Vertical hydraulic pipe cold-bending machine

A cold-formed, hydraulic technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of increasing the volume and weight of cold-bending machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The invention provides a vertical hydraulic cold pipe bending machine to solve the technical problem in the prior art that the volume and weight of the cold pipe bending machine need to be significantly increased with the increase of the diameter of the steel pipe.

[0041] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

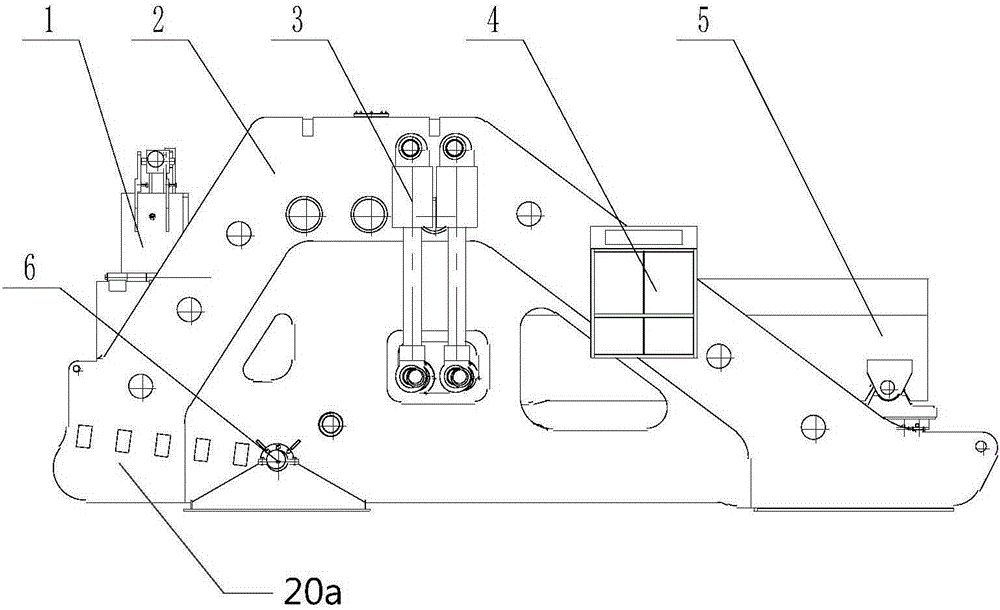

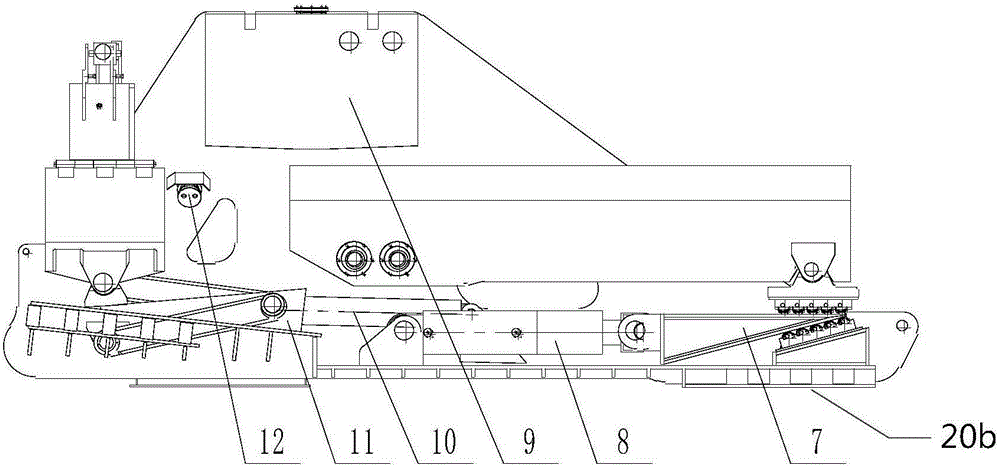

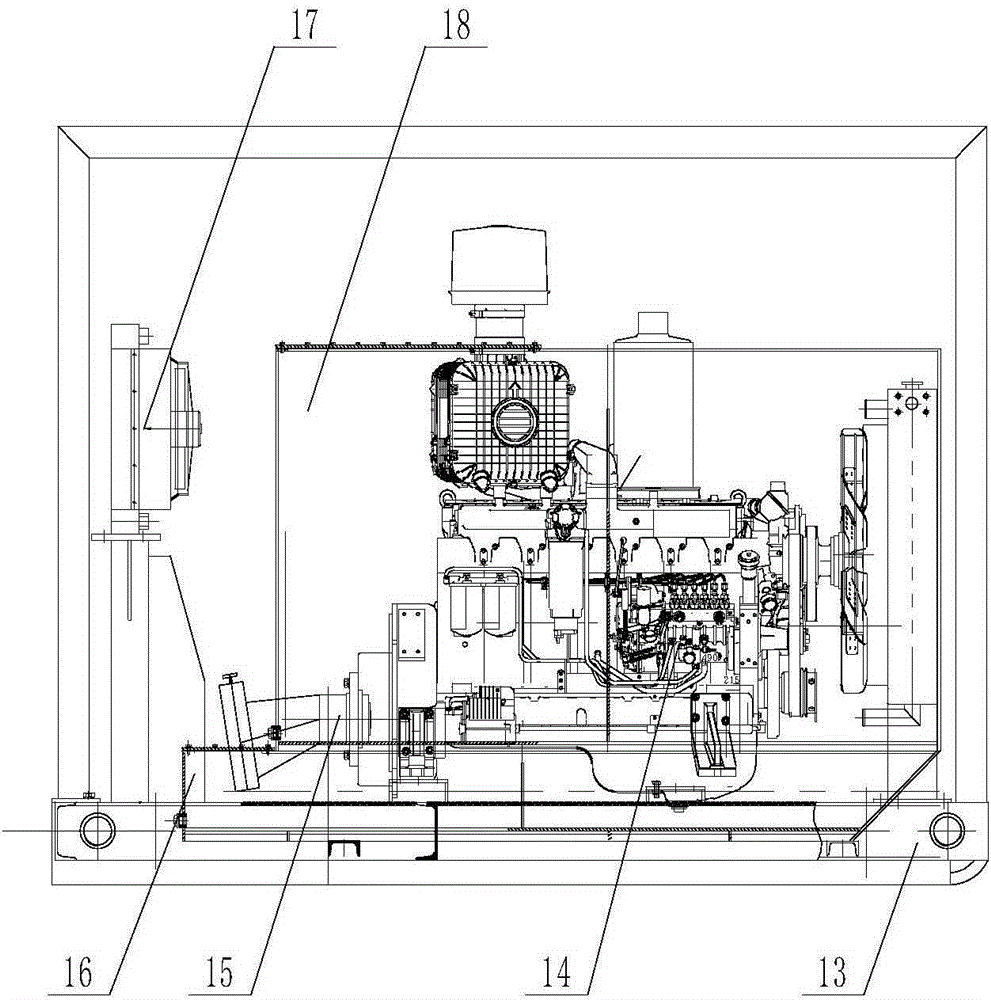

[0042]A vertical hydraulic cold pipe bending machine is provided, comprising: a body assembly, the body assembly including: a left side plate, a right side plate, an upper tire support, a bottom plate, the left side plate is opposite to the right side plate It is arranged and welded together with the bottom plate and the upper tire bracket, and an upper mold is arranged at the bottom of the upper tire bracket; the front tire assembly is arranged on the first side of the body assembly; the roller device is arranged on the One side of the front ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com