Hydraulic optimization method for flow channel type guide vane of multistage centrifugal pump under multiple working conditions

A technology of hydraulic optimization and centrifugal pump, which is applied in the directions of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems such as public reports on the hydraulic optimization method of multi-stage centrifugal pump flow channel guide vanes under multiple working conditions, etc. The effect of improving weighted average efficiency and saving economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

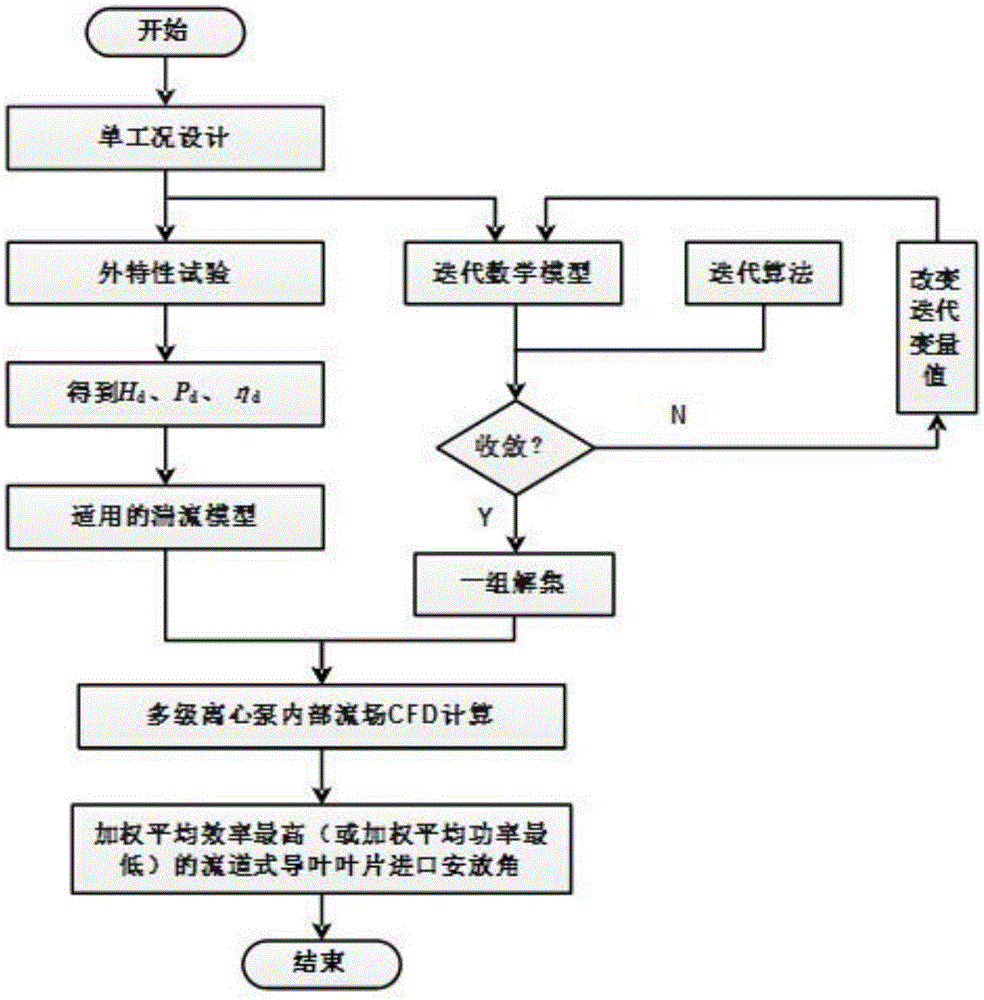

Method used

Image

Examples

Embodiment

[0039] A three-stage centrifugal pump with a specific speed of 154, its design flow rate is Q d =850m 3 / h, H d =131m, n=1475r / min.

[0040] (1) Build the test bench for the external characteristics of the three-stage centrifugal pump, and measure the flow rate, lift, power and efficiency of the three-stage centrifugal pump under the design conditions.

[0041] The three-stage centrifugal pump is designed by using the design method of single working condition (namely design working condition). Process three-stage centrifugal pumps and build a three-stage centrifugal pump external characteristic test bench. Measure the flow, head, power and efficiency of three-stage centrifugal pumps under design conditions. The flow rate Q of the three-stage centrifugal pump under the design working condition d It is measured by the turbine flowmeter on the pump outlet pipeline system, and its head H d Measured by the pressure sensors at the inlet and outlet of the pump, its power P d M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com