Rope coring positioning suspension mechanism with in-place notifying function

A suspension mechanism and rope technology, applied in the field of rope coring positioning suspension mechanism, can solve the problems of high labor intensity, large pressure loss, long working time, etc., and achieve the effect of reducing working time, small working pressure loss, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

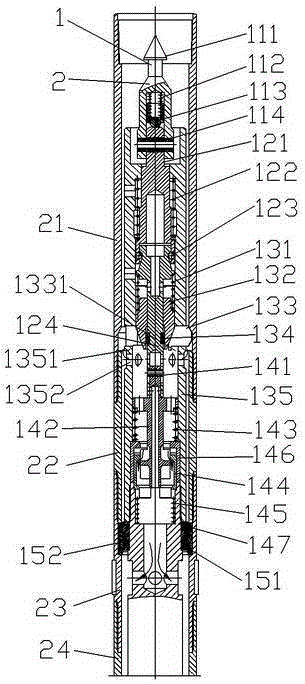

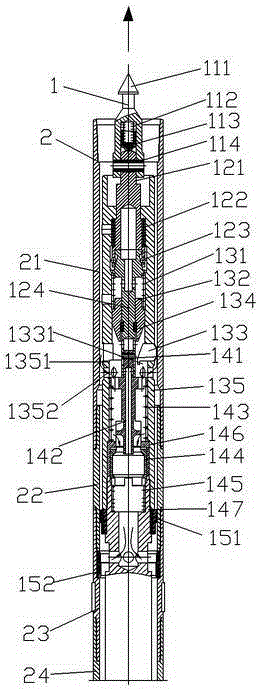

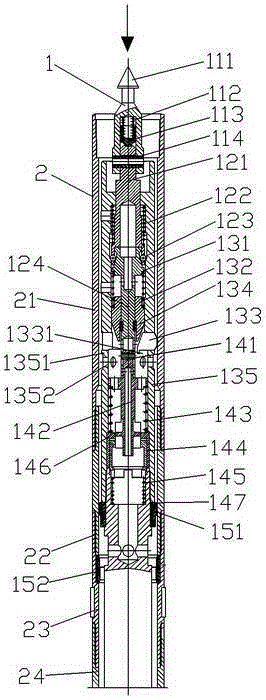

[0029] see figure 1 As shown, the present invention is composed of an inner tube assembly 1 and an outer tube drilling tool 2, and the inner tube assembly 1 is arranged inside the outer tube drilling tool 2;

[0030]The inner pipe assembly 1 includes a rope fishing device 11, a locking device 12, a positioning device 13, an in-position reporting device 14 and a suspension device 15. The rope fishing device 11 is hinged on the upper end of the locking device 12, and the upper end of the positioning device 13 is fixed on the The lower end of the locking device 12, the upper end of the in-position signaling device 14 are hinged at the lower end of the positioning device 13, and the suspension device 15 is arranged at the lower end of the in-position signaling device 14;

[0031] The rope fishing device 11 comprises a spear head 111, a spear head spring 112, a block 113 and a spear head elastic pin 114, the spear head spring 112 and the block 113 are arranged in the spear head gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com