A back contact perovskite solar cell

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of poor stability, restricted practicality, low conversion efficiency of perovskite cells, etc., and achieve the effect of improving conversion efficiency and reducing shading loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

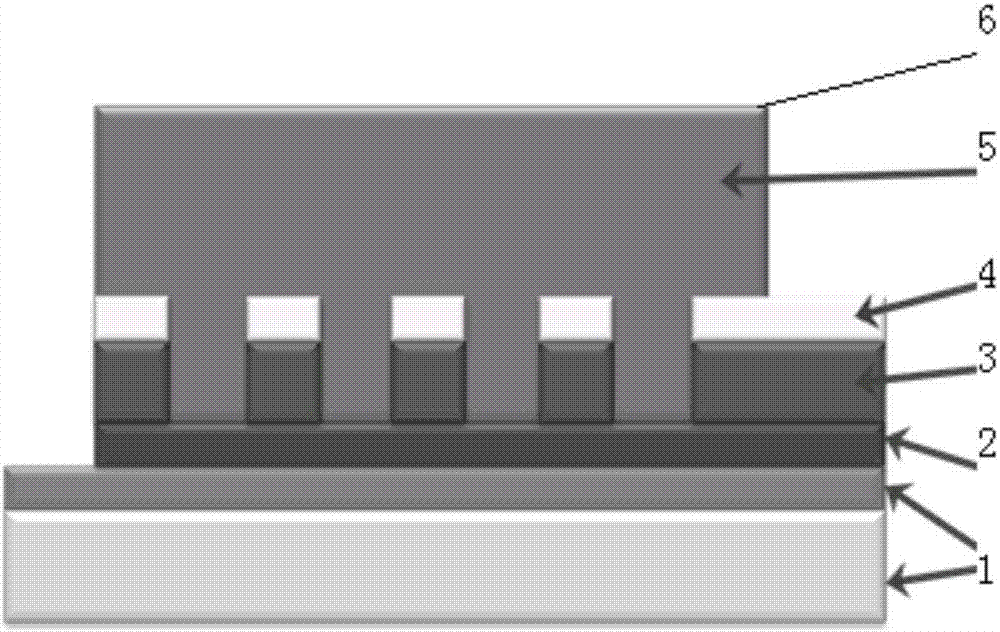

[0024] 1) Substrate 1 is made of FTO transparent conductive glass, and its sheet resistance is ~15Ω / □

[0025] 2) Electron transport layer 2 is made of magnetron sputtered ZnO with a thickness of ~100nm, heat-treated at 400°C and N2 atmosphere for 1h

[0026] 3) The original diameter of the PS beads used is 2um, and the monodisperse layer PS beads are laid by the liquid surface monodisperse layer transfer method, and the monodisperse layer PS beads have a hexagonal close-packed structure.

[0027] 4) Use RIE dry etching to reduce the diameter of PS pellets to 1um

[0028] 5) Al2O3 is prepared by ALD method for the dielectric layer 3, with a thickness of ~50nm

[0029] 6) The metal layer 4 is made of magnetron sputtering Au, with a thickness of ~40nm

[0030] 7) Use toluene ultrasonic to peel off the Al2O3 and Au on the PS ball and its top to form a mesh structure of Al2O3 and Au. The mesh period length is 2um, the mesh diameter is ~1um, and the mesh is also arranged in a hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com