Fill interception and channeling system

An intercepting wall and intercepting net technology, applied in the field of sewage treatment, can solve the problems of increasing the moving speed of the filler, the area of the intercepting net is large, and the operating cost is increased, and achieves the effect of improving the flow rate of the via hole, reducing the operating cost and saving materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

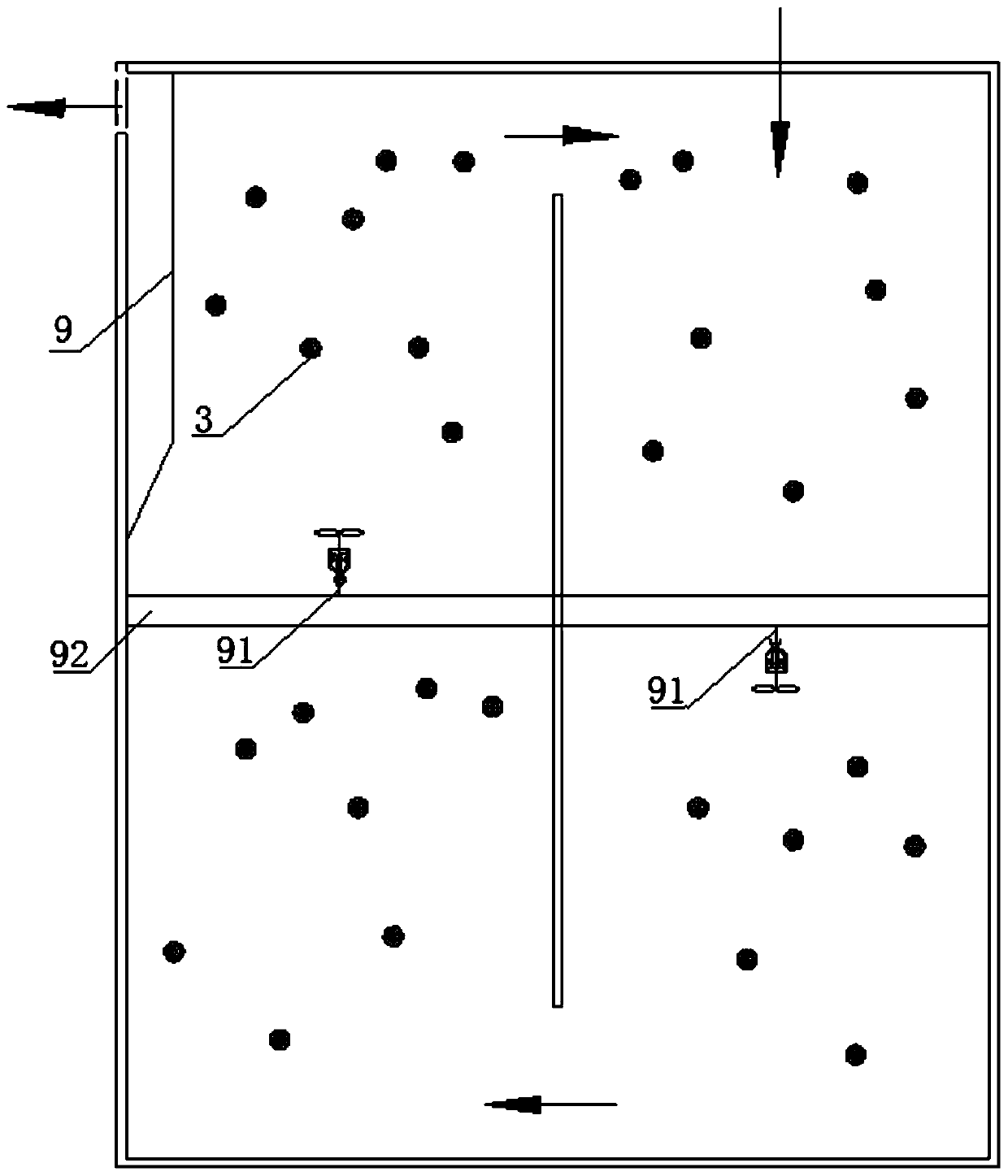

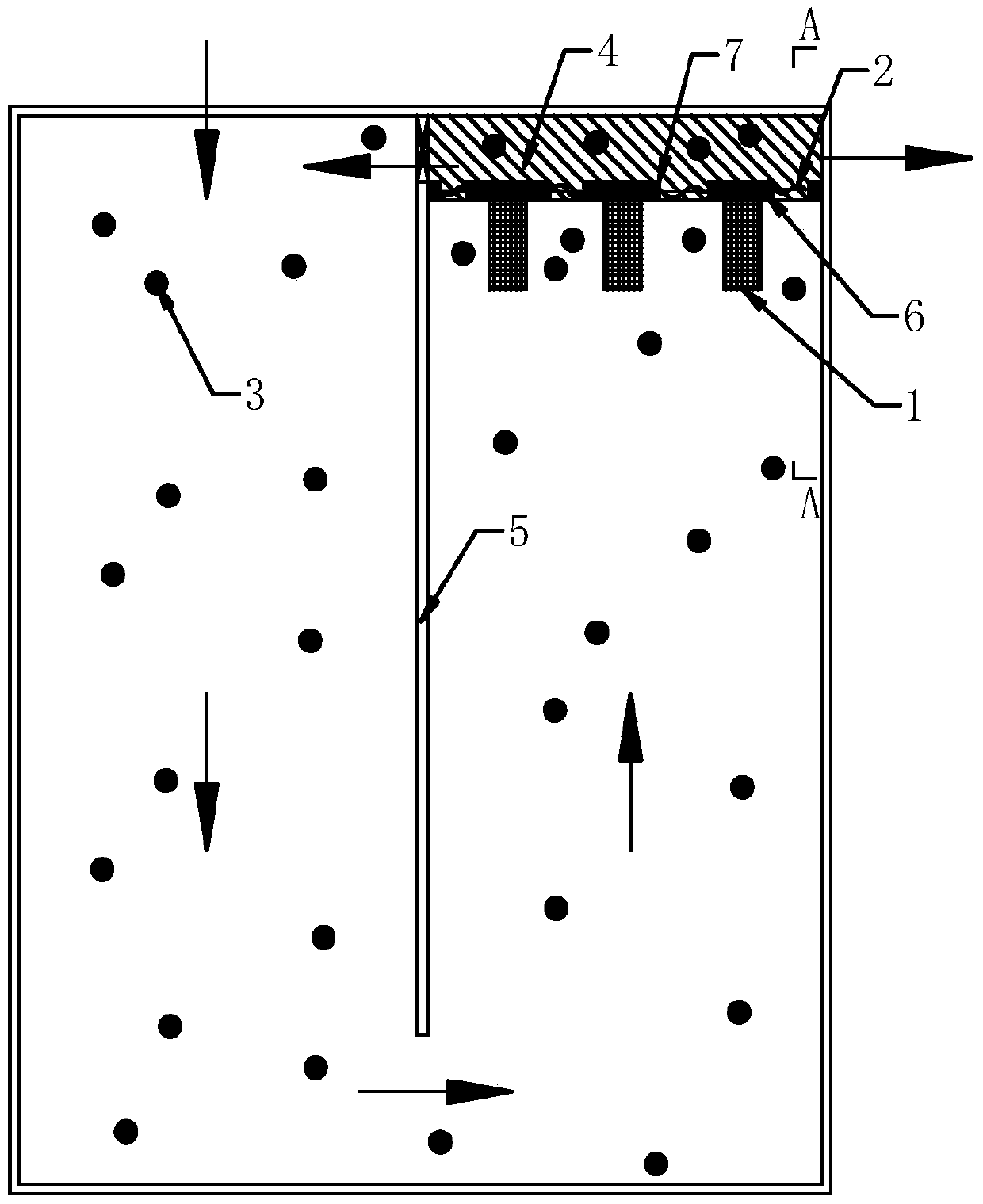

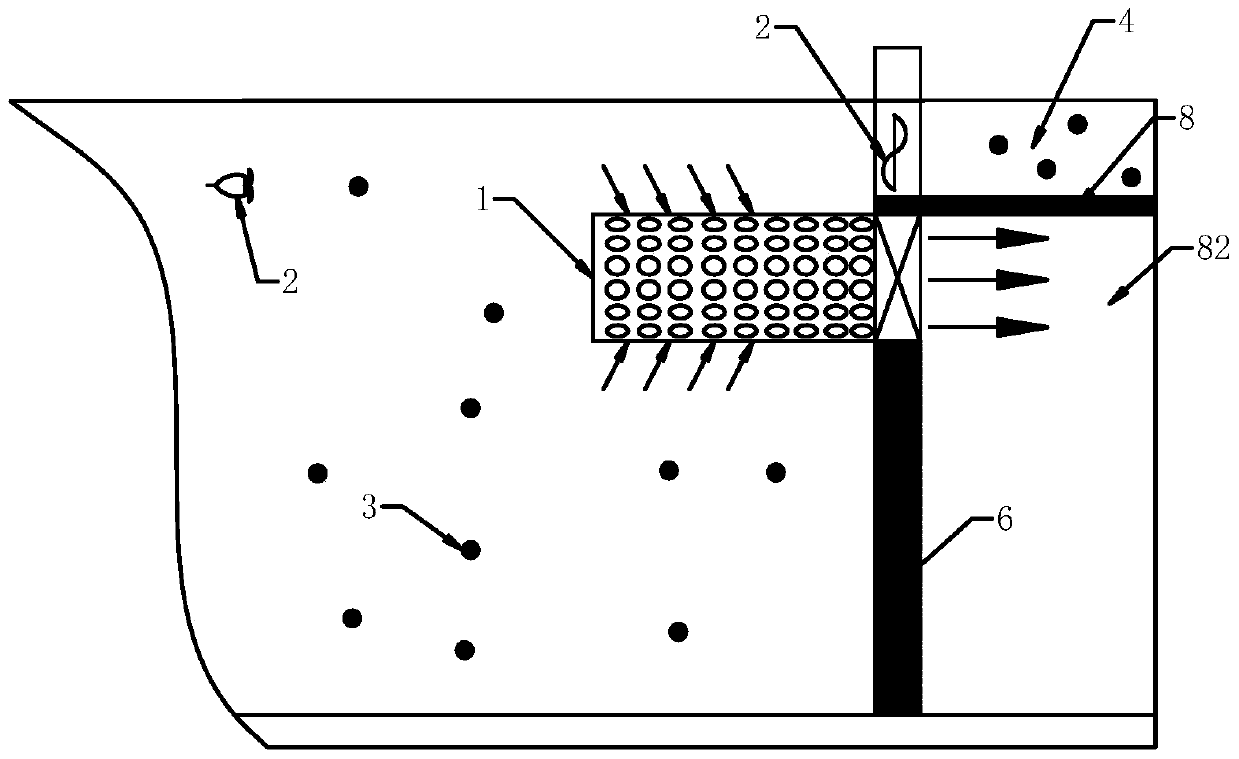

[0022] like figure 2 , image 3 As shown, the filler interception and dredging system of the present invention is provided with a diversion wall 5 along the length direction in the sewage treatment tank, the front end of the diversion wall 5 is attached to the front pool wall, and the rear end of the diversion wall 5 is connected to the rear pool. Keep the distance between the walls, the water inlet is arranged on one side of the front end of the diversion wall 5, and the water outlet is arranged on the other side of the front end of the diversion wall 5, the sewage enters the pool from the water inlet, bypasses the rear end of the diversion wall 5, and Turn around in the pool. In front of the water outlet, there is an interception wall 6 that is hard to the direction of the water flow. The middle part of the interception wall 6 is provided with a drainage hole, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com