Gear, cam stepless transmissions and vehicles thereof

A continuously variable transmission and continuously variable speed technology, applied in the direction of belts/chains/gears, components with teeth, transmission devices, etc., can solve the problems of speed loss, power loss, and the inability to achieve automatic transmission of mechanical shift cars, etc. Achieve the effect of simple speed control mechanism and oil saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

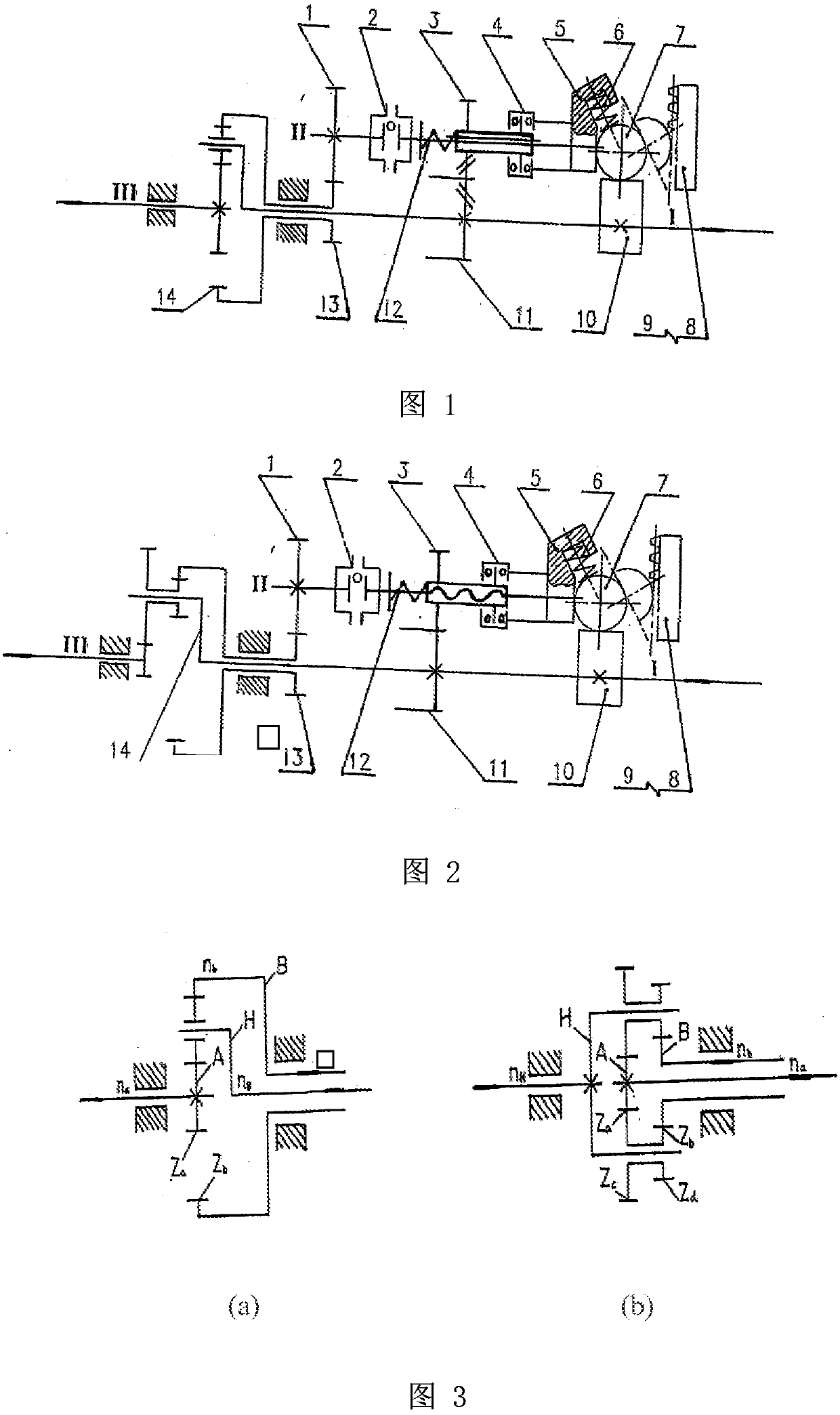

Method used

Image

Examples

example 1

[0123] Example 1: Z 1 = Z 2 =50 teeth, and the modulus m=2. Z 1 Drive Z 2 Turn, Z 1 Turn clockwise, the helical direction of the helical tooth is left-handed, and β=36 degrees. Whenever Z 1 Turn around, Z 2 along the Z 1 The movement distance L of the axis is 20mm.

[0124] Find: in Z 1 Drive Z 2 When turning, whenever Z 1 Turn around, Z 2 along Z 1 When the moving distance L of the axis is 20mm, find the transmission ratio i.

[0125] Solution: 1) Find Z 1 and Z 2 The pitch circle diameter: Φ=Z·m=50×2=100mm

[0126] 2) Calculate the helical lead of the helical gear: P=Φ·π / tan36=432.403133

[0127] 3) Calculate the angle In the case of a feed of 20mm / 2π:

[0128]

[0129] 4) Calculate the transmission ratio i: i=(360+16.651128) / 360=1.046253134≈52.3 / 50=1.046=Z 1 / Z 2

example 2

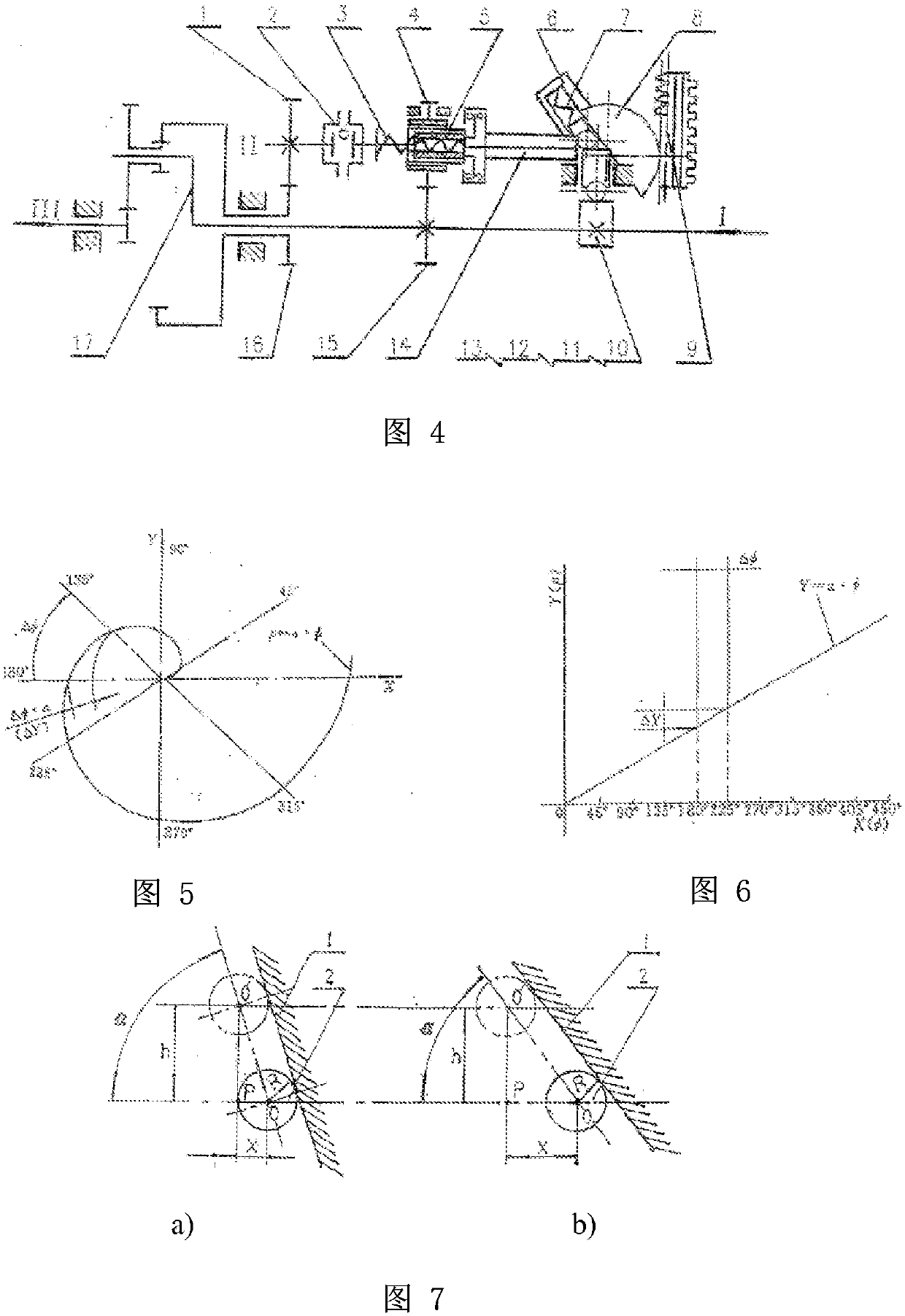

[0130] Example 2: Assuming an involute spline of a helical gear: Z=16, m=2.5, Φ α =42mm, pitch Φ=16×2.5=40mm, helix angle β=35 degrees, Z 1 =Z2=50 teeth, modulus m=2. Z 2 Connected to shaft II via an involute spline. Z 2 The axial movement distance L=18mm (see Figure 8 )

[0131] Find: in Z 1 Drive Z 2 When turning, whenever Z 1 One turn, Z2 along the Z 1 When the moving distance L of the axis is 18mm, find the transmission ratio i.

[0132] Solution: 1) Find the lead of the involute spline: P=40·π / tan35=179.4663715.

[0133] 2) Calculate the angle in the case of a feed of 18mm / 2π

[0134]

[0135] 3) Calculate the transmission ratio i: i=(360+36.35063972) / 360=1.1009739999≈55 / 50=1.1=Z 1 / Z 2 .

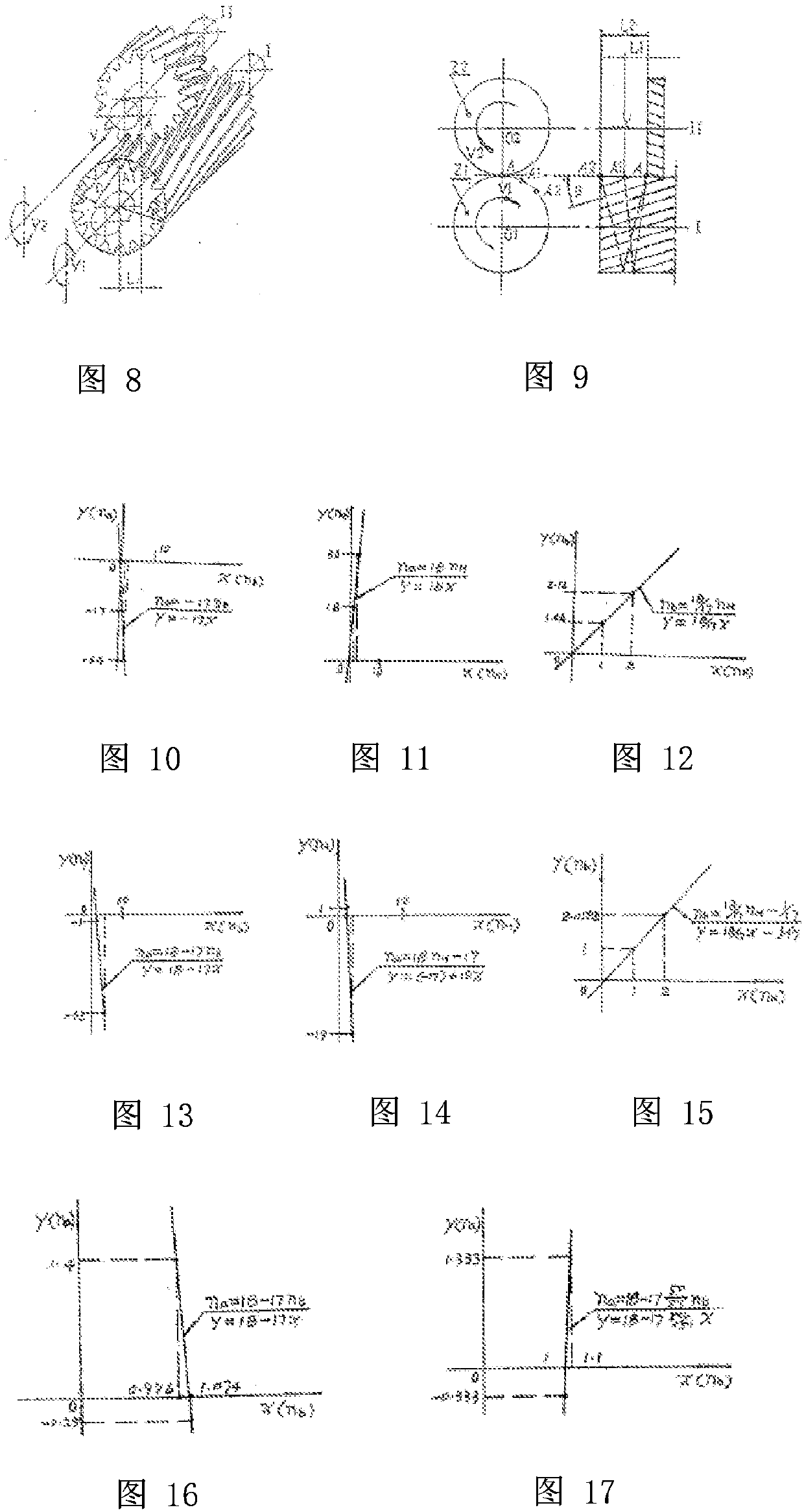

[0136] 2.y=A+B·x

[0137] (1) Linear equations.

[0138] Calculation of the properties of the linear equations of the planetary gear mechanism in which NGW-type and NW-type meshing transmission modes are used according to the general formula used to calculate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com