Split Conveyors for Pipelines

A conveying device and split-type technology, applied in the field of split-type conveying devices, can solve the problems affecting the use, danger, rolling, and even rolling out of steel pipes, and achieve the effects of avoiding waste, convenient transportation and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

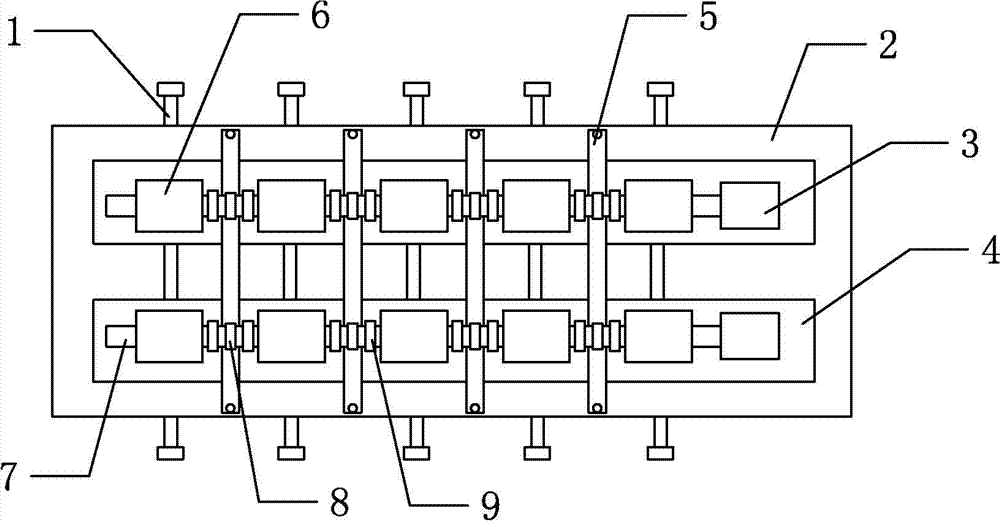

[0019] Among them: double-ended threaded rod 1, support frame 2, motor 3, support plate 4, guide block 5, large-diameter shaft 6, small-diameter shaft 7, coupling 8, and bearing seat 9.

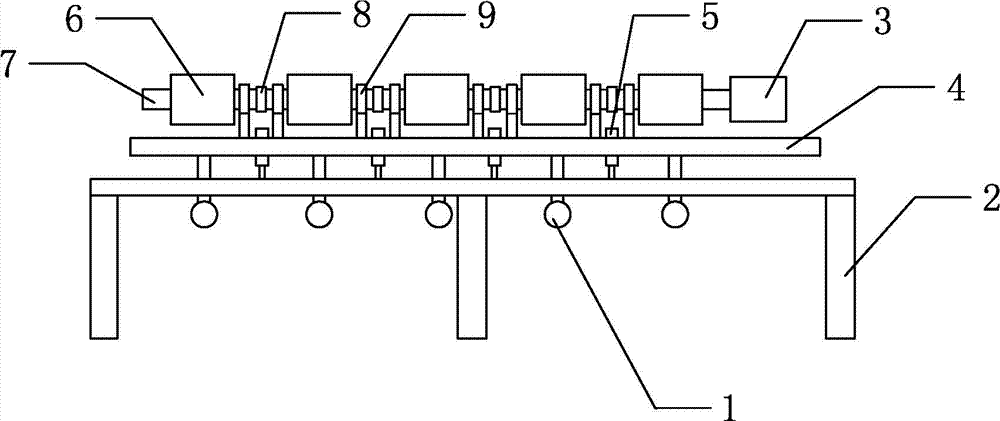

[0020] Such as figure 1 , figure 2 As shown, the split conveying device for pipelines of the present invention includes two rotating shafts located on the same plane, the two rotating shafts are parallel to each other and inclined downward along the direction of transmission, and each rotating shaft is connected with a motor 3, and the motor 3 Starting can drive the rotating shaft to rotate.

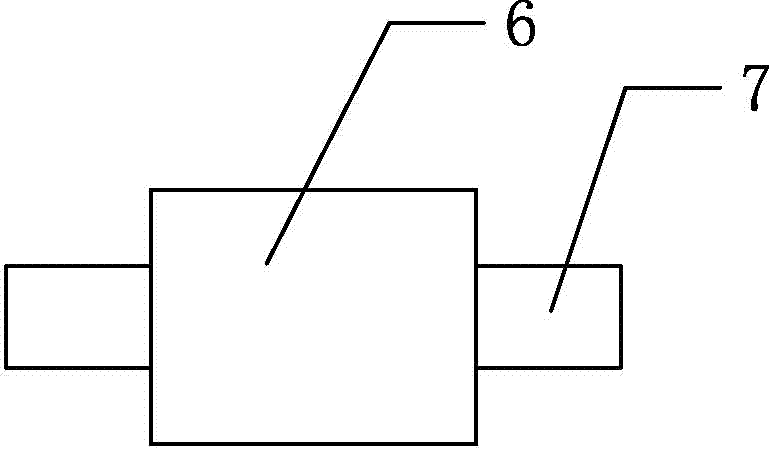

[0021] Each rotating shaft includes five sub-shafts, and each sub-axis includes a large-diameter shaft 6 and two small-diameter shafts 7, and the large-diameter shaft 6 is located between the two small-diameter shafts 7, as image 3 As shown, the outer wall of the large-diameter shaft 6 is covered with rubber, and the outer wall of the rubber is provided with a spiral texture. The spiral direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com