Inner-windshield connecting method for motor train unit

A connection method and the technology of the inner windshield, which are applied in the direction of railway car body, railway car body parts, railway transportation, etc., can solve the problems of difficult connection between the inner windshield and the car body, the physical exertion of operators, and the long installation time, etc., to achieve The effect of convenient and quick adjustment, improved comfort and safety, and improved installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

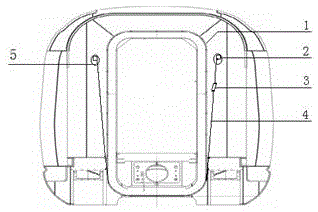

[0009] refer to figure 1 , the specific connection method of the present invention is as follows:

[0010] 1. Install the two lifting rings 5 on the hoisting blocks 2 of the car body on both sides of the inner windshield 1 respectively, hang the two ends of the tension belt 4 on the suspension rings on both sides of the inner windshield 1 respectively, and the tension belt 4 passes through the inner windshield 1. The bottom is connected with the tensioner 3, and the height of the inner windshield can be raised and lowered by operating and adjusting the tensioner 3;

[0011] 2. Adjust the inner windshield 1 to a suitable height by operating the tensioner 3, so that the mounting screw holes of the inner windshield 1 are aligned with the screw holes on the car body mounting seat;

[0012] 3. Use three positioning bolts to fix the inner windshield on the car body mount;

[0013] 4. Adjust the tensioner 3 by operating, adjust and align with the mounting holes, install all the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com