Novel feeding mechanism

A feeding mechanism, a new type of technology, applied in the directions of transportation, packaging, storage devices, etc., can solve the problems of high error rate, high labor intensity, low efficiency of manual sorting, etc., to improve the speed of dispensing, reduce mismatch and mismatch. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be further described in detail below.

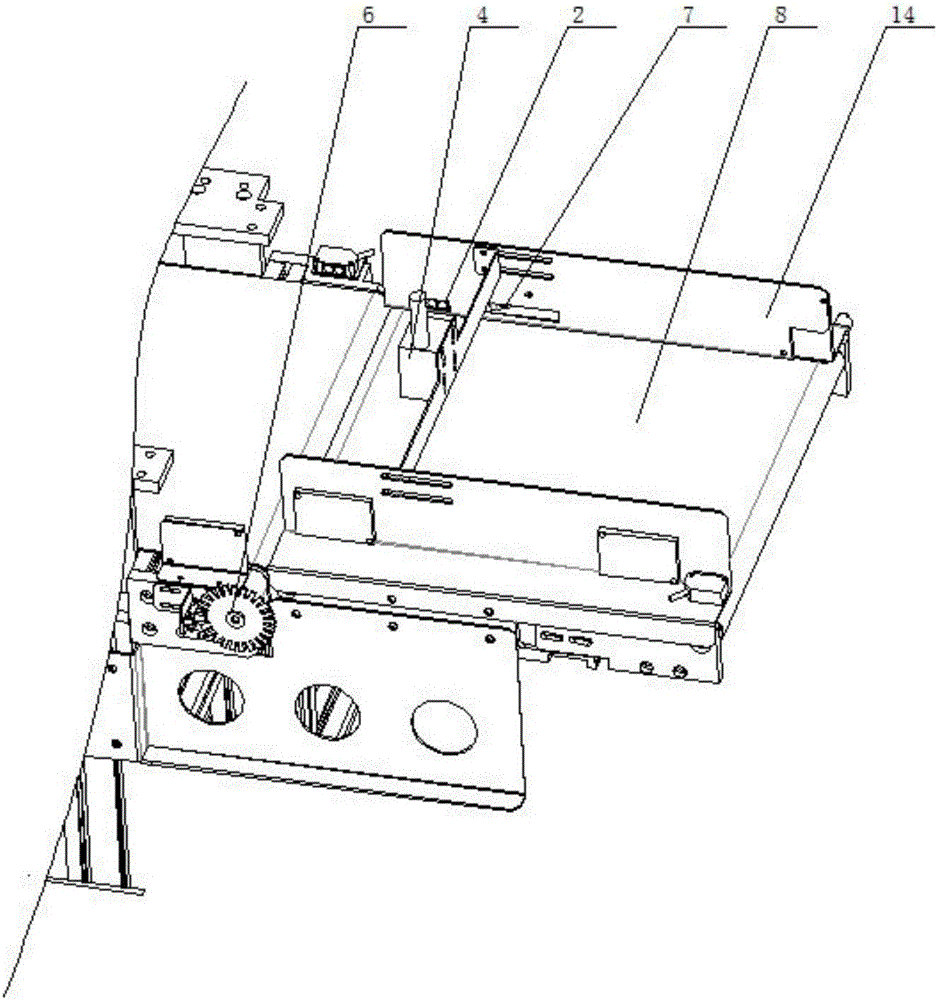

[0017] like figure 1 As shown, the present invention includes a transmission device capable of horizontal and linear motion driven by a first power unit, and is characterized in that it also includes:

[0018] - a first position sensor 2, capable of sensing the medicine located on said delivery device;

[0019] - code scanner 4, capable of identifying the graphic code on the medicine, said code scanner 4 is activated after said medicine is sensed by said first sensor;

[0020] - The code disc 6 is a circular disc-shaped structure and is driven to rotate by the second power device. The end of the code disc 6 is evenly provided with several grid bumps along its circumferential direction, and the code scanner 4 recognizes the pattern After the code is successful, it can rotate a certain number of circles and / or the number of blocks of the bump according to the information correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com