Self-sealing type ultraviolet lamp and manufacturing method thereof

An ultraviolet lamp and ultraviolet technology, which is applied in the field of ultraviolet lamps, can solve the problems of weakened cooling and heat dissipation efficiency of lamps, poor use efficiency of ultraviolet lamps, energy loss of ultraviolet lamps, etc., and achieves good cooling and heat dissipation effect, simple structure, and reduction of scrap. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

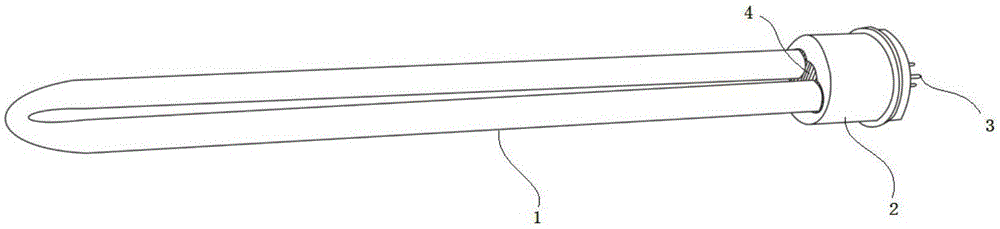

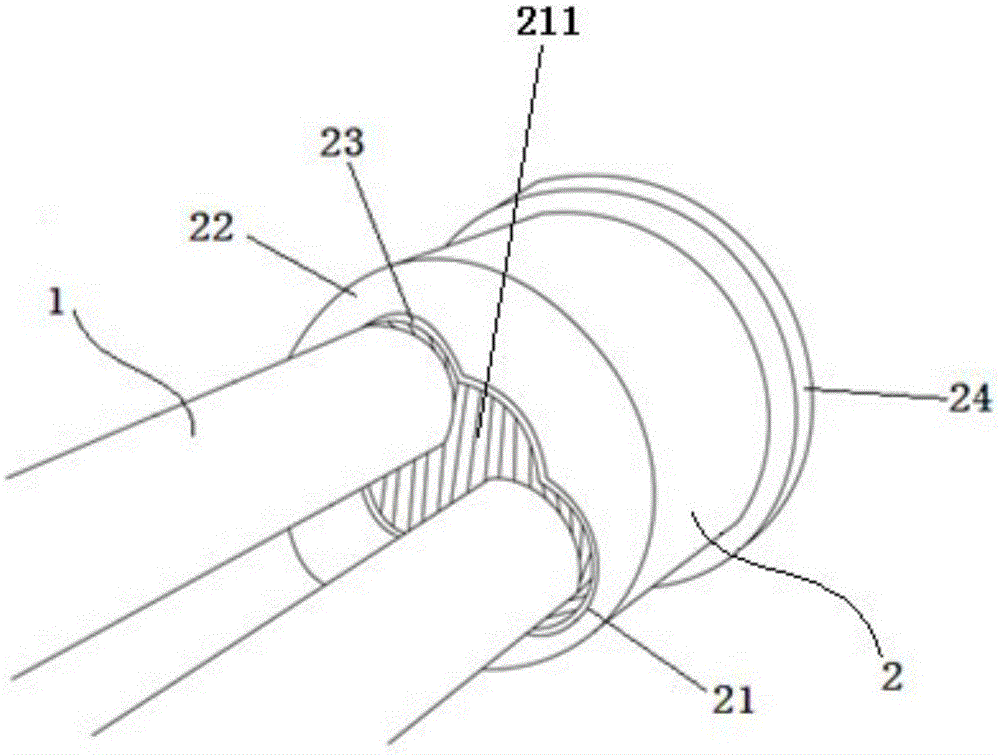

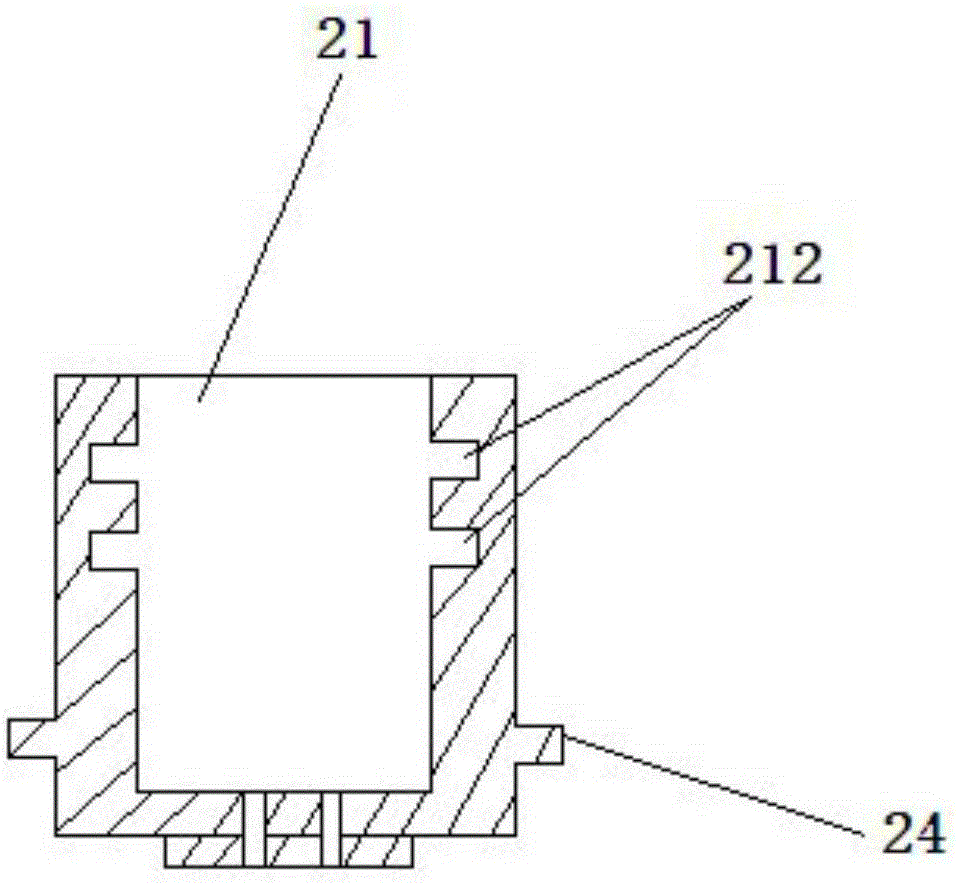

[0024] Such as figure 1 , figure 2 As shown, a self-sealing ultraviolet lamp includes an ultraviolet lamp tube 1 and a lamp holder 2. The ultraviolet lamp tube 1 is a U-shaped tube with metal electrodes 3 protruding from both ends of the same side. The lamp holder 2 is provided with a The positioning hole 21 into which the ultraviolet lamp 1 is inserted, the positioning hole 21 is provided with two holes and a glue filling hole 211, the glue filling hole is located between the two holes and communicates with the two holes. The two electrodes 3 on the side are respectively inserted into the corresponding holes and packaged with the lamp cap 2, and the ends of the electrodes 3 protrude from the bottom of the lamp cap 2 and are exposed outside the lamp cap 2. The apertures of the two holes are slightly larger than the diameter of the ultraviolet lamp tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com