A box-shaped steel frame composite column and its manufacturing method

A technology of combining columns and steel frames, applied in the field of electric wires, can solve the problems of many types of materials, increase the cost of developers, and large quantities, and achieve the effect of solving potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

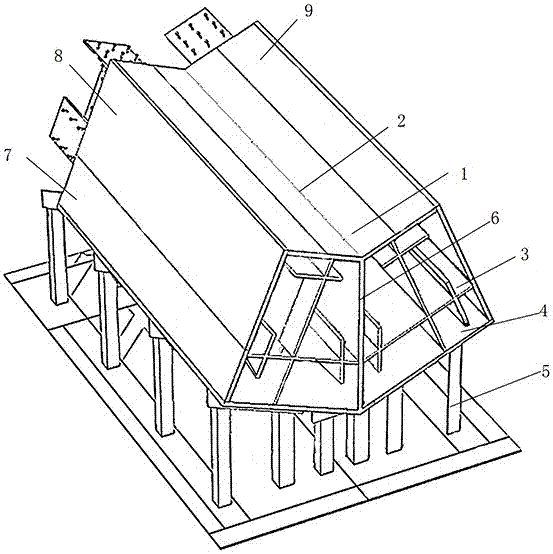

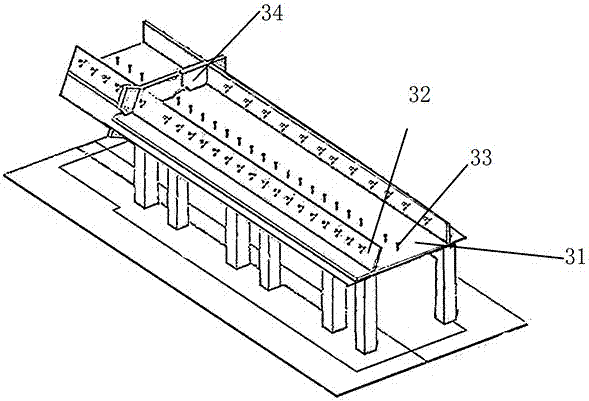

[0033] Such as figure 1 and figure 2 The box-shaped steel frame composite column shown includes: folded plate 1, anti-deformation knuckle line 2, unit element a3, bottom plate 4, support frame 5, partition plate 6, side seam plate 7, side plate 8 and cover plate 9 , the unit unit a3 is composed of a base plate 31 , a clamping plate 32 , pegs 33 and a partition plate 34 .

[0034] The relationship between the above components is as follows:

[0035] The anti-deformation knuckle line 2 is arranged in the middle of the folded plate 1, the folded plate 1 is arranged on the top of the partition plate 6, the unit element a3 and the bottom plate 4 are arranged on both sides of the partition plate 6, and the support The tire frame 5 is fixed at the designated place for construction, the partition plate 6 is set on the supporting tire frame 1, the side seam plate 7 is connected between the unit element a3 and the bottom plate 4, and the side plate 8 is arranged between the two units...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com