Plating method for suit sleeve strip matching and check matching

A grid-aligning and strip-aligning technology, which is applied in the direction of sewing tools, clothing, clothing, etc., can solve the problem that sleeves and back garments cannot be aligned horizontally, vertical grids can not be well realized, and cannot be guaranteed Problems such as the back sleeve mountain, achieve the effect of obvious clothing effect, improve the matching effect, and reduce the difficulty of pulling out the sleeve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

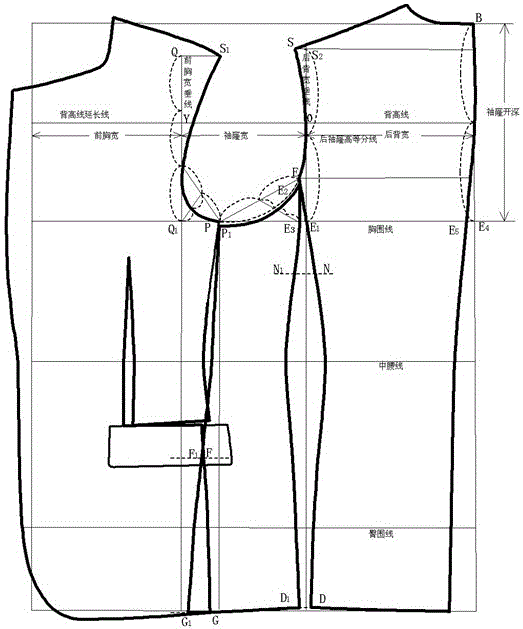

[0027] Such as figure 1 The pattern diagram of the front panel, side panel and back panel of the suit body shown. According to the body size such as bust B, auxiliary lines and basic lines are drawn on the layout map, including bust line, mid-waist line, hip line, front shoulder width QS 1 , shoulder width SS 2 , armhole opening deep BE 4 , front armhole deep QQ 1 , rear armhole height S 2 E. 1 , S 1 is the end point of the front shoulder, S is the end point of the back shoulder, points D and D 1 , N, N 1 ,E 1 ,E 3 , E, E 2 , G 1 , G, F, F 1 ,P 1 , P, etc. are the apposition points of the front piece, side piece, and back piece, point B is the midpoint of the back collar on the back piece, and the front chest width vertical line is a vertical line tangent to the arc of the armhole. When aligning the strips, the bottom edge of the hem seam of the side piece and the back piece is aligned, that is, D in the figure 1 Point and point D are aligned on the same horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com