Rotating drum type swirl curing and stirring device and dredged sludge hydraulic reclamation method

A stirring device and dredging technology, which is applied to mechanically driven excavators/dredgers, water filling, soil protection, etc., can solve the problem that the stability and long-term safety of dredged soil cannot be guaranteed, and the impact of dredged dredging Problems such as solidification efficiency and effect, solidified silt strength not up to design standards, etc., achieve the effect of reducing manpower and material resources input, shortening construction period, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

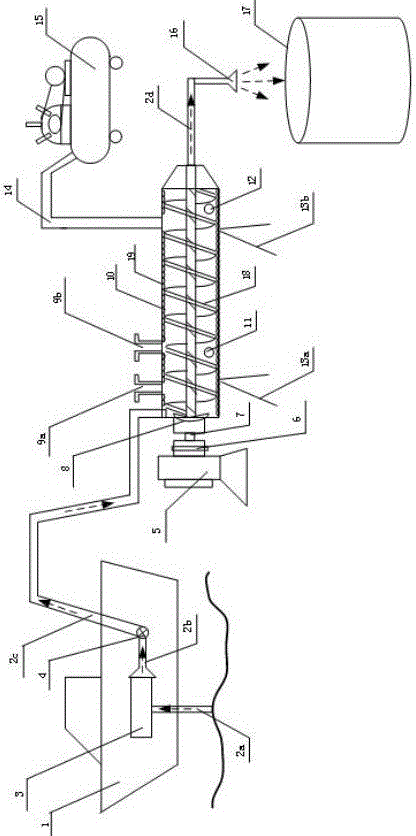

[0025] like figure 1 , figure 2 The shown rotary drum type vortex solidification mixing device comprises a dredger 1, a cylindrical mixing drum 19 and a motor 5, and a support is provided below the cylindrical mixing drum 19, and the support includes two ends arranged on the cylindrical mixing drum 19. The first bracket 13a and the second bracket 13b.

[0026] In the dredger 1, a mud storage box 3 is provided, the bottom of the mud storage box 3 is connected with a suction pipe 2a extending to the bottom of the dredger 1, and the end is connected with a mud discharge pipe 2b, and the end of the mud discharge pipe 2b is provided with The mud pump 4 is connected with the mud delivery pipe 2c whose end is connected to the rear end of the cylindrical mixing drum 19 at the outlet of the mud pump 4 .

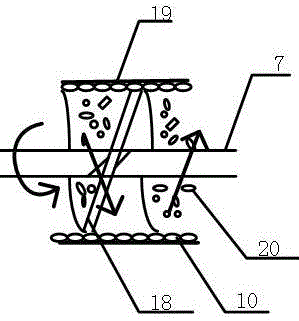

[0027] Inside the cylindrical mixing drum 19 is provided with a screw mud pusher 18, the rear end is provided with a bearing 7, the front end is connected with a mud blowing pipe 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com