A modular combined manufacturing method for a quadcopter and the quadcopter

A quadcopter, combined technology, applied in aircraft, aircraft parts, rotorcraft, etc., can solve the problems of increasing the overall weight, easy connection problems, and increased failure rates, so as to achieve no increase in the overall weight and no problems. , the effect of increasing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

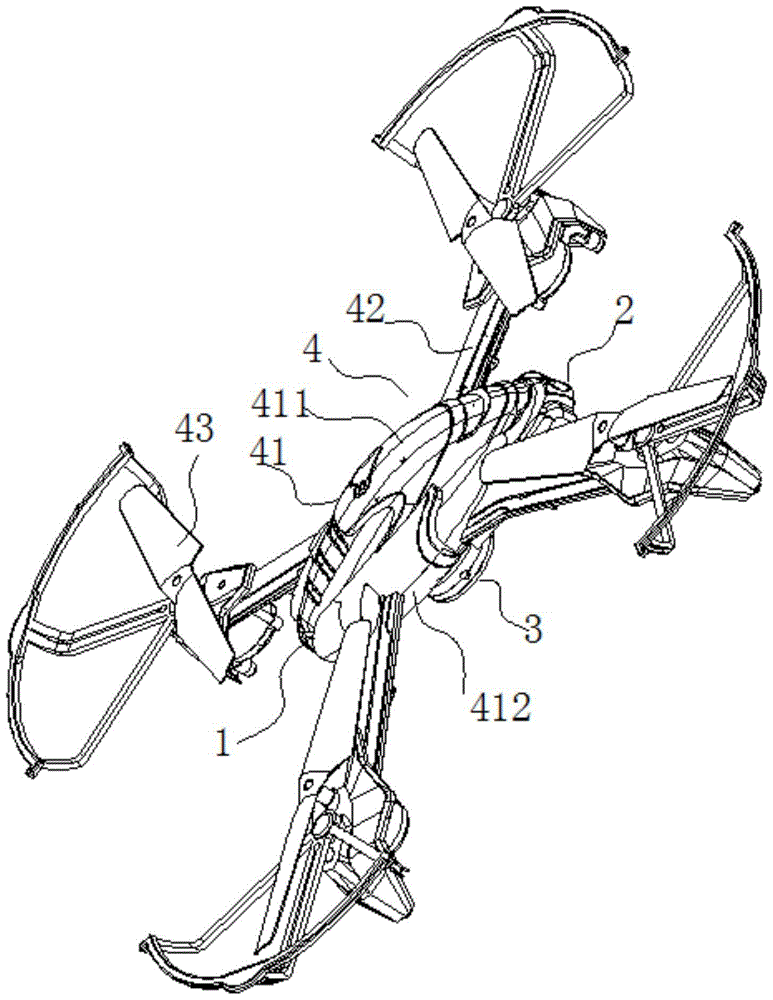

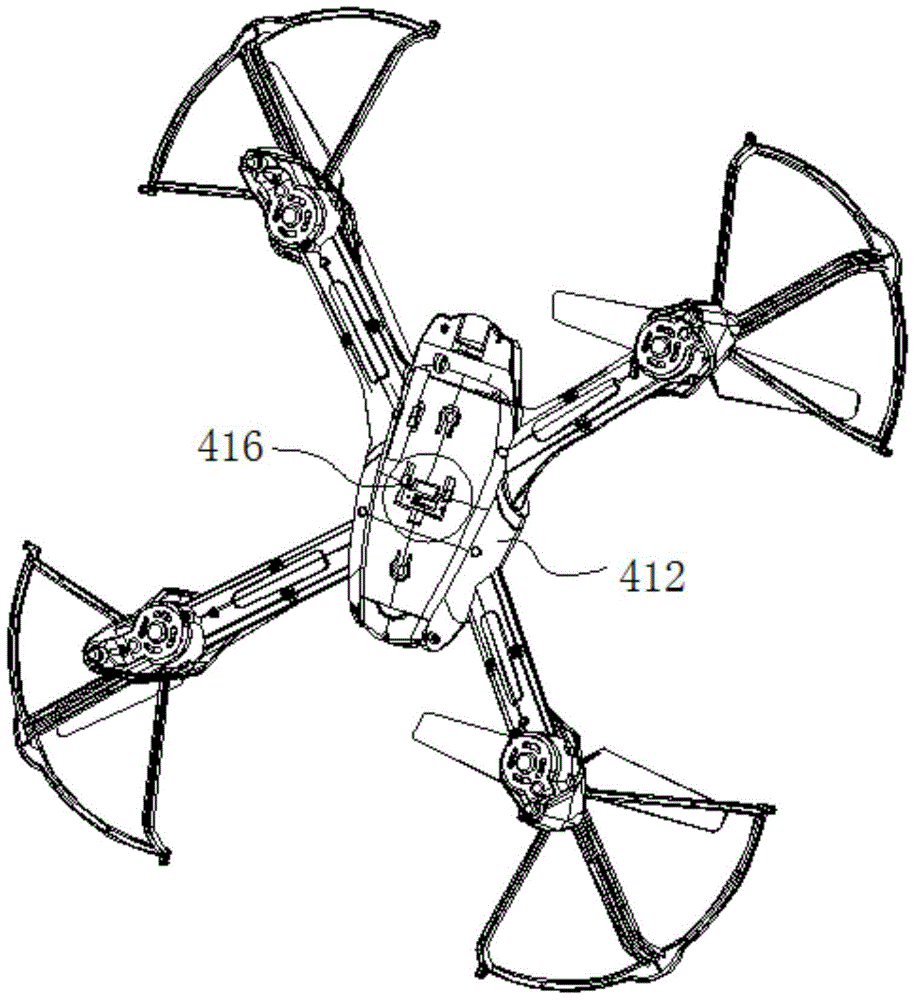

[0045] see Figures 1 to 15 , the modular combined manufacturing method of quadcopter provided by the present invention, comprises the following steps:

[0046] 1) A battery module 1 is provided, the battery module 1 is in the shape of a cuboid, the rear part is provided with a first contact female socket 11, and the bottom part is provided with a first buckle 12;

[0047] 2) A camera module 2 is provided, the camera module 2 is in the shape of a cuboid, the front part is provided with a camera 23, the rear part is provided with a second contact female socket 21, and the bottom part is provided with a second buckle 22;

[0048] 3) The height-fixing and infrared anti-collision module 3 is provided, and the bottom of the height-fixing and infrared anti-collision module 3 is provided with a third buckle 32 and a third contact female socket 31;

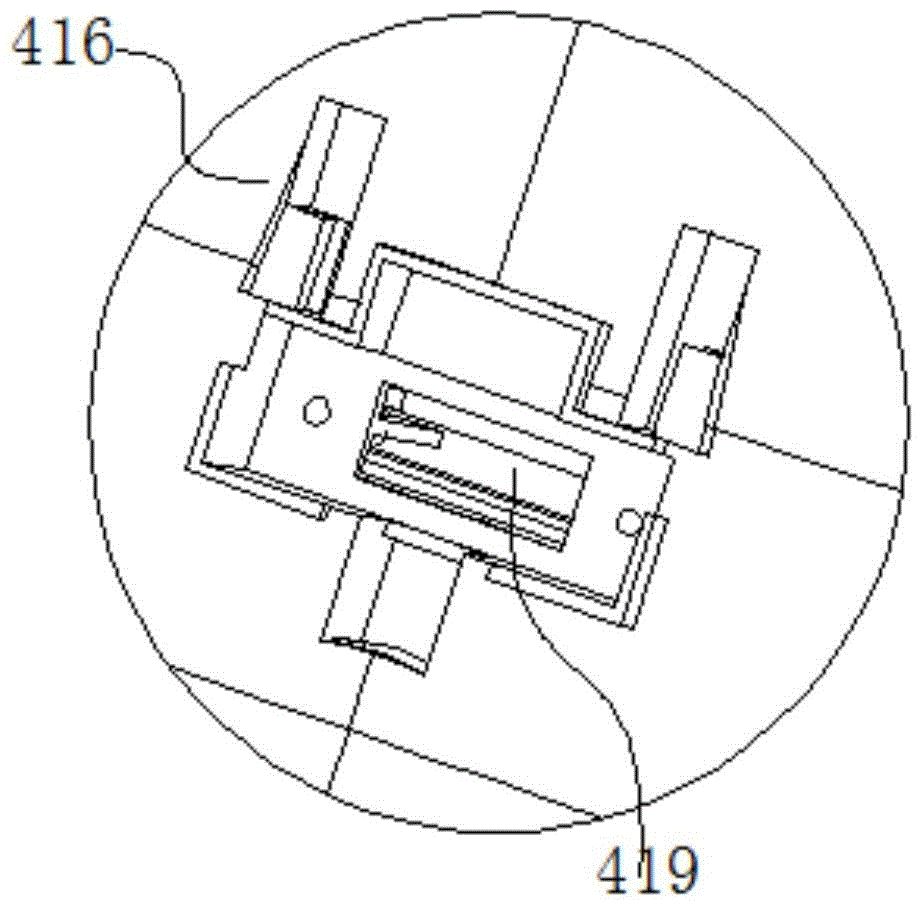

[0049] 4) The aircraft frame module 4 is set, and the four-axis aircraft frame module 4 includes a main body 41, an X-shaped flying sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com