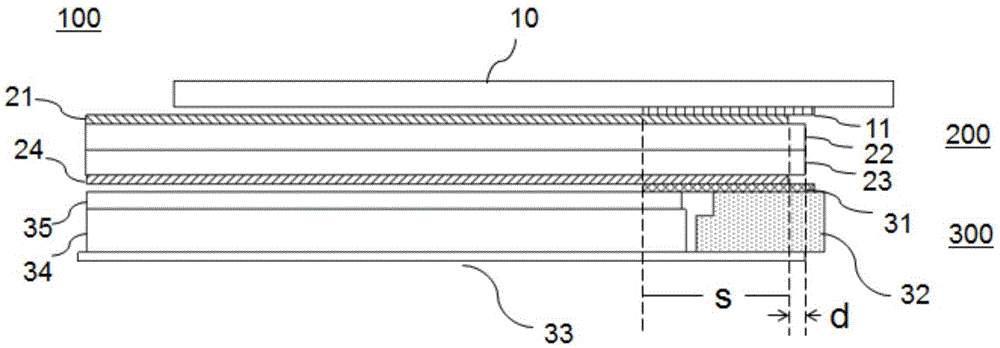

[0030] Please refer to Figure 4 and Figure 5 , Figure 4 It is a top view of another liquid crystal display module 1002 provided in this embodiment, Figure 4 for Figure 5 A cross-sectional view of the liquid crystal display module 1002 along the line A-A'. The liquid crystal display module 1002 includes a backlight module 3002, a liquid crystal display panel 2002 and external components (not shown in the figure). The external component may be a glass cover plate or a touch screen, and is disposed on the liquid crystal display panel 1002 .

[0031] The liquid crystal display panel 2002 includes a first polarizer 21 , a first substrate 22 , a second substrate 23 and a second polarizer 24 . The backlight module 3002 includes an optical film 35 , a light guide plate 34 , a reflection sheet 33 , a plastic frame 32 and a light-shielding tape 31 . The plastic frame 32 is sleeved on the side edges of the light guide plate 34 and the optical film 35 . The optical film 35 inc...

Embodiment 3

[0035] Please refer to Image 6 and Figure 7 , Image 6 It is a top view of another liquid crystal display module 1003 provided in this embodiment, Figure 7 for Image 6 A cross-sectional view of the liquid crystal display module 1003 along the line A-A'. The liquid crystal display module 1003 includes a backlight module 3003, a liquid crystal display panel 2003 and external components (not shown in the figure). The external component may be a glass cover plate or a touch screen, and is disposed on the liquid crystal display panel 1003 .

[0036] The liquid crystal display panel 2003 includes a first polarizer 21 , a first substrate 22 , a second substrate 23 and a second polarizer 24 . The backlight module 3001 includes an optical film 35 , a light guide plate 34 , a reflection sheet 33 , a plastic frame 32 and a light-shielding tape 31 . The plastic frame 32 is sleeved on the side edges of the light guide plate 34 and the optical film 35 . The optical film 35 includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extension distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com