Method and apparatus for cooling a motor

A motor and equipment technology, applied in the field of equipment for implementing the method, can solve the problems of reduced system efficiency and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

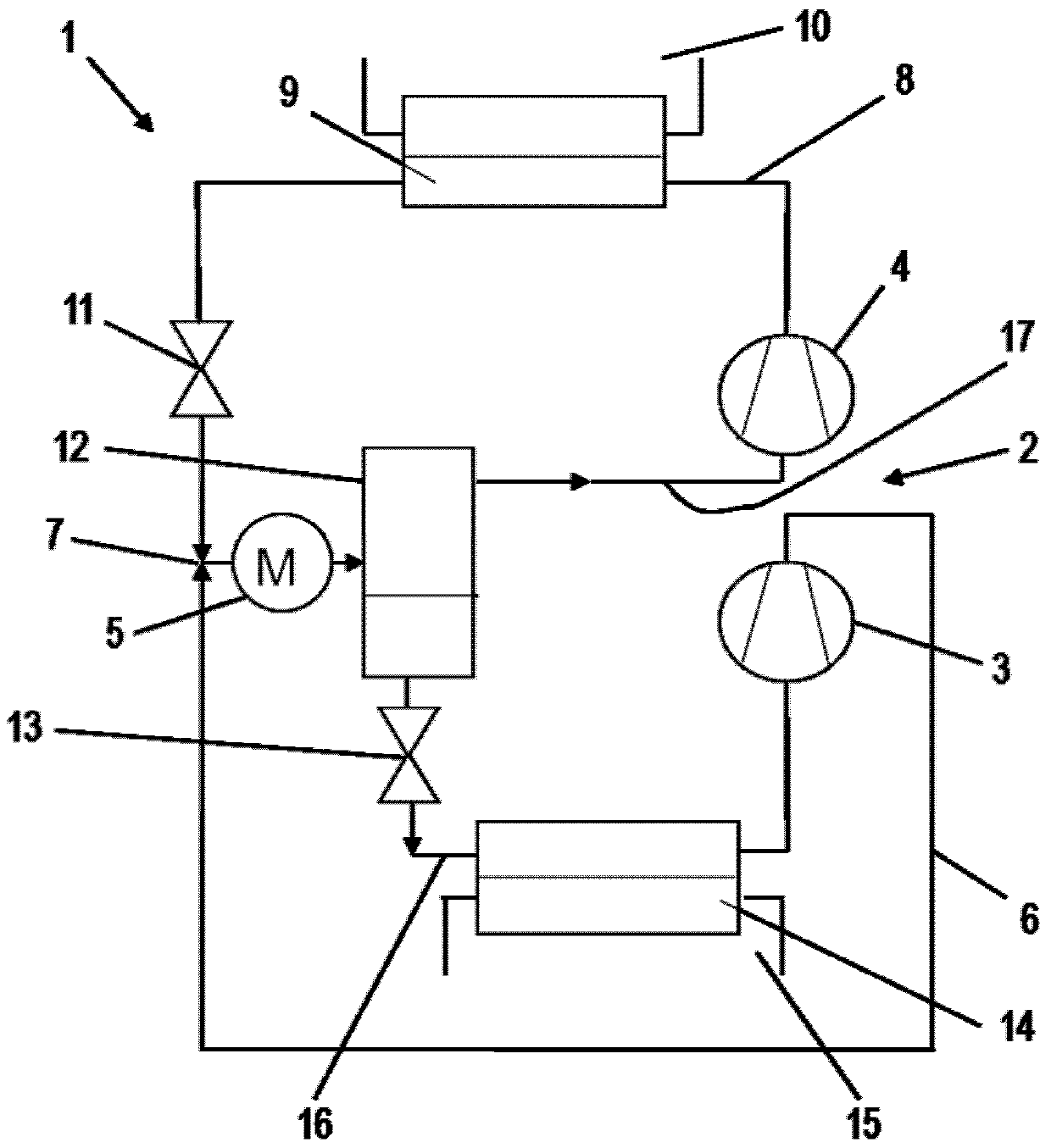

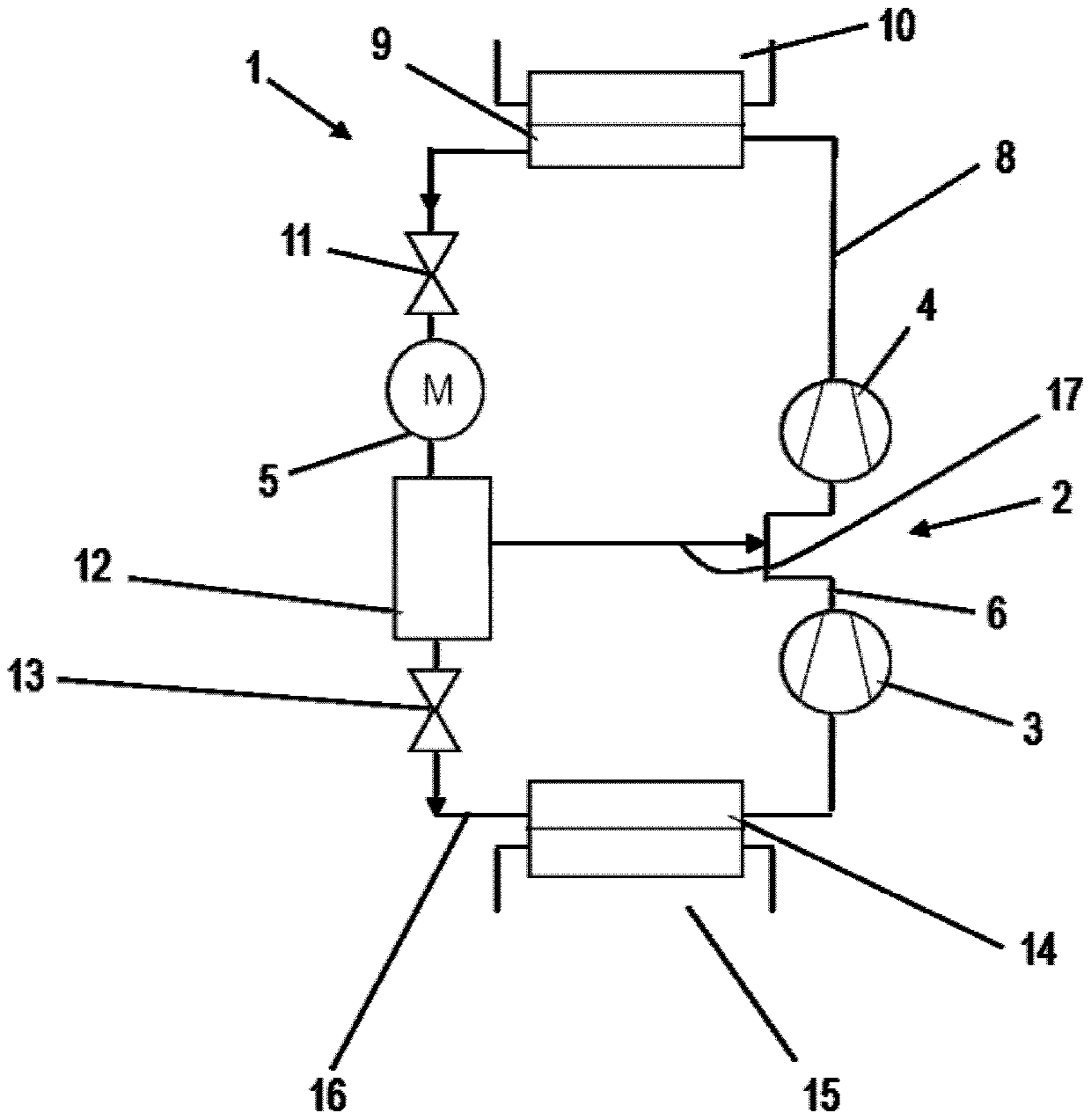

[0029] exist figure 1A coolant circuit 1 of a heat pump with a two-stage compressor 2 comprising a first compression stage 3 and a second compression stage 4 is schematically shown in FIG. The two-stage compressor 2 is driven by a motor 5 , wherein the mechanical connection between the motor 5 and the compression stages 3 , 4 of the two-stage compressor 2 is not shown for the sake of clarity.

[0030] With the aid of the compression stages 3 , 4 of the two-stage compressor 2 , the pressure level of the coolant is first increased from a first pressure level to a medium average level and then to a high pressure level. In this case, a liquid fluid under excess pressure is used as coolant, which fluid is gaseous after depressurization and absorption of heat. The coolant is, for example, gaseous and is fed at low pressure to the first compression stage 3 of the compressor 2 and builds up there at an intermediate pressure level, wherein the coolant is heated at the same time.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com