Construction method for rigid pile composite foundation

A technology of composite foundation and construction method, which is applied in the direction of foundation structure engineering, soil protection, construction, etc., to achieve the effect of reducing the number, increasing the ability to bear loads, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

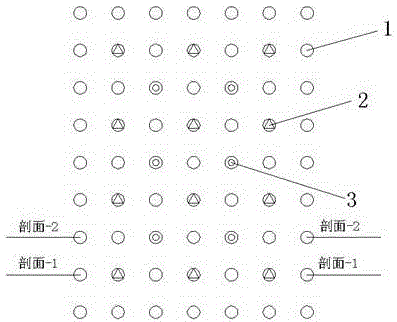

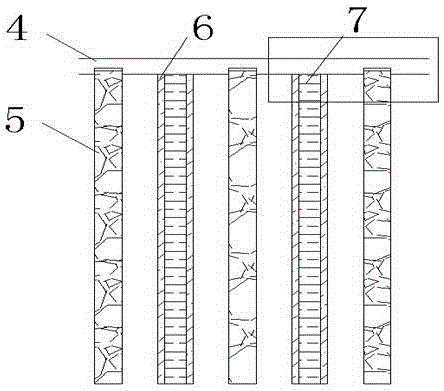

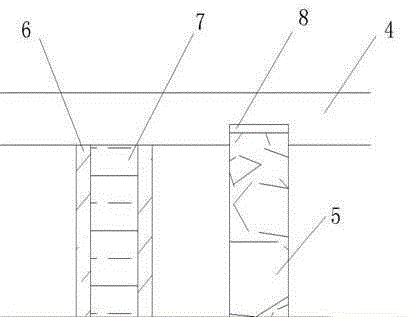

[0043] Please refer to Figure 1~Figure 5 , figure 1 A construction layout diagram provided for the embodiment of the present invention; figure 2 yes figure 1 Sectional view of middle section 1; image 3 yes figure 2 Enlarged view of the boxed part; Figure 4 yes figure 1 Case 1 of the sectional view of the middle section 2; Figure 5 yes figure 1 Case 2 of the cross-sectional view in section 2.

[0044] The embodiment of the present invention provides a construction method of rigid pile composite foundation, comprising the following steps:

[0045] Step 1, determine the rigid pile points and loose pile points in the construction area:

[0046] Step 1-1. Determine the rigid pile points: In the construction area, arrange the rigid pile points 2 evenly according to the design requirements, and require the interval between any two adjacent rigi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com