Anti-corrosion and waterproof magnetic sensor production equipment

A technology for production equipment and magnetic sensors, which is applied in the field of anti-corrosion and waterproof magnetic sensor production equipment, can solve the problems of high labor costs, slow bonding speed, and affecting the performance of finished products, and achieve the goals of improving baking efficiency, consistent shrinkage, and accelerating bonding speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

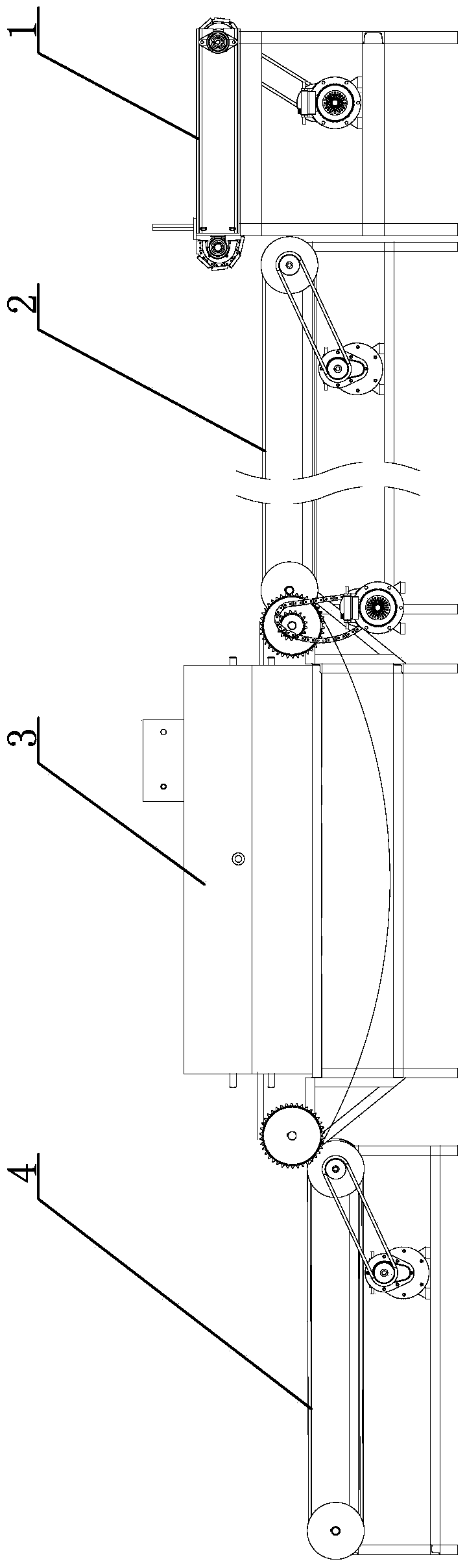

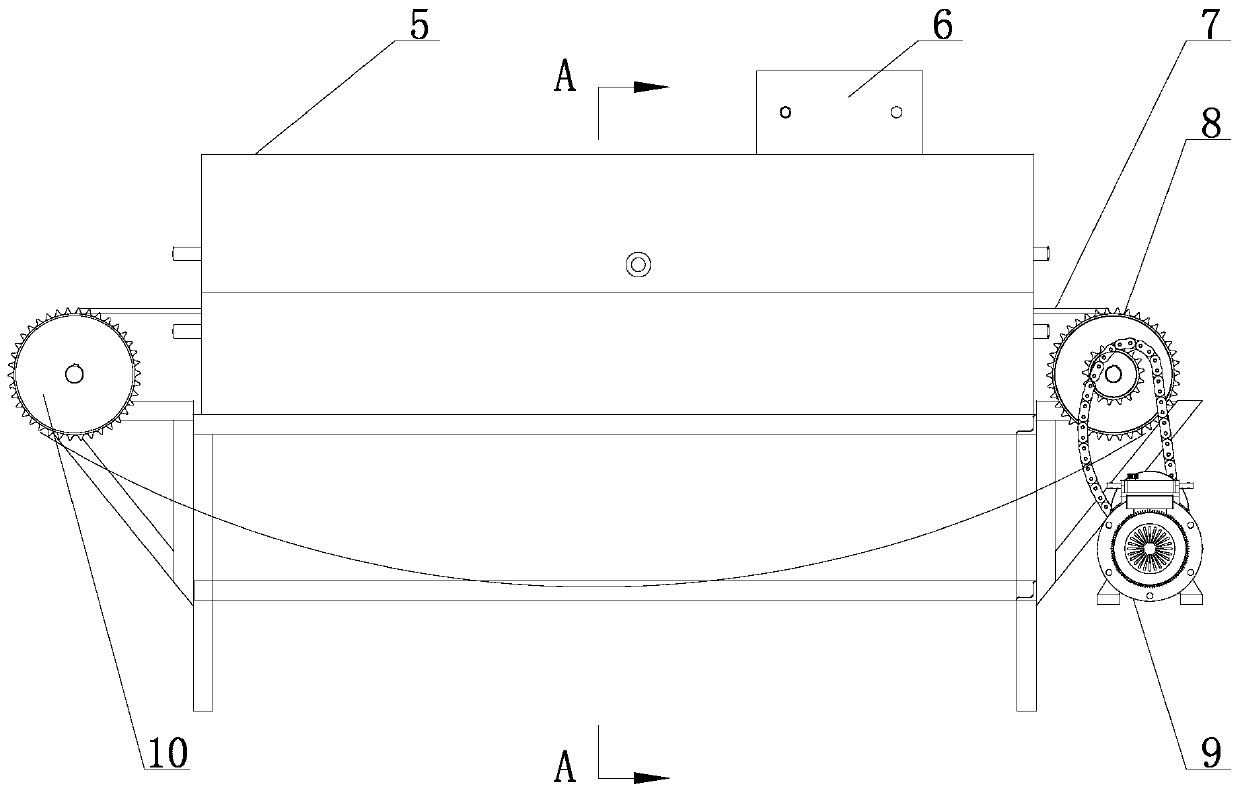

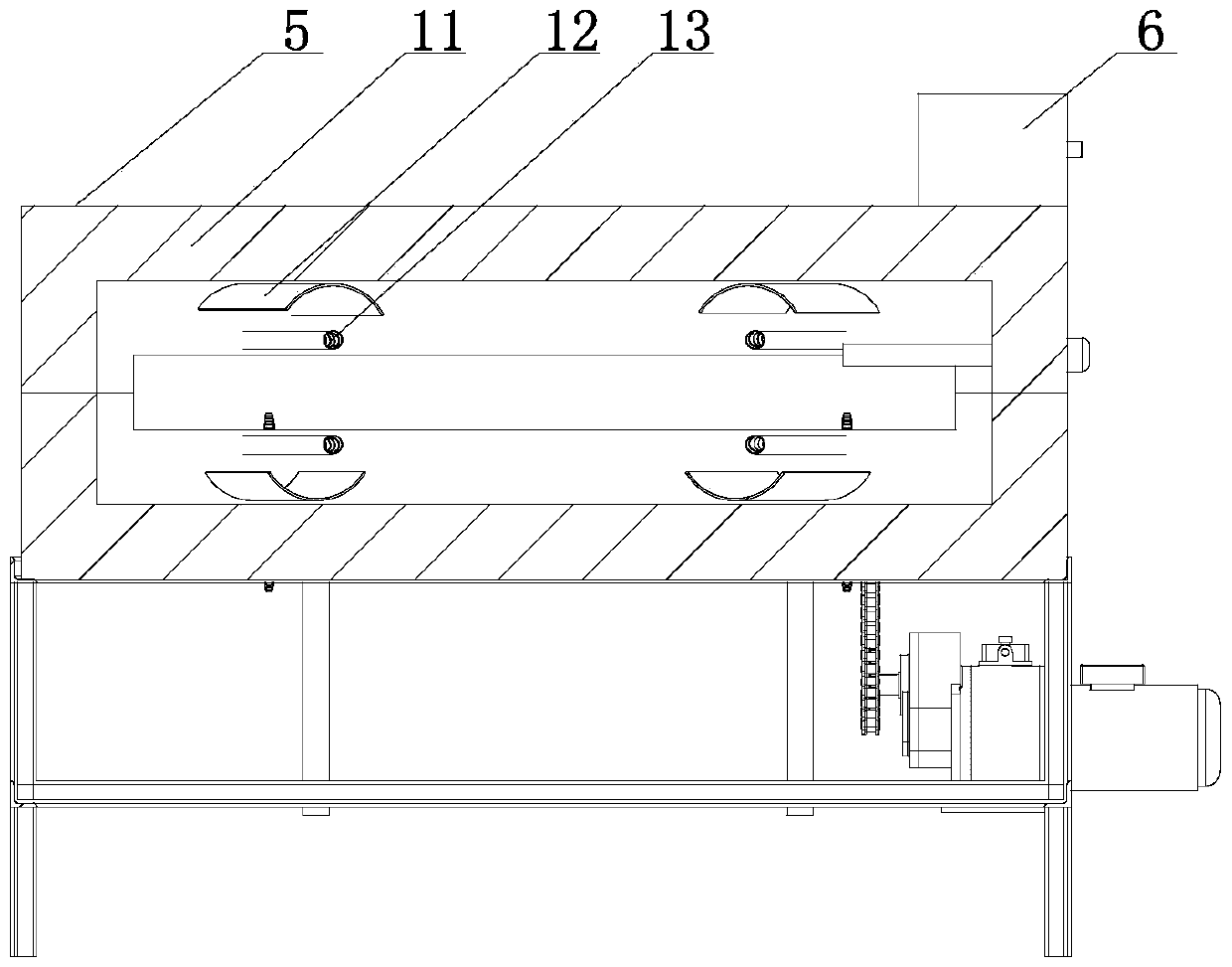

[0033] Such as Figure 1~3 As shown, the anti-corrosion and waterproof magnetic sensor production equipment includes a magnetic block placement device 1 arranged in sequence, a heat-shrinkable tube suit delivery device 2 and a heat-shrinkable industrial oven 3, and the heat-shrinkable industrial oven 3 includes a housing 5 and a magnetic strip conveyor. The device and the heating lamp tube 13, the magnetic strip conveying device runs through the shell 5 transversely, the corresponding magnetic strip conveying device is provided with the heating lamp tube 13, and the corresponding heating lamp tube 13 is provided with the mirror reflection plate 12.

[0034] When working, first place the magnetic block on the iron bar through the magnetic block placement device 1 to form a magnetic strip, the magnetic strip is removed by the operator and the heat shrinkable tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com