Method of Determining the Optimum Water Content of Filled Soil at the Same Energy Level Using Ramping-Sinking Ratio

A technology of optimal water content and tamping-sink ratio, applied in soil protection, construction, special data processing applications, etc., can solve problems such as the impact of tamping efficiency, with simple methods, strong operability, and clear physical meaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention utilizes the tamp-sink ratio to determine the optimal water content of the filling soil at the same energy level, through the tamping test of filling soils with various water contents at the same energy level, respectively calculate the ramming values corresponding to the filling soils with various water contents Depth ratio, drawing the tamping times-tamping-sink ratio curves of filling soil with various water contents for comparison to determine the optimal water content;

[0030] The tamping times-tamping ratio curve corresponding to each water content is obtained by the following method:

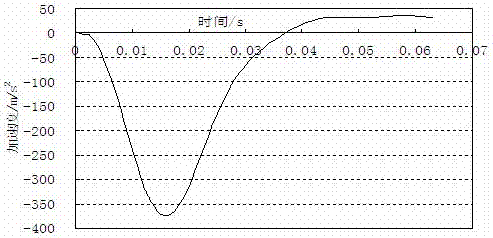

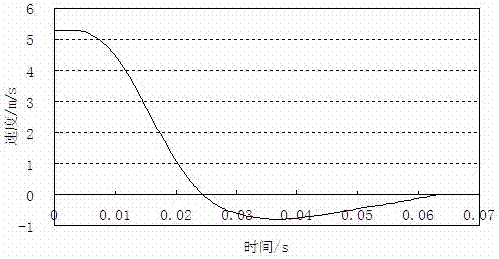

[0031] a) Prepare a kind of filling soil with water content, install an acceleration sensor on the top center of the rammer to carry out the ramming test, and record the dynamic acceleration data of each hit of the rammer through the dynamic test collector, and calculate the stroke of the rammer by integral value S;

[0032] b) Use a level to measure the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com